High-density LED lamp structure

A technology of LED lamp structure and LED lamp beads, which is applied in lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of increased heat generation of lamps, aging of phosphor powder, easy deposition, etc., and achieve good heat dissipation performance , the effect of light and thin body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

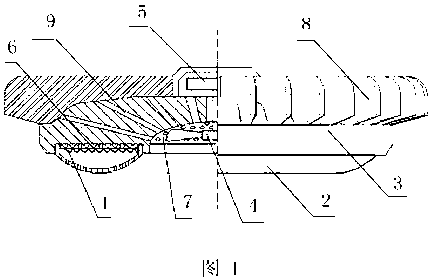

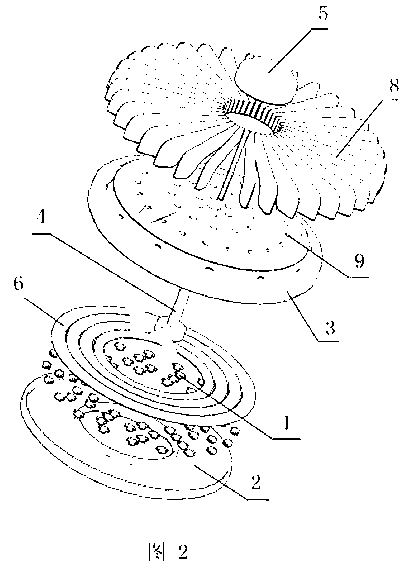

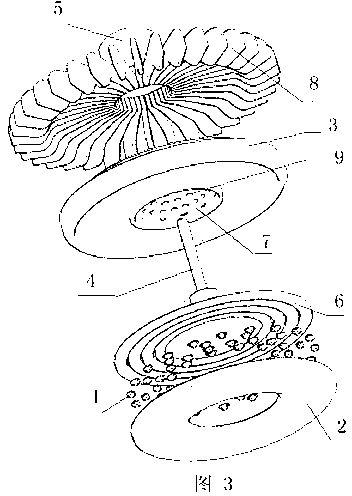

[0015] The present invention will be further elaborated below in conjunction with the accompanying drawings.

[0016] Such as Figure 1 to Figure 3 As shown, the high-density LED lamp is assembled by LED lamp beads 1, light distribution lampshade 2, heat sink 3, fan 4, ring-shaped aluminum substrate 6, drive circuit assembly 5 and rear cover, and each component is connected and assembled through heat sink 3 In one piece, the center of the bottom surface of the cooling body 3 is sunken inwardly to form a fan storage chamber 7. Several straight cylindrical air ducts 9 are formed in the body of the cooling body 3. The air ducts 9 are connected to the cooling body, and the air outlet port of the air duct 9 Distributed on the entire back of the heat sink, the air inlet port of the air duct 9 is only distributed on the inner wall of the fan storage cavity, the back of the heat sink 3 is evenly arranged around a number of cooling fins 8, and the drive circuit assembly 5 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com