Method for preparing P25/nitrogen-doped graphene composite material

A technology of nitrogen-doped graphene and composite materials, which is applied in the field of preparation of graphene-based composite materials, can solve the problems of not being able to obtain defect-free graphene in batches, and cannot obtain composite materials in large quantities, so as to achieve easy industrial production and simple preparation methods , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Weigh 55mg of graphite oxide and disperse it in 55mL of deionized water at room temperature. After the resulting mixture is dispersed evenly by ultrasound, add 55mg of P25 and 0.25mL of hydrazine hydrate solution (50%), and stir evenly to form a reaction solution; (2) Add the reaction solution into the reaction kettle, raise the temperature to 200°C, and react for 12 hours; (3) Cool the obtained product to room temperature, collect the product by centrifugation, wash the product with deionized water, and dry it at 70°C for 16 hours to obtain the P25 / nitrogen-doped graphene composite Material.

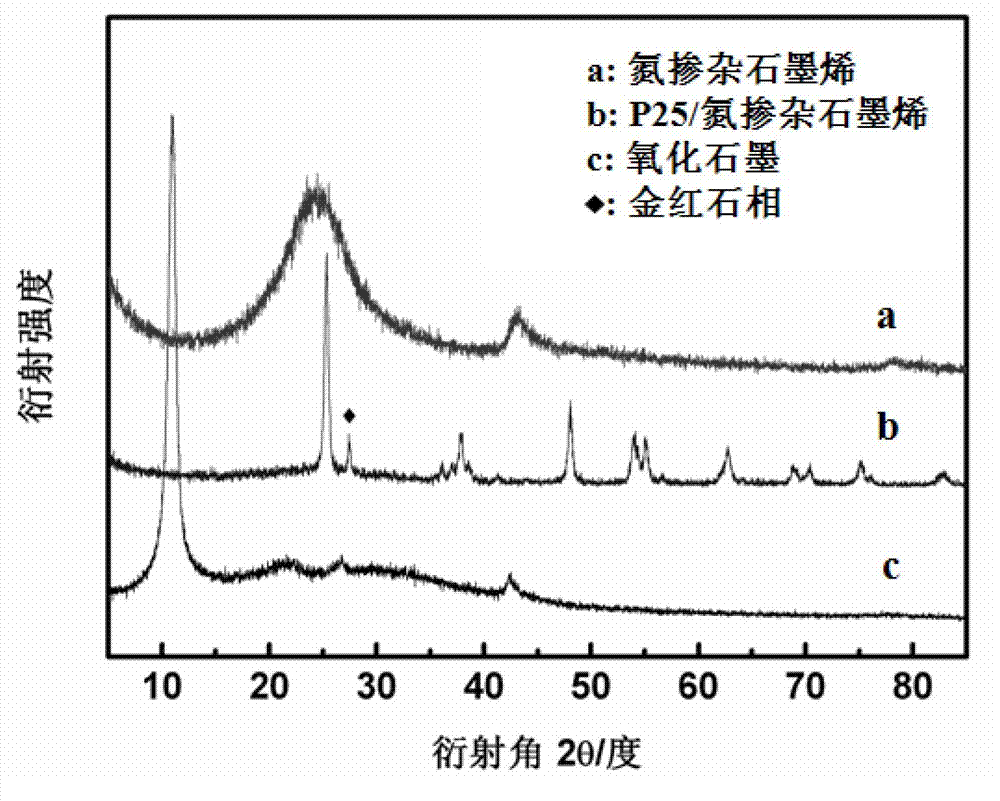

[0026] figure 1 It can be seen that the composite material contains P25 type titanium dioxide, and the graphite oxide is reduced to graphene, and doped with a certain amount of nitrogen atoms. . figure 2 It is a Raman spectrum comparison chart of the composite material and graphene oxide. It can be seen that the graphite oxide sheet is well reduced, and the obtained nitro...

Embodiment 2

[0028] (1) Weigh 30mg of graphite oxide and disperse it in 55mL of deionized water at room temperature. After the resulting mixture is dispersed evenly by ultrasonic, add 60mg of P25 and 0.05mL of hydrazine hydrate solution (50%), and stir evenly to form a reaction solution; (2) Add the reaction solution into the reaction kettle, raise the temperature to 180°C, and react for 18 hours; (3) Cool the obtained product to room temperature, collect the product by centrifugation, wash the product with deionized water, and dry it at 60°C for 18 hours to obtain the P25 / nitrogen-doped graphene composite Material. The hydrogen production rate of the composite material is about (3.0mL 氢气 min -1 g 催化剂 -1 ).

Embodiment 3

[0030] (1) Weigh 100mg of graphite oxide and disperse it in 55mL of deionized water at room temperature. After the resulting mixture is dispersed evenly by ultrasonic, add 50mg of P25 and 0.6mL of hydrazine hydrate solution (50%), and stir evenly to form a reaction solution; (2) Add the reaction solution into the reaction kettle, raise the temperature to 210°C, and react for 10 hours; (3) Cool the obtained product to room temperature, collect the product by centrifugation, wash the product with deionized water, and dry it at 80°C for 14 hours to obtain the P25 / nitrogen-doped graphene composite Material. The hydrogen production rate of the composite material is about (3.3mL 氢气 min -1 g 催化剂 -1 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com