Method for preparing hyperoside and isoquercitrin simultaneously from dogbane leaves

A technology of isoquercitrin and hyperoside, which is applied in the fields of chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., can solve problems such as unsuitable for large-scale production, low product yield, complicated process, etc. Achieve the effect of fast adsorption speed, large adsorption capacity and simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

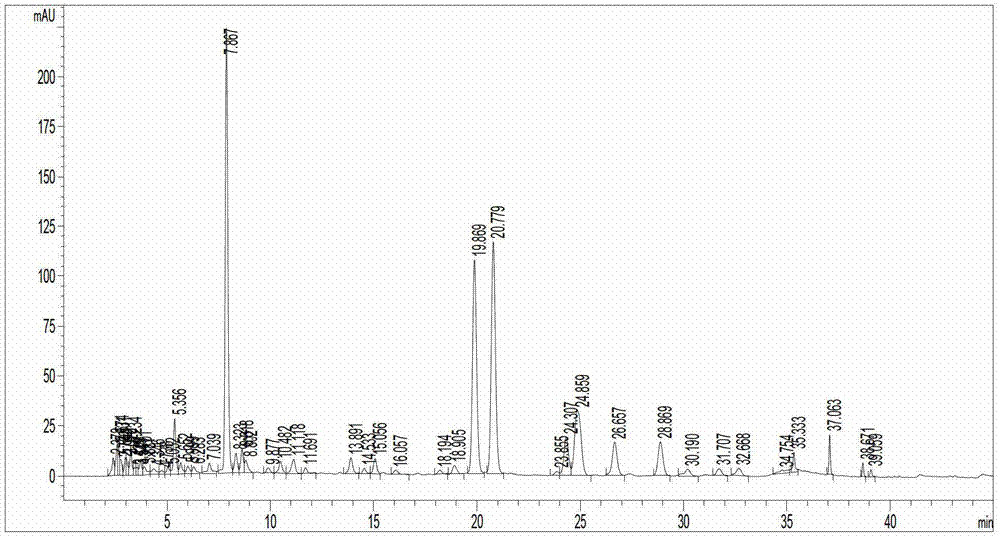

[0036] (1) Extraction: take 500g of Apocynum basil leaves, dry and pulverize them, add 5L of methanol with a volume fraction of 70%, heat and reflux for extraction 3 times, each time for 2 hours, combine the extracts, filter the extracts, concentrate under reduced pressure and recover the organic solvent to obtain Extract, add water to dissolve the extract, extract 3 times with an equal volume of petroleum ether after dissolving, dilute the water phase after extraction to a concentration of 10g / L, and mix well to obtain the intermediate product A. Its high-performance liquid chromatogram is as follows: figure 1 .

[0037](2) Separation of macroporous resins: Pass the intermediate product A at a flow rate of 3BV / h through AB-8 resin columns filled with 3-stage serial series treated according to conventional methods, and dynamically adsorb to saturation, wherein each series of macroporous adsorption resins The diameter-to-height ratio of the column is 1:8. Rinse the series adso...

Embodiment 2

[0043] (1) Extraction: dry and pulverize 1Kg of apocynum leaves, add 15L of 85% methanol, heat and reflux 3 times, 3 hours each time, combine the extracts, filter the extracts, concentrate under reduced pressure and recover the organic solvent to obtain extracts, extracts Add water to dissolve, extract 4 times with an equal volume of petroleum ether, dilute the aqueous phase to a concentration of 8g / L, and mix well to obtain the intermediate product A.

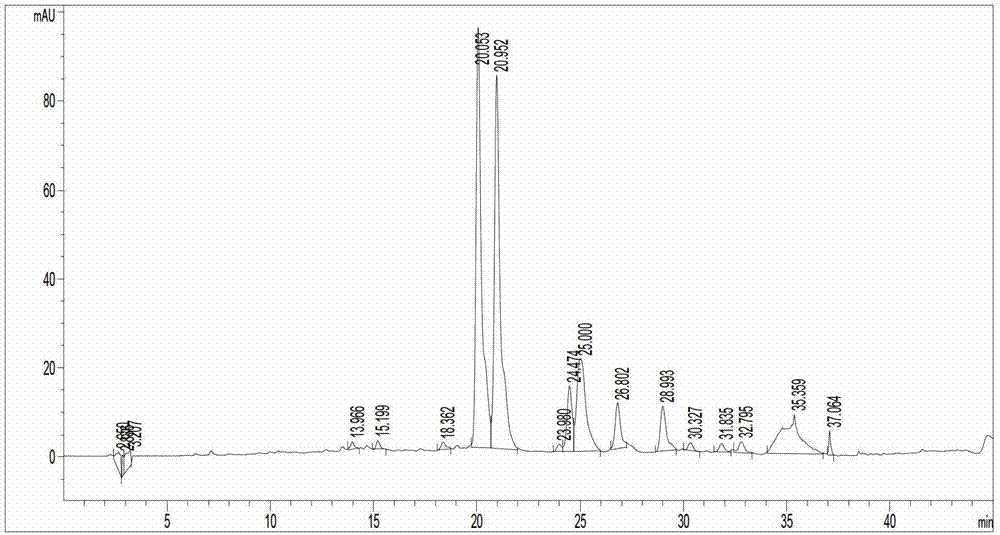

[0044] (2) Separation of macroporous resin: pass the intermediate product A at a flow rate of 3BV / h through a resin column filled with a combination of AB-8 and X-5 treated in a conventional manner in four stages in series, and dynamically adsorb to saturation. The diameter-to-height ratio of the macroporous adsorption resin columns connected in series is 1:10. Rinse the combined resin column of AB-8 and X-5 with distilled water at a flow rate of 7BV / h, and elute until no impurities flow out. Rinse the tandem resin column wit...

Embodiment 3

[0048] (1) Extraction: 5Kg of apocynum leaves were dried and pulverized, added 50L of 85% methanol, extracted 3 times by ultrasound, 1 hour each time, combined the extracts, filtered the extracts, concentrated under reduced pressure and recovered organic solvents to obtain extracts, extracts Add water to dissolve, extract 4 times with an equal volume of petroleum ether, dilute the water phase to a concentration of 10g / L, and mix thoroughly to obtain the intermediate product A.

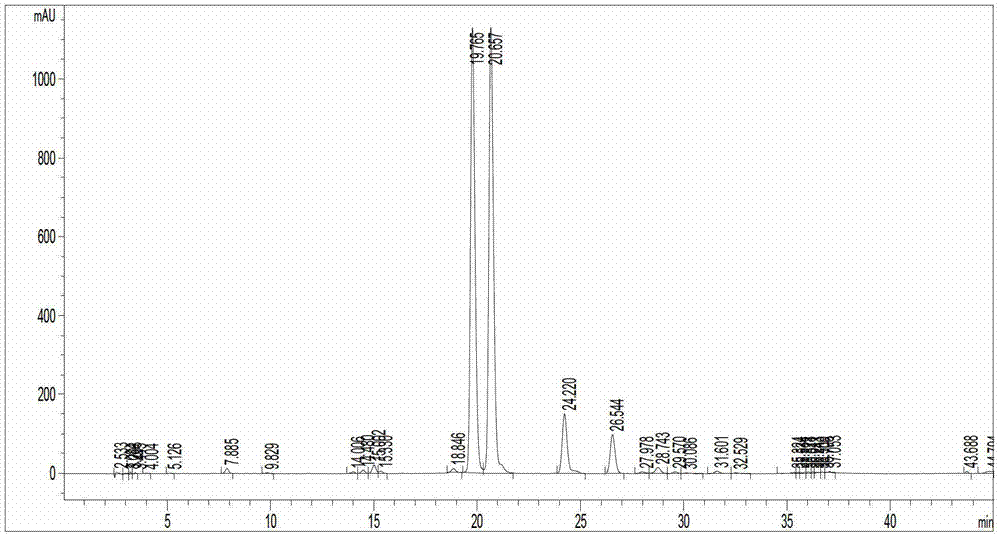

[0049] (2) Separation of macroporous resins: Pass the intermediate product A at a flow rate of 5BV / h through AB-8 resin columns filled with 5 stages in series treated according to conventional methods, and dynamically adsorb to saturation, in which each series of macroporous adsorption resins The diameter-to-height ratio of the column is 1:6. Rinse the AB-8 macroporous resin series adsorption column with distilled water at a flow rate of 10BV / h, and elute until no impurities flow out. Rinse the tandem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com