Amide ester internal electron and process

A technology of internal electron donor and electron donor, which is applied in the field of procatalyst composition, can solve problems such as limitations, and achieve the effect of improving catalyst activity and catalyst selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

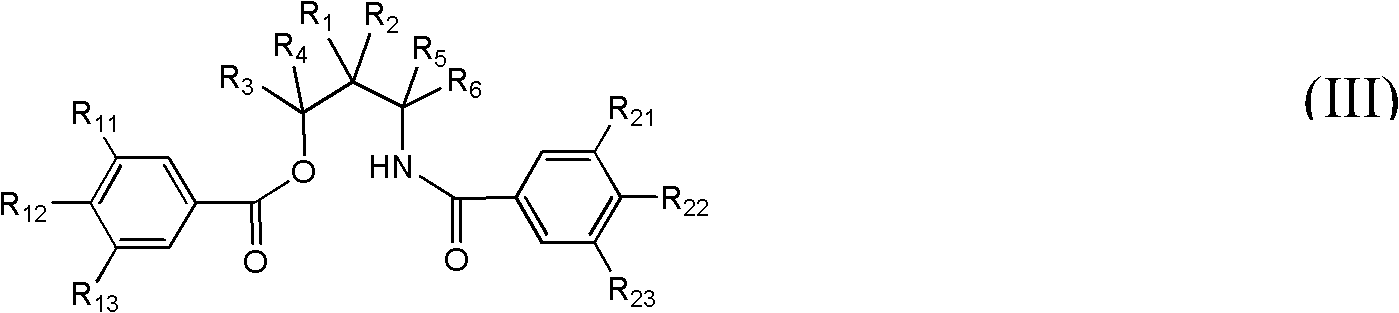

Method used

Image

Examples

Embodiment

[0152] 1. Synthesis of amide ester

[0153] Ethyl 2-cyano-2-isobutyl-4-methylpentanoate, and ethyl 2-cyano-2-isopropyl-3-methylbutanoate:

[0154]

[0155] A 500-ml round bottom flask was equipped with a magnetic stirrer and charged with ethyl 2-cyanoacetate (11.3 g, 0.1 mol) and anhydrous DMF (120 ml). To this stirred solution was added 1,8-diazabicyclo[5.4.0]undec-7-ene (DBU) (30.4 g, 0.2 mol, 1.0 equiv) in dry DMF (40 ml) dropwise The solution. After the addition was complete, the mixture was stirred for an additional hour. The flask was cooled in an ice-water bath and a solution of iodide (0.2 mol, 1.0 equiv) in DMF (40 ml) was added dropwise. The mixture was warmed to room temperature and stirred for an additional 14 hours until all starting material was converted to product (monitored by GC). The mixture was poured into ice water, and extracted with diethyl ether. The combined ether extracts were washed with water and brine, dried over magnesium sulfate. After f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com