Sewage biochemical treatment integrated device and system and process method

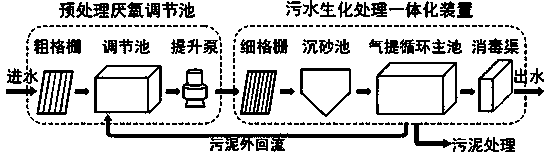

A biochemical treatment and sewage technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, energy and wastewater treatment, etc. It can shorten the sewage treatment process, simplify the operation management, and reduce the project investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

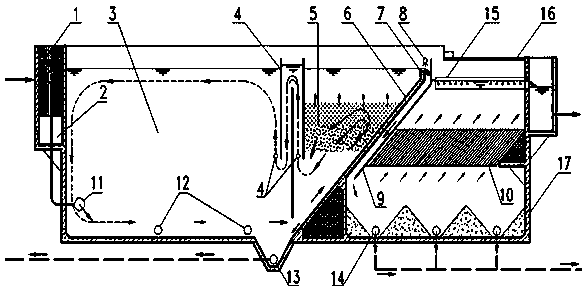

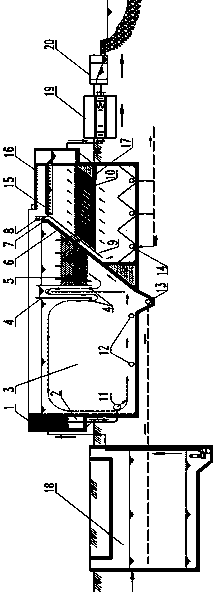

[0035] Below in conjunction with accompanying drawing, the present invention is further described: as figure 2 As shown, the sewage biochemical treatment integrated device of the present invention is an air lift reflux circulation pool, including a pool body 17, an oblique flow guide partition 6 is arranged in the pool body 17, and an aeration is provided on one side of the oblique flow guide partition 6. Component 12, vertical airlift return component 4, an external return sludge discharge bucket 13 is arranged between the aeration component 12 and the inclined flow guide partition 6; Assembly 10, an oblique deflector 9 parallel to the oblique deflector baffle 6, a chemical spray perforated pipe 8 is arranged above the water inlet of the oblique deflector 9, and a settling sludge row is arranged below the sedimentation assembly 10 A triangular weir 15 and a movable shading plate 16 are arranged sequentially above the mud bucket 14 and the settling assembly 10 from bottom to ...

Embodiment 2

[0053] Such as figure 2 As shown, an integrated sewage biochemical treatment device is an air lift reflux circulation pool, which includes a pool body 17. An oblique flow guide partition 6 is arranged inside the pool body 17, and an aeration is provided on one side of the oblique flow guide partition 6. Component 12, vertical airlift return component 4, an external return sludge discharge tank 13 is provided between the aeration component 12 and the inclined flow guide partition 6; Assembly 10, an oblique guide pipe 9 parallel to the oblique guide partition 6, a chemical spray perforated pipe 8 is arranged above the water inlet of the oblique guide pipe 9, and a settling sludge row is arranged below the sedimentation assembly 10 The mud tank 14 is provided with a perforated water collection tank 15 and a movable shading plate 16 sequentially from bottom to top above the sedimentation assembly 10 .

[0054] The water inlet of the pool body is also provided with a fine grid 1 ...

Embodiment 3

[0071] Such as figure 2 As shown, an integrated sewage biochemical treatment device is an air lift reflux circulation pool, which includes a pool body 17. An oblique flow guide partition 6 is arranged inside the pool body 17, and an aeration is provided on one side of the oblique flow guide partition 6. Component 12, vertical airlift return component 4, an external return sludge discharge hopper 13 is arranged between the aeration component 12 and the inclined flow guide partition 6; Assembly 10, an oblique deflector 9 parallel to the oblique deflector baffle 6, above the water inlet of the oblique deflector 9 is provided with a chemical spray perforated pipe 8, and below the settling assembly 10 is provided with a settling sludge row The mud bucket 14 is provided with a perforated water collection tank 15 and a movable shading plate 16 sequentially from bottom to top above the sedimentation assembly 10 .

[0072] The water inlet of the pool body is also provided with a fine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com