Method for extracting xylose, arabinose and galactose from xylose fermentation broth or xylose mother liquor

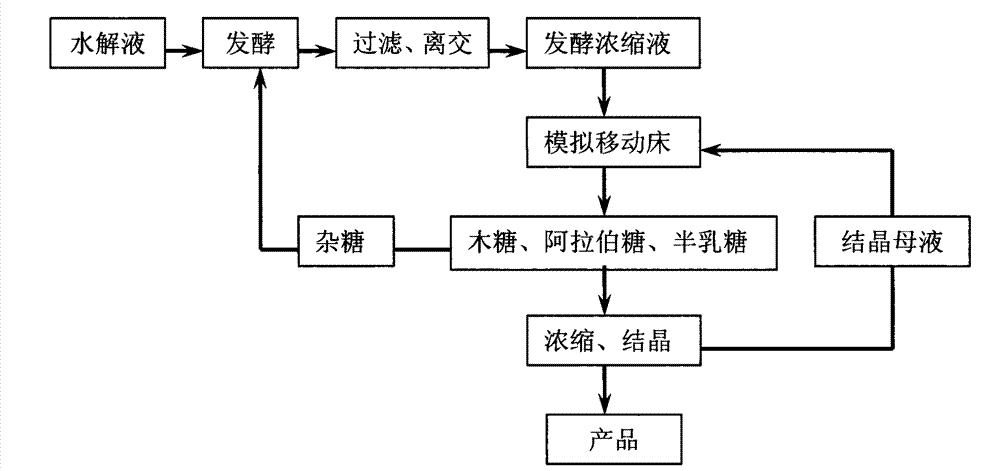

A technology of xylose mother liquor and arabinose, which is applied in the field of simulated moving bed chromatography, can solve the problems of reducing product yield, resource and energy consumption, complex pretreatment, etc., achieves mature process conditions, realizes zero discharge, and has a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

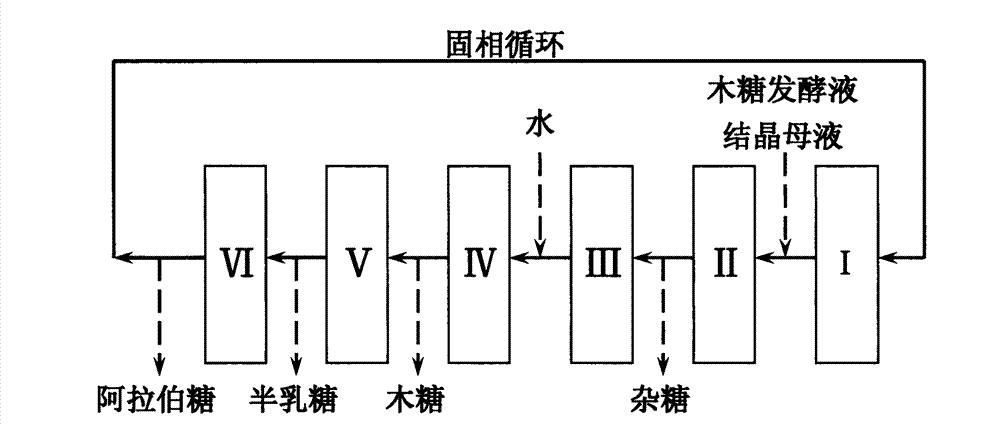

[0017] After the hydrolyzed liquid fermented, filter to remove impurities such as protein and yeast, ion exchange removes the salinity in the fermented liquid, obtain the xylose fermentation concentrated liquid (wherein xylose~60%; ~12%, arabinose ~21%), this solution enters the simulated moving bed separation, the separation conditions are as follows: the separation temperature is controlled at 70°C, the feed flow rate of the fermentation broth is 5cm / min, and the flow velocity of the eluting water is 20cm / min min, the system reaches equilibrium after 24 hours of feed operation, and the output of the three components is as follows:

[0018] 1) Xylose part: the refractive concentration is 27% (the volume is twice that of the feed solution); the purity of xylose in the solution is 91%, the purity of galactose is 3%, and the purity of arabinose is 1%;

[0019] 2) Galactose part: the refractive concentration is 7% (1.5 times the volume of the feed solution); the purity of xylose ...

Embodiment 2

[0023] After mixing the crystallization mother liquor of xylose, arabinose and galactose, the refractive concentration is 68% (wherein xylose ~ 62%; galactose ~ 10%, arabinose ~ 20%) into the simulated moving bed separation, the separation conditions are as follows: separation temperature The control is 75°C, the feeding flow rate of the crystallization mother liquor is 3cm / min, the flow rate of the eluting water is 12cm / min, and the system reaches equilibrium after 24 hours of feeding operation, and the discharge conditions of the three components are as follows:

[0024] 1) Xylose part: refractive concentration 32% (volume is 2 times of feed solution); xylose purity in solution is 93%, galactose purity is 2%, arabinose purity is 1%;

[0025] 2) Galactose part: the refractive concentration is 5% (1.5 times the volume of the feed solution); the purity of xylose in the solution is 24%, the purity of galactose is 65%, and the purity of arabinose is 5%;

[0026] 3) Arabinose part...

Embodiment 3

[0029] Fermentation concentrate and crystallization mother liquor are mixed according to the volume ratio of 3:1, and the refractive concentration of the mixed liquor is ~60% (including xylose ~60%, galactose ~11%, arabinose ~22%) into the simulated moving bed , the separation conditions are as follows: the separation temperature is controlled at 70 ° C, the feed flow rate of the crystallization mother liquor is 4 cm / min, the flow rate of the eluting water is 16 cm / min, the system reaches equilibrium after 24 hours of feed operation, and the discharge conditions of the three components as follows:

[0030] 1) Xylose part: the refractive concentration is 30% (twice the volume of the feed solution); the purity of xylose in the solution is 90%, the purity of galactose is 3%, and the purity of arabinose is 2%;

[0031] 2) Galactose part: the refractive concentration is 6% (1.5 times the volume of the feed solution); the purity of xylose in the solution is 22%, the purity of galact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com