Hollowed-out membrane used as hernia patch and preparation method thereof

A patch and hernia technology, which is applied in the application field of biomedical materials, can solve the problems of scattered thread ends, easy fluffing, and twisted hernia patch, and achieves the effects of good fit, small footprint, and low equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032](1) Take polyethylene (PE) as a raw material, and make a film by melt casting at a temperature of 250°C.

[0033] (2) Biaxially stretch the PE nascent film, the stretching ratio is 6 times, and the final thickness is 0.2mm.

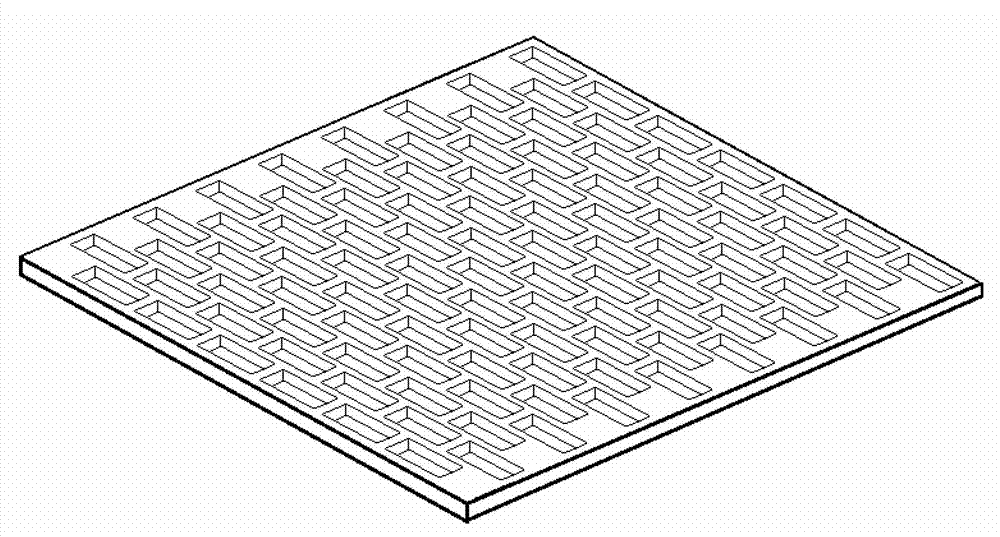

[0034] (3) Use the machine engraving method to punch holes in the film. The graphic design of the holes is rectangular, the width is 2mm, the aspect ratio is 2, and the edge width between the holes is 0.8mm, such as figure 2 shown.

[0035] (4) The hollowed-out film was flattened and heat-set at 90°C for 30 minutes to obtain a hollowed-out hernia patch with a tensile strength of 30 MPa and an elongation at break of 10%. It can be tailored appropriately according to actual needs during clinical application.

Embodiment 2

[0037] (1) Take polyethylene (PE) as a raw material, and make a film by melt casting at a temperature of 150°C.

[0038] (2) Biaxially stretch the PE nascent film, the stretching ratio is 1 times, and the final thickness is 1.0mm.

[0039] (3) The film is perforated by machine engraving. The graphic design of the hole is rectangular, the width is 1mm, the aspect ratio is 5, and the edge width between the holes is 0.2mm.

[0040] (4) The hollowed-out film was flattened and heat-set for 60 minutes at a temperature of 50°C to obtain a hollowed-out hernia patch with a tensile strength of 21 MPa and an elongation at break of 50%. It can be tailored appropriately according to actual needs during clinical application.

Embodiment 3

[0042] (1) Take polyethylene (PE) as a raw material, and make a film by melt casting at a temperature of 200 °C.

[0043] (2) Biaxially stretch the PE nascent film, the stretching ratio is 3 times, and the final thickness is 0.4mm.

[0044] (3) Use the machine engraving method to punch holes in the film. The graphic design of the holes is rectangular, the length is 20mm, the aspect ratio is 4, and the edge width between the holes is 5mm.

[0045] (4) Flatten and heat-set the hollowed-out film for 40 minutes at a temperature of 70°C to obtain a hollowed-out hernia patch with a tensile strength of 26 MPa and an elongation at break of 20%. It can be tailored appropriately according to actual needs during clinical application.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com