Method for preparing ternary sulfide and quaternary sulfur oxide phosphor powder

A phosphor and red phosphor technology, applied in chemical instruments and methods, luminescent materials, photovoltaic power generation, etc., can solve the problems of unfavorable production, environmental protection, cumbersome operation steps, etc., and achieve the effect of short reaction time and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

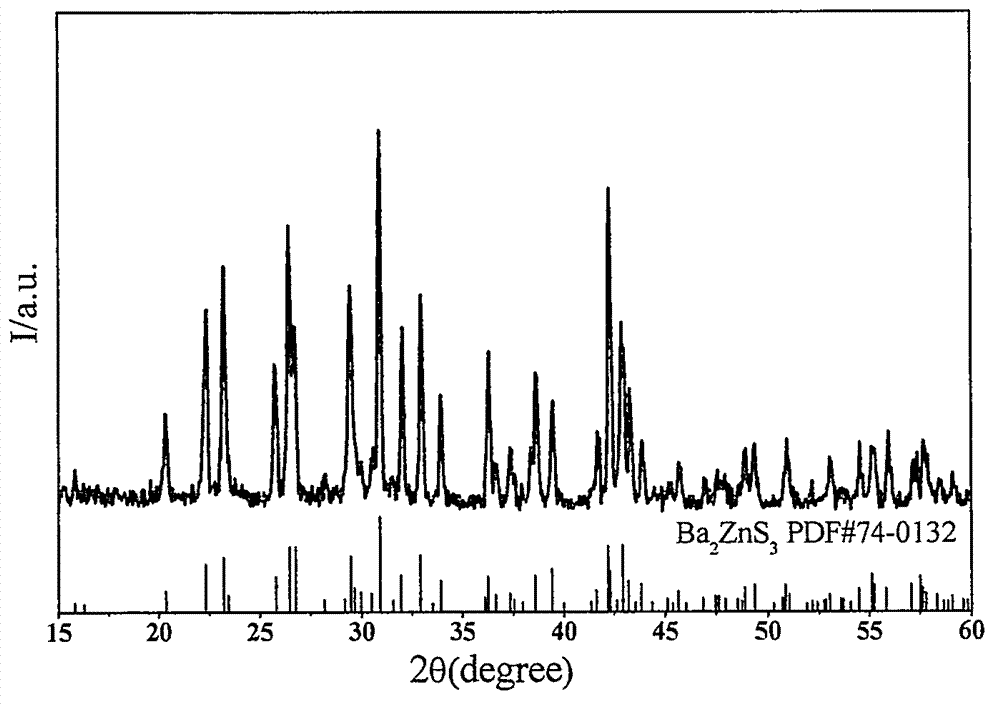

[0043] Example 1: Ba 2 ZnS 3 Synthesis

[0044] Ingredients: Accurately weigh BaSO according to stoichiometric ratio 4 1.8671g, ZnO 0.6511g, carbon powder 0.2402g, then fully ground in a mortar and set aside.

[0045] Synthesis: The synthesis method adopts the traditional high-temperature solid-phase method. Put the uniformly ground raw materials in the batching process into the crucible, place the crucible in a tube furnace, calcinate at 1000°C for 2.5 hours in a nitrogen atmosphere, and cool naturally to room temperature to obtain the desired phosphor.

example 2

[0046] Example 2: Ba 1.99 Zn 0.99 S 3 :1.0%Eu 2+ , 1.0% Mn 2+ Synthesis

[0047] Ingredients: (1) Accurately weigh BaSO according to the stoichiometric ratio 4 4.6445g, carbon powder 0.6002g, placed in an evaporating dish, mixed; (2) Accurately pipette 2.0ml of EuCl with a concentration of 0.05mol / L according to the stoichiometric ratio 3 solution and 0.5ml of MnCl with a concentration of 0.2mol / L 2 solution, added to the mixture in the evaporating dish in step (1), and stirred evenly with a glass rod; (3) the raw material mixture was placed in an oven to dry, and after drying, ZnS 0.9745g was accurately weighed in molar ratio, and then Grind thoroughly in a bowl and set aside.

[0048] Synthesis: The synthesis method adopts the traditional high-temperature solid-phase method. Put the uniformly ground raw materials in the batching process into the crucible, place the crucible in a tube furnace, calcinate at 1000°C for 3 hours in a nitrogen atmosphere, and cool naturall...

example 3

[0049] Example 3: Ba 1.396 Sr 0.6 ZnS 3 :0.4%Eu 2+ Synthesis

[0050] Ingredients: (1) Accurately weigh BaSO according to the stoichiometric ratio 4 3.2581g, carbon powder 0.5993g, SrSO 4 1.1021g was placed in an evaporating dish and mixed. (2) Use a pipette to accurately pipette 4.0ml of EuCl with a concentration of 0.01mol / L according to the stoichiometric ratio 3 Add the solution to the mixture in the evaporating dish in step (1), and stir evenly with a glass rod. (3) Dry the raw material mixture in an oven, accurately weigh 0.9745 g of ZnS according to the molar ratio after drying, and then fully grind it in a mortar for use.

[0051] Synthesis: The synthesis method adopts the traditional high-temperature solid-phase method. Put the uniformly ground raw materials in the batching process into the crucible, place the crucible in a tube furnace, calcinate at 950°C for 4 hours in a nitrogen atmosphere, and cool naturally to room temperature , to obtain the desired ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com