Device and method for measuring radial deformation of tri-axial sample

A technology of radial deformation and measuring device, applied in the direction of measuring device, optical device, instrument, etc., can solve the problems of poor portability, sample disturbance, influence of radial deformation, etc., and achieve the effect of reducing error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

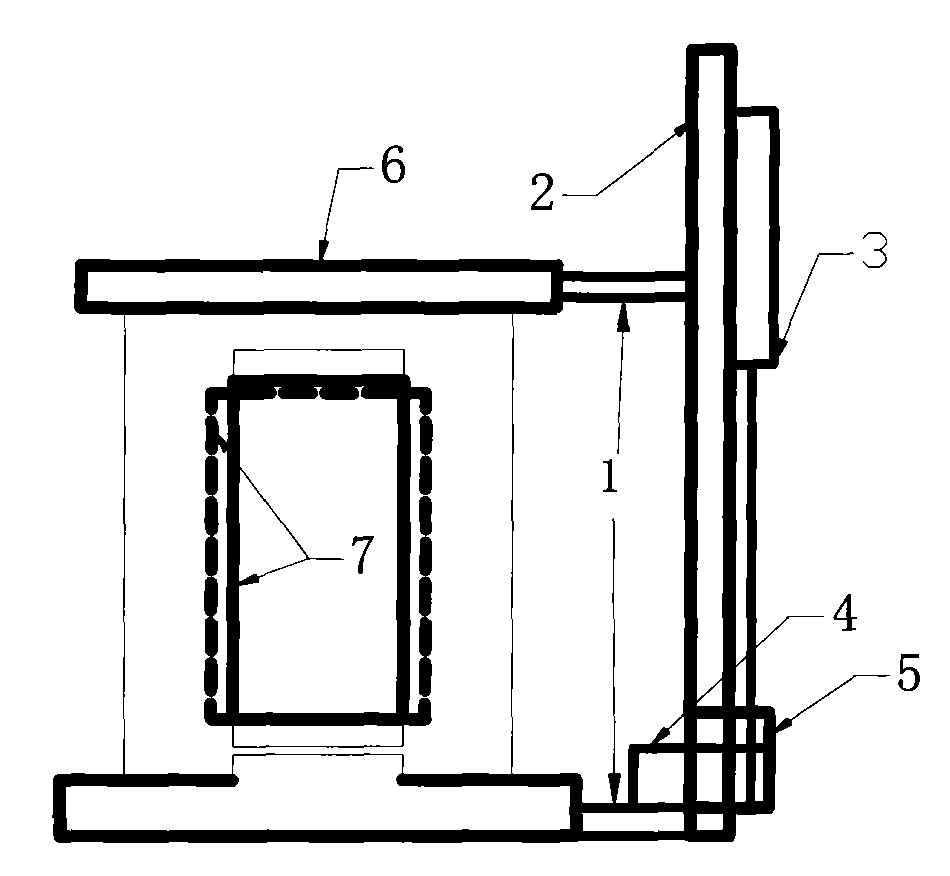

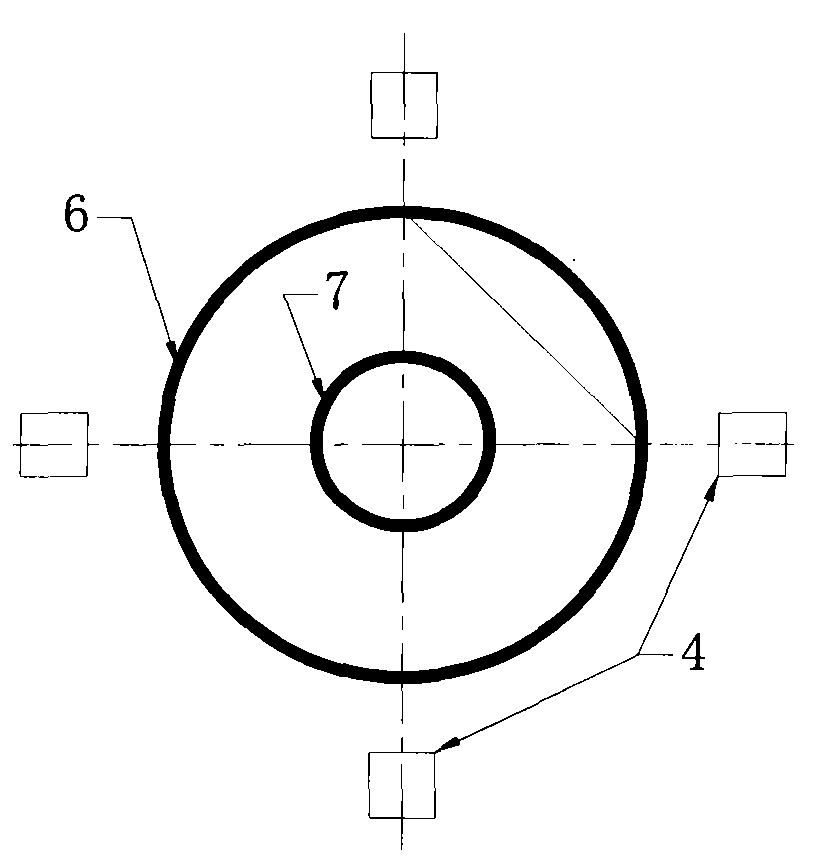

[0011] The measuring device mainly includes a positioning bracket 1 for sensor positioning, a fixed bracket 2 for installing and fixing the sensor, a displacement sensor 3, a laser range finder 4 and a data acquisition system. The positioning bracket 1 is fixed with the fixed bracket without rotation and relative displacement. The slider 5 on the fixed bracket is fixed with the lower end of the displacement sensor 3 and the laser rangefinder 4 to form a linkage device. The laser rangefinder and the displacement sensor The signal enters the data acquisition system and records the data in real time. The central axes of the fixed bracket 2, the displacement gauge 3, the laser range finder 4 and the slider 5 are parallel. During the measurement process, the up and down movement of the slider 5 drives the laser range finder 4 to move up and down, and the distance from the laser range finder 4 to the sample 7 is measured by the laser range finder 4 , and the measurement height is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com