Method for brazing SiO2f/SiO2 composite ceramic and metal material

A technology of composite ceramics and metal materials, which is applied in the field of welding, can solve the problems of the lack of effective methods to relieve the thermal stress of joint welding, and achieve the effects of reducing residual thermal stress, avoiding cracking, and avoiding poor thermal expansion coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

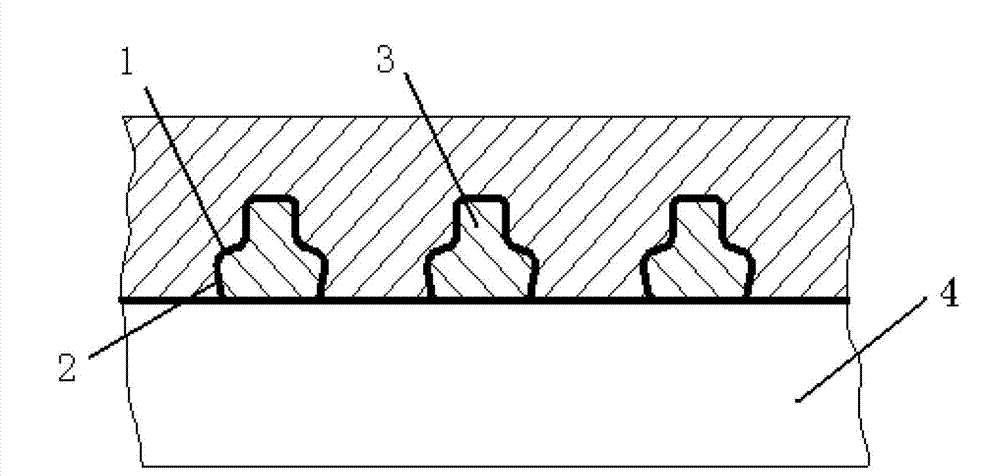

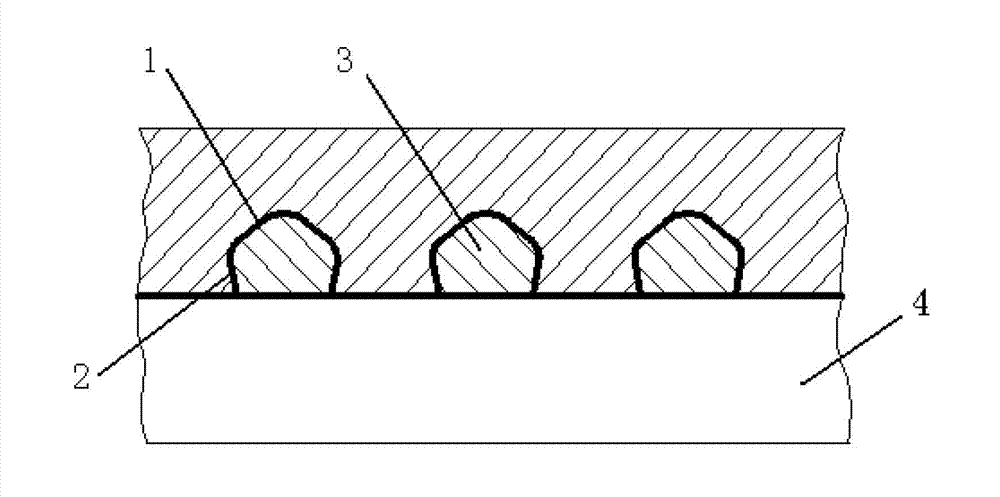

[0027] See attached Figure 1~2 As shown, before welding, the SiO 2f / SiO 2 The welded surface of the composite ceramic is processed with a through-shaped open groove 1, the shape of the lower part of the open groove 1 is approximately conical or square, and the two side walls 2 of the open groove 1 are in contact with the welded SiO 2f / SiO 2 The included angle of the composite ceramic surface is 60°~80°; the opening groove (1) is in SiO 2f / SiO 2 The surface of the composite ceramic to be welded is in a through shape, the opening width of the opening groove (1) is 3.0mm-15.0mm, the opening depth is 3.0mm-15.0mm, and the distance between adjacent opening grooves (1) is 5.0mm- 15.0mm;

[0028] Next, separately process the mosaic block 3 whose size matches the cross-sectional shape of the above-mentioned opening groove 1. The material of the mosaic block 3 can be metal Cu, or Nb, or Mo, or Fe, or Ti, or W, or respectively An alloy based on one of Cu, Ni, Nb, Mo, Fe, Ti, W...

Embodiment 2

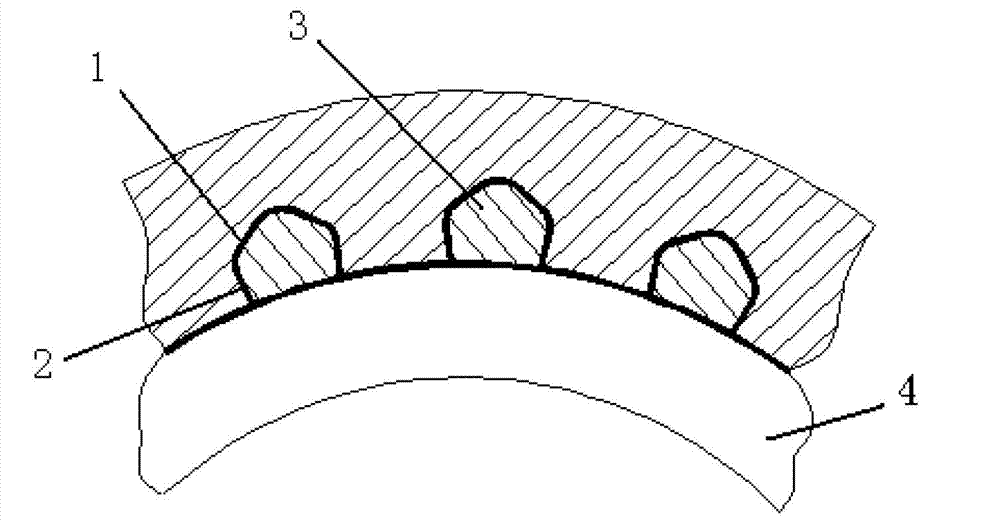

[0032] See attached image 3 As shown, before welding, the SiO 2f / SiO 2 The annular welded surface of the composite ceramic is processed with an open groove 1, the shape of the lower part of the open groove 1 is approximately conical, and the two side walls 2 of the open groove 1 are in contact with the welded SiO 2f / SiO 2 The included angle of the composite ceramic surface is 60°~80°; the opening groove (1) is in SiO 2f / SiO 2 The surface of the composite ceramic to be welded is in a through shape, the opening width of the opening groove (1) is 3.0mm-15.0mm, the opening depth is 3.0mm-15.0mm, and the distance between adjacent opening grooves (1) is 5.0mm- 15.0mm;

[0033] Next, separately process the mosaic block 3 whose size matches the cross-sectional shape of the above-mentioned opening groove 1. The material of the mosaic block 3 can be metal Cu, or Nb, or Mo, or Fe, or Ti, or W, or respectively An alloy based on one of Cu, Ni, Nb, Mo, Fe, Ti, W, or the metal mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com