Dedusting air door automatic switch device and dust collector with the same

A technology of automatic switch and air door, which is applied in the direction of cleaning methods, chemical instruments and methods, cleaning methods and utensils using gas flow, etc., which can solve the problems affecting the health of operators, affecting the cleanliness of production workshops, and affecting the cleanliness of laser lenses, etc. problem, to achieve the effect of simple structure, no space occupation, and prevention of dust backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

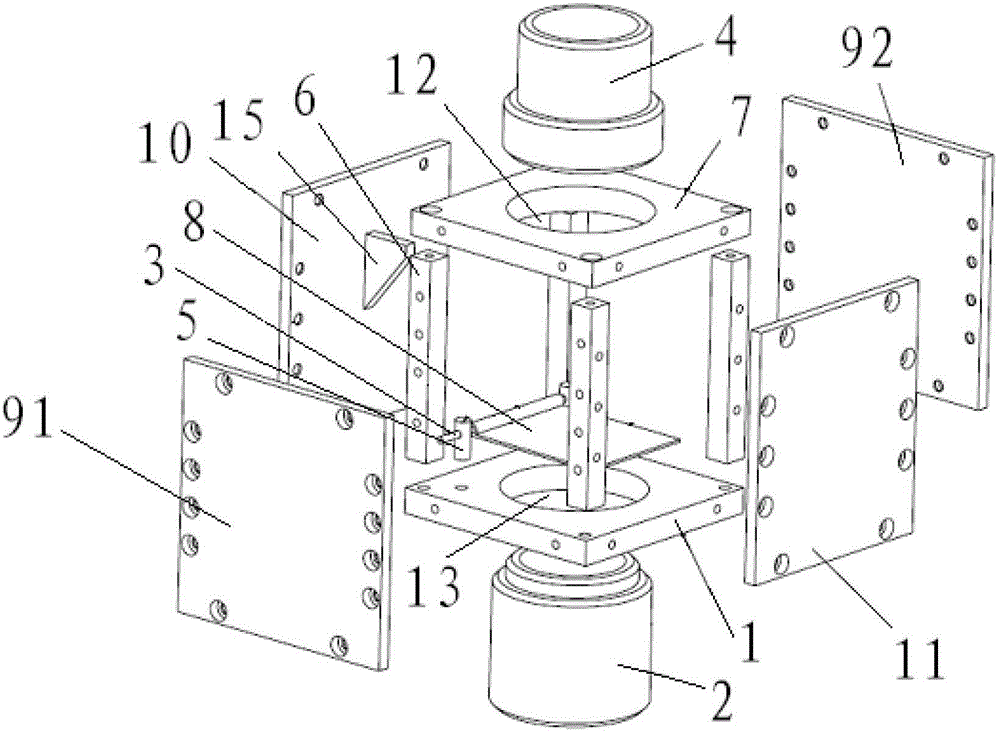

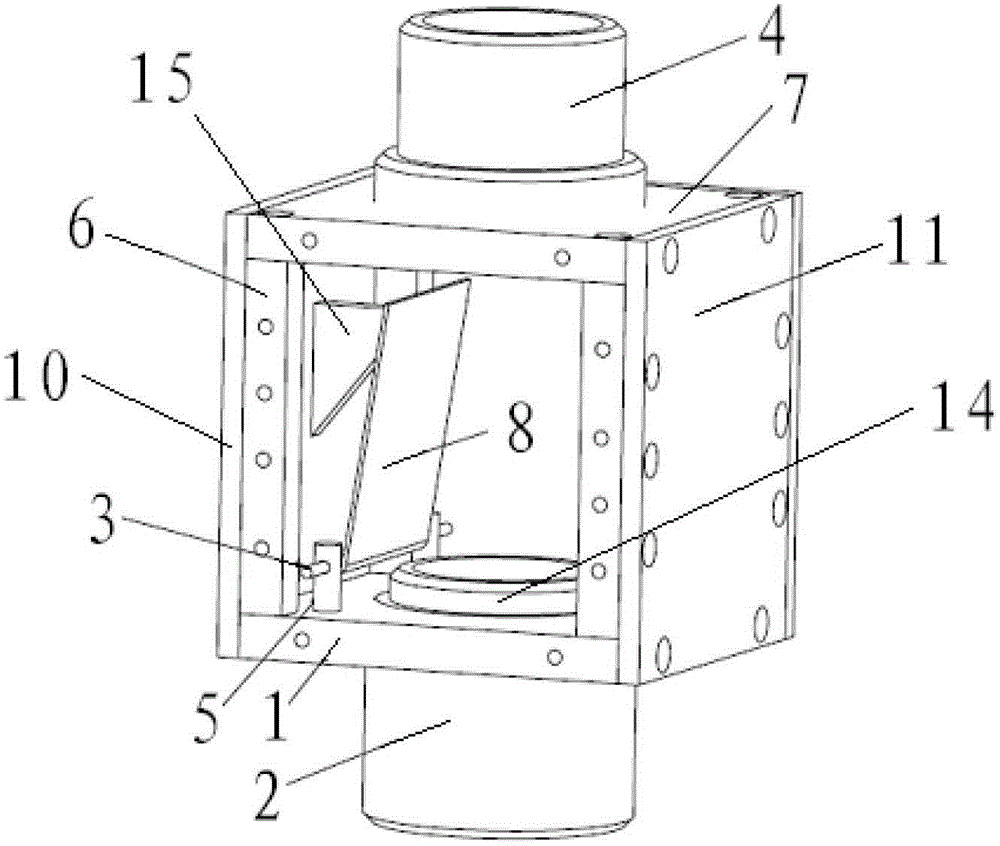

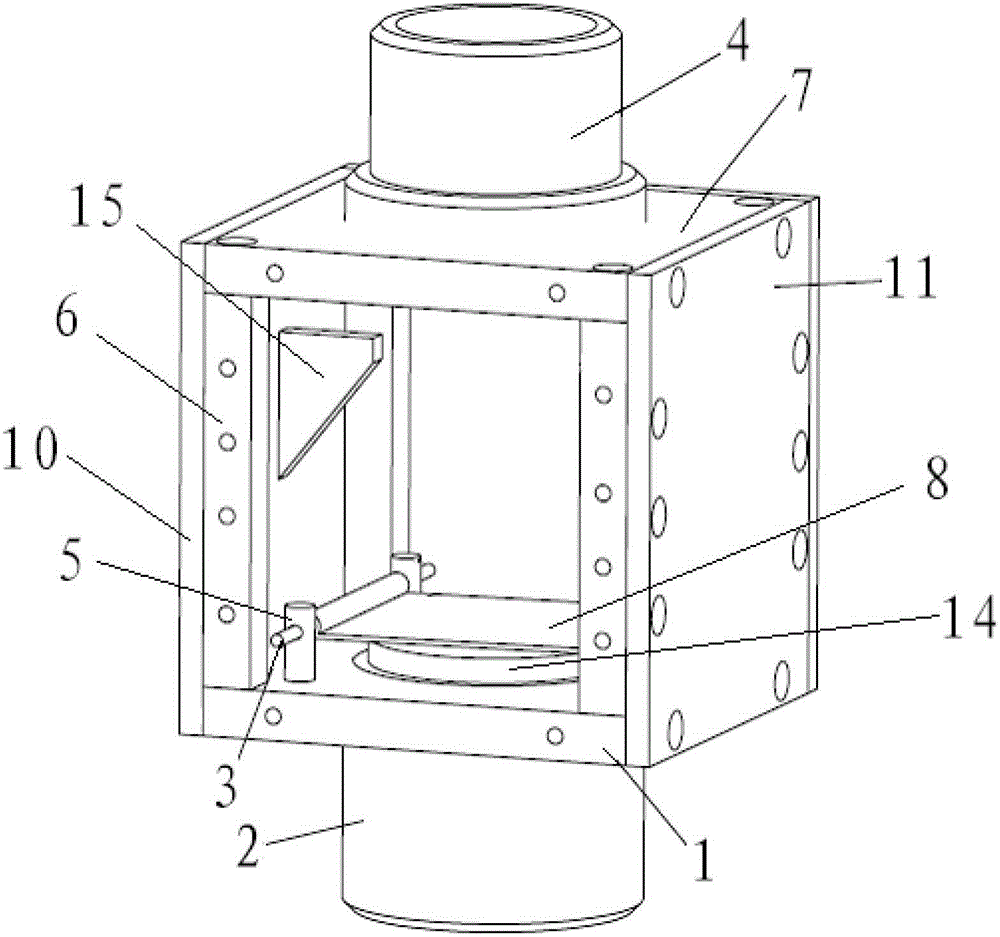

[0024] see Figure 1 to Figure 3 , the dust removal damper automatic switch device includes an upper cover plate 7, a lower cover plate 1, an upper connection end 4, a lower connection end 2, a flap shaft 3, a flap shaft support 5, four columns 6, a windshield 8, The front side plate 91, the rear side plate 92, the left side plate 10, the right side plate 11 and the limit plate 15; the upper cover plate 7 is provided with an upper air vent 12, and the lower cover plate 1 is provided with a lower air vent 13; Both the upper connecting end 4 and the lower connecting end 2 are of tubular structure; the limiting plate 15 is triangular in shape, and the upper part of the limiting plate extends into the air chamber longer than the lower part extends into the air chamber. The flap shaft 3 passes through the flap shaft bracket 5; the flap shaft bracket 5 is fixed on the lower cover plate 1 by threaded fasteners, and is located on the outside of the lower vent 13, and the four columns ...

Embodiment 2

[0029] A vacuum cleaner, the dust removal damper automatic switch device described in Embodiment 1 is arranged on the air outlet duct of the vacuum cleaner. Other structures of the vacuum cleaner adopt conventional vacuum cleaner structures, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com