Soldering/diffusion welding hybrid welding method for cemented carbide and alloy steel

A cemented carbide and composite welding technology, used in welding equipment, welding equipment, welding/welding/cutting objects, etc., can solve the problems of large residual stress, uneven heating, and easy damage of joints in vacuum diffusion welding, and achieve solid solution. The effect of strengthening the weld area, low residual stress, and low heating and cooling rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

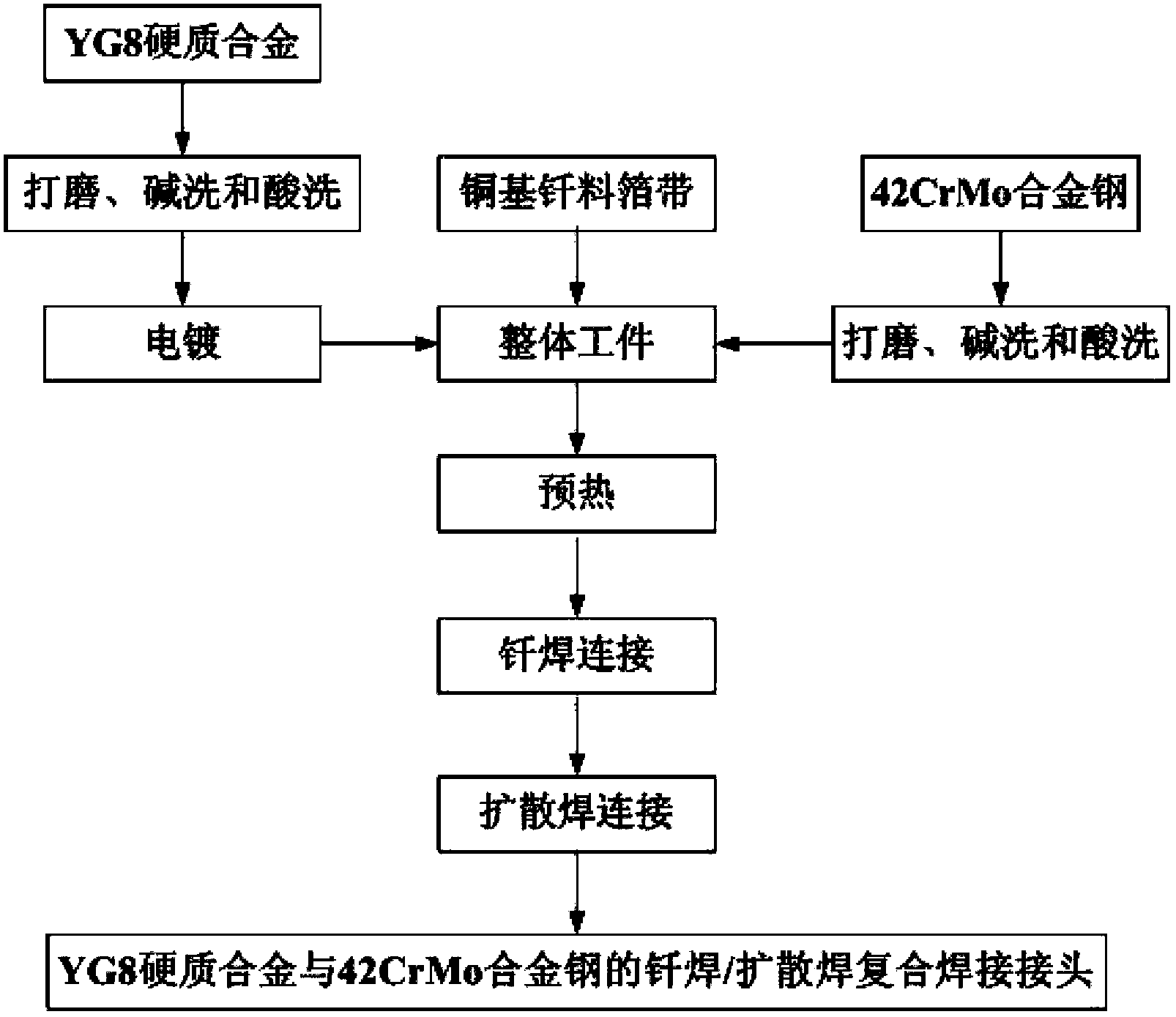

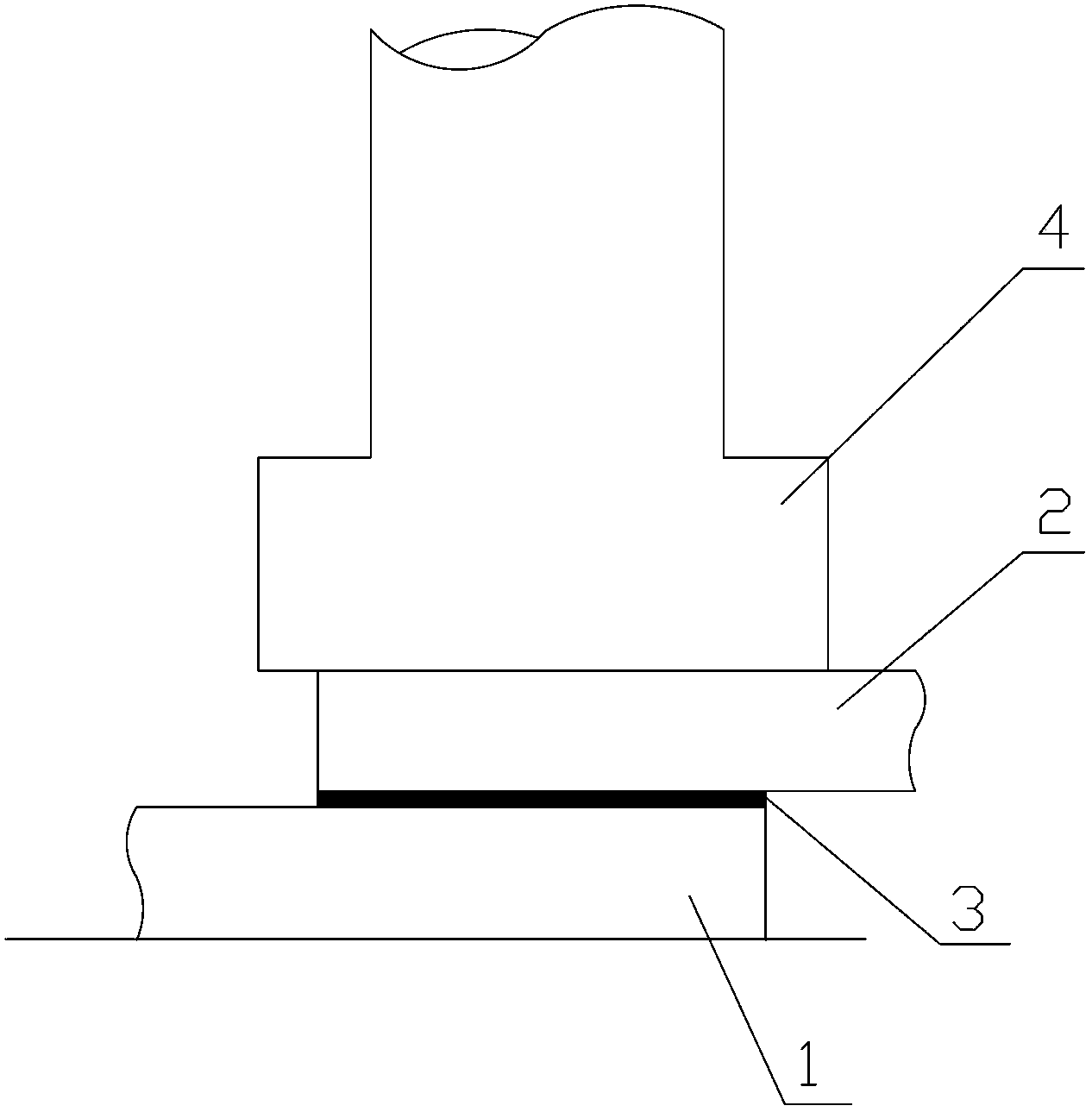

[0040] The brazing / diffusion welding composite welding method of cemented carbide and alloy steel of the present embodiment comprises the following steps:

[0041] Step 1. First, the YG8 cemented carbide strip 1 and the 42CrMo alloy steel strip 2 are roughly ground with a grinding wheel, and then polished with 80#, 600# and 1000# metallographic sandpaper in turn, and then processed by alkali cleaning and pickling; The pickled YG8 hard alloy strip 1 is placed in a plating tank filled with nickel-based electroplating solution, with the nickel strip as the anode and the YG8 hard alloy strip 1 as the cathode, at a temperature of 50°C and a current density of 7A / dm 2 , the distance between the nickel strip and the YG8 hard alloy strip 1 is electroplated for 60min under the condition of 40mm, and a nickel coating with a thickness of 50 μm is obtained on the surface of the YG8 hard alloy strip 1; the nickel-based electroplating solution is composed of nickel sulfate, boric acid , th...

Embodiment 2

[0050] The brazing / diffusion welding composite welding method of cemented carbide and alloy steel in this embodiment is the same as that in Embodiment 1, except that the electroplating time in step 1 is 30 minutes, and the thickness of the nickel coating is 10 μm.

Embodiment 3

[0052] The brazing / diffusion welding composite welding method of cemented carbide and alloy steel in this embodiment is the same as that in Embodiment 1, except that the electroplating time in step 1 is 45 minutes, and the thickness of the nickel coating is 30 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com