Wire fusing method of laser liquid filling welding

A liquid filling and laser technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of poor weld quality, poor melting stability, and low welding efficiency, and achieve faster droplet transfer frequency and joint deformation The effect of small amount and lower wire feeding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

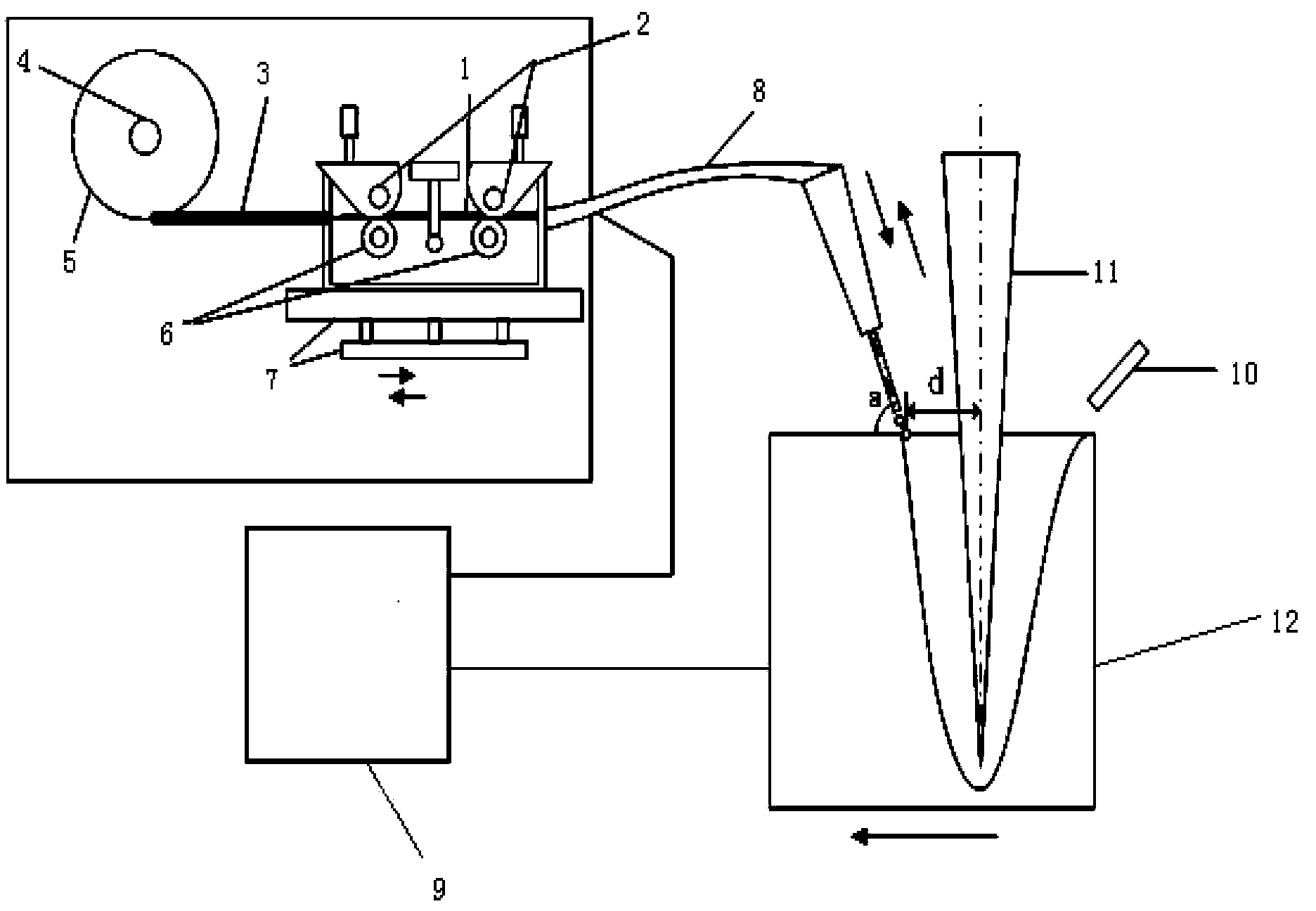

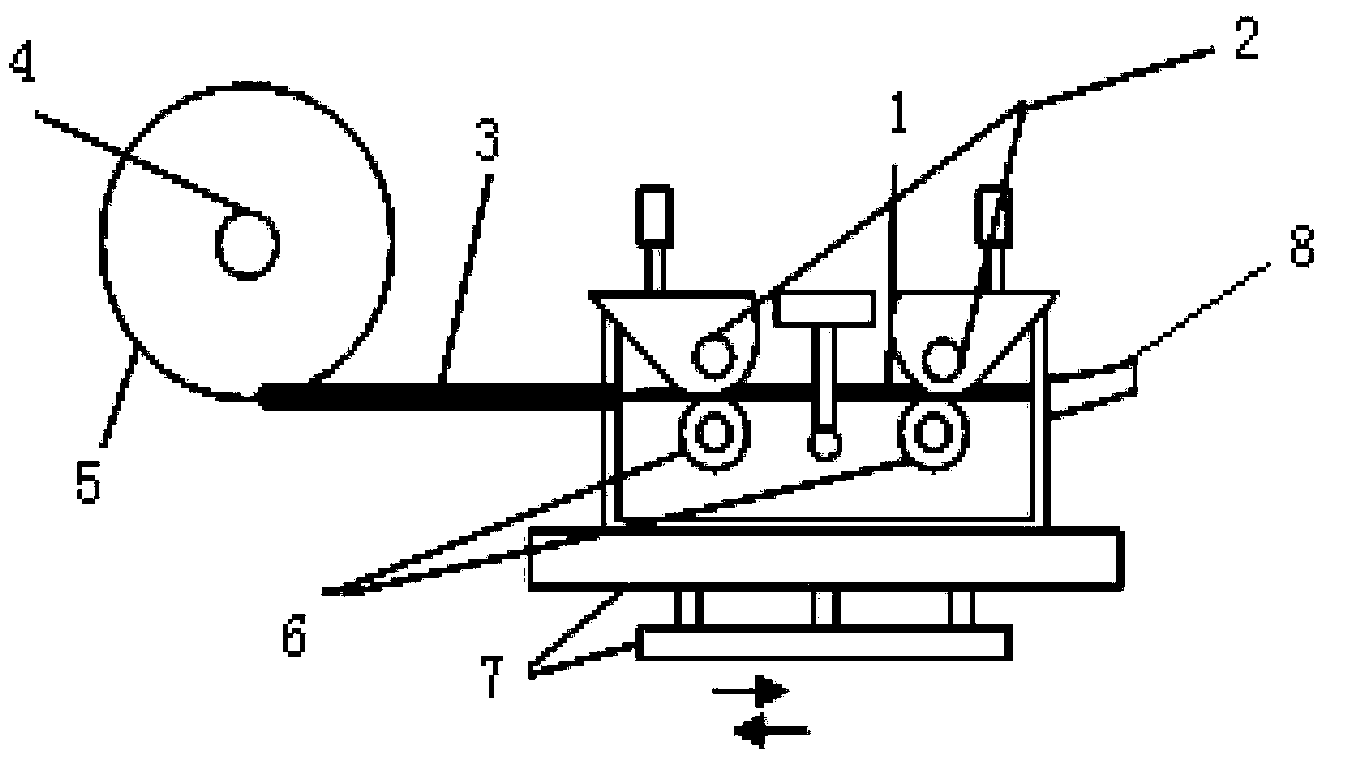

[0022] Specific embodiment one: a kind of fuse method of laser liquid filling welding in this embodiment is carried out according to the following steps:

[0023] 1. Connect the MIG welding torch to the vibrating wire feeding device. One pole of the TIG power supply is connected to the MIG welding torch, and the other pole is connected to the base material. The TIG power supply adopts the current output form of DC positive connection, DC reverse connection or AC;

[0024] 2. Start the laser to form a molten pool on the base material, and the input type of the laser is continuous output or pulse output;

[0025] 3. Ignite the auxiliary arc to heat the welding wire, and start the wire feeding device and the vibration device at the same time to ensure that the welding wire continues to melt under the action of the arc and continue to feed under the vibration state, wherein the wire feeding device is connected to the MIG welding torch;

[0026] 4. The droplet grows up gradually. W...

specific Embodiment approach 2

[0034] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the current of the TIG power source described in step 1 is 1A to 90A, and the arc striking method is high-frequency arc striking. arc, premelting the welding wire in front of the laser. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0035] Embodiment 3: This embodiment differs from Embodiment 2 in that the current of the TIG power supply in step 1 is 5A-80A. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com