Water-based lubricant composition for ceramic friction pair

A water-based lubricant and composition technology, applied in the field of lubrication, can solve the problems of high wear rate, achieve strong bearing capacity, high anti-wear performance, and prolong the life of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below through specific examples. It should be noted that the examples are only illustrative, and do not limit the protection scope of the present invention in any way.

[0023] 1. Preparation of water-based lubricant composition

[0024] A lubricant composition with a total weight of 1000 grams was prepared at room temperature as follows:

[0025] According to each component listed in Table 1 and component content, first weigh the alcohol amine of required weight, it is poured into the beaker that capacity is 1500 milliliters, then add the deionized water of required weight successively, and It is placed on a magnetic stirrer with a power of 350 watts, and nano-scale silicon dioxide, magnesium compound, phytate, and nano-scale graphite particles are added while stirring until the mixture is evenly stirred to obtain a lubricant composition, Examples 1-6 Each component and its content are shown in Table 1, wherein the "ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

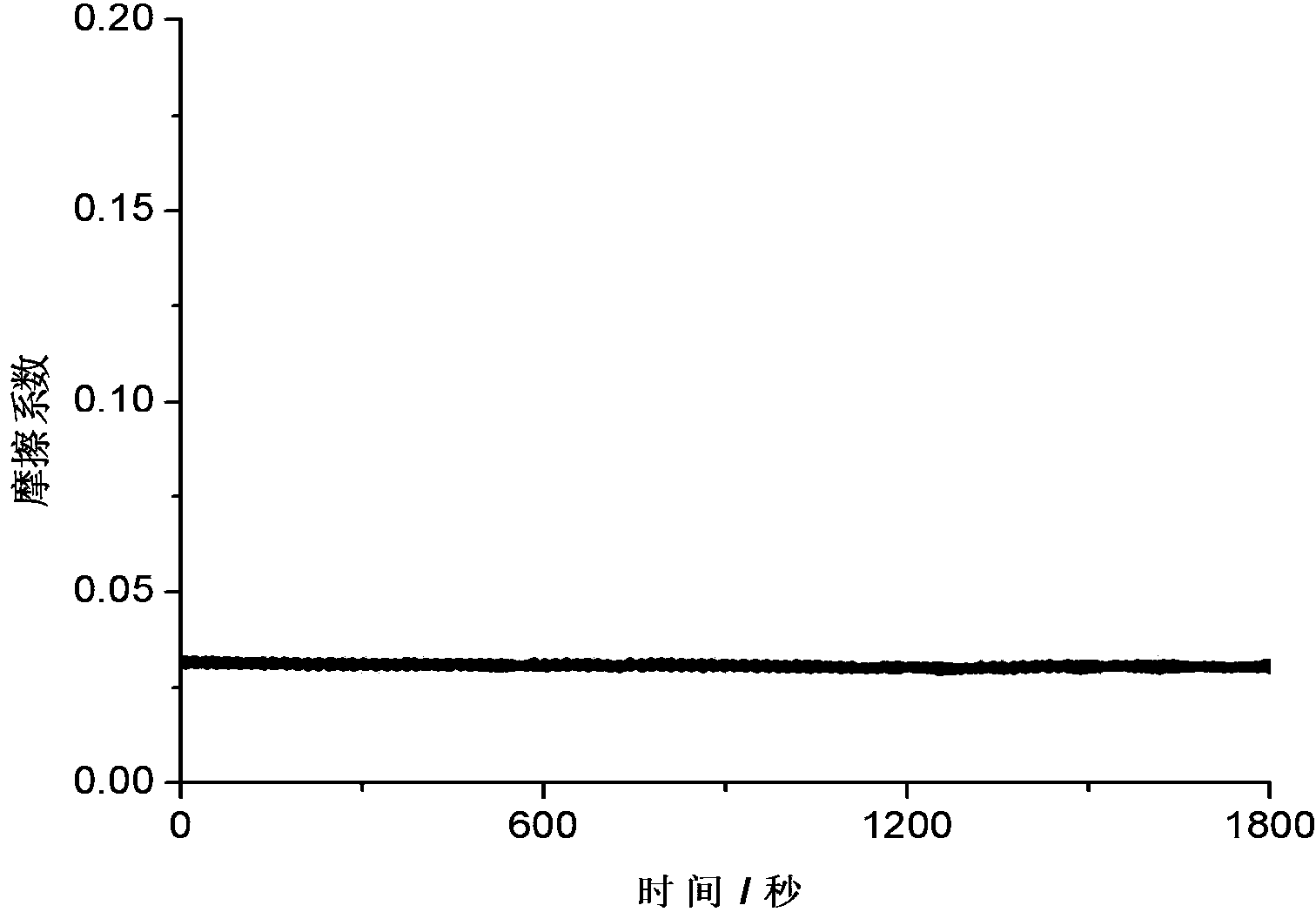

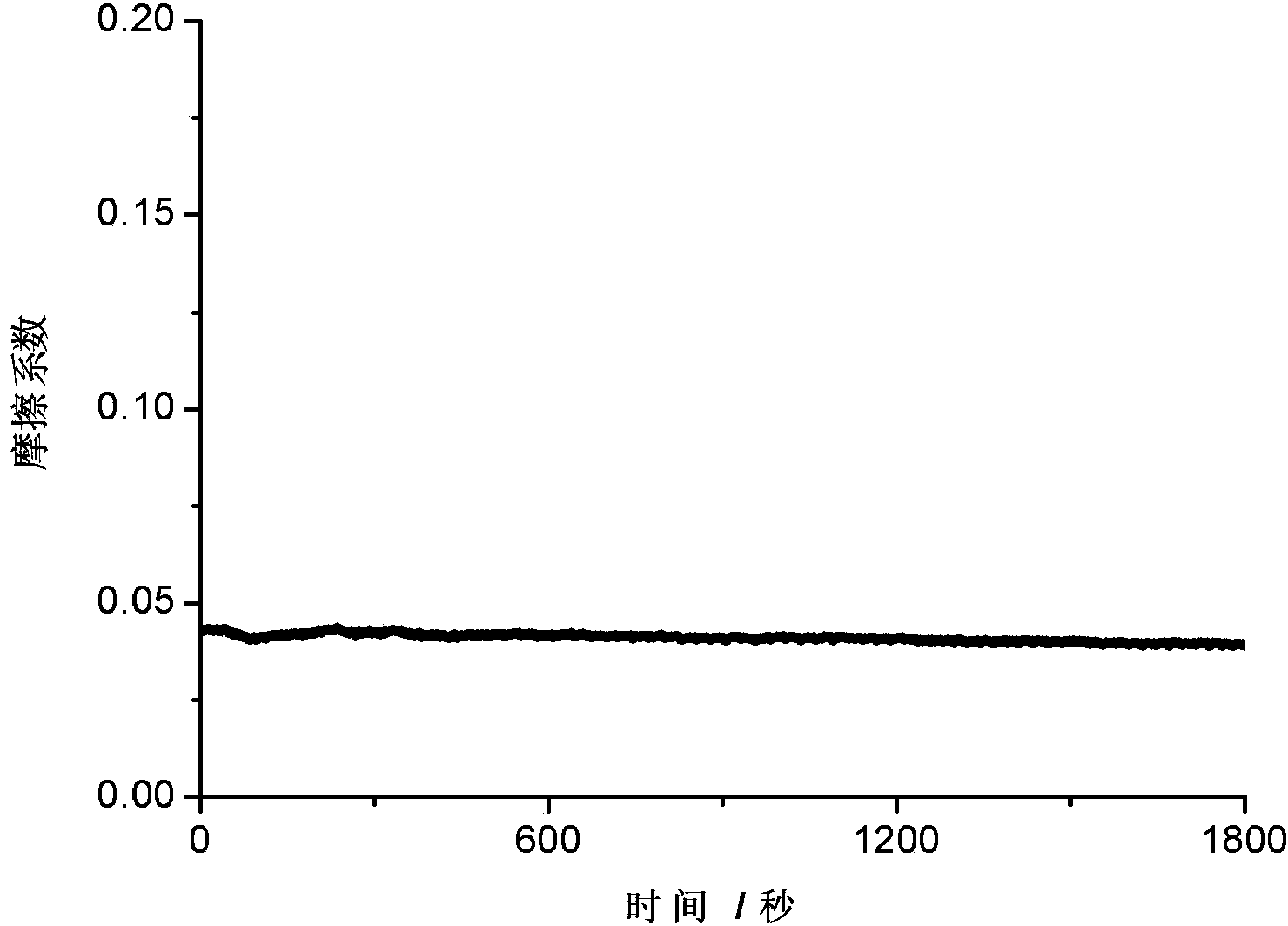

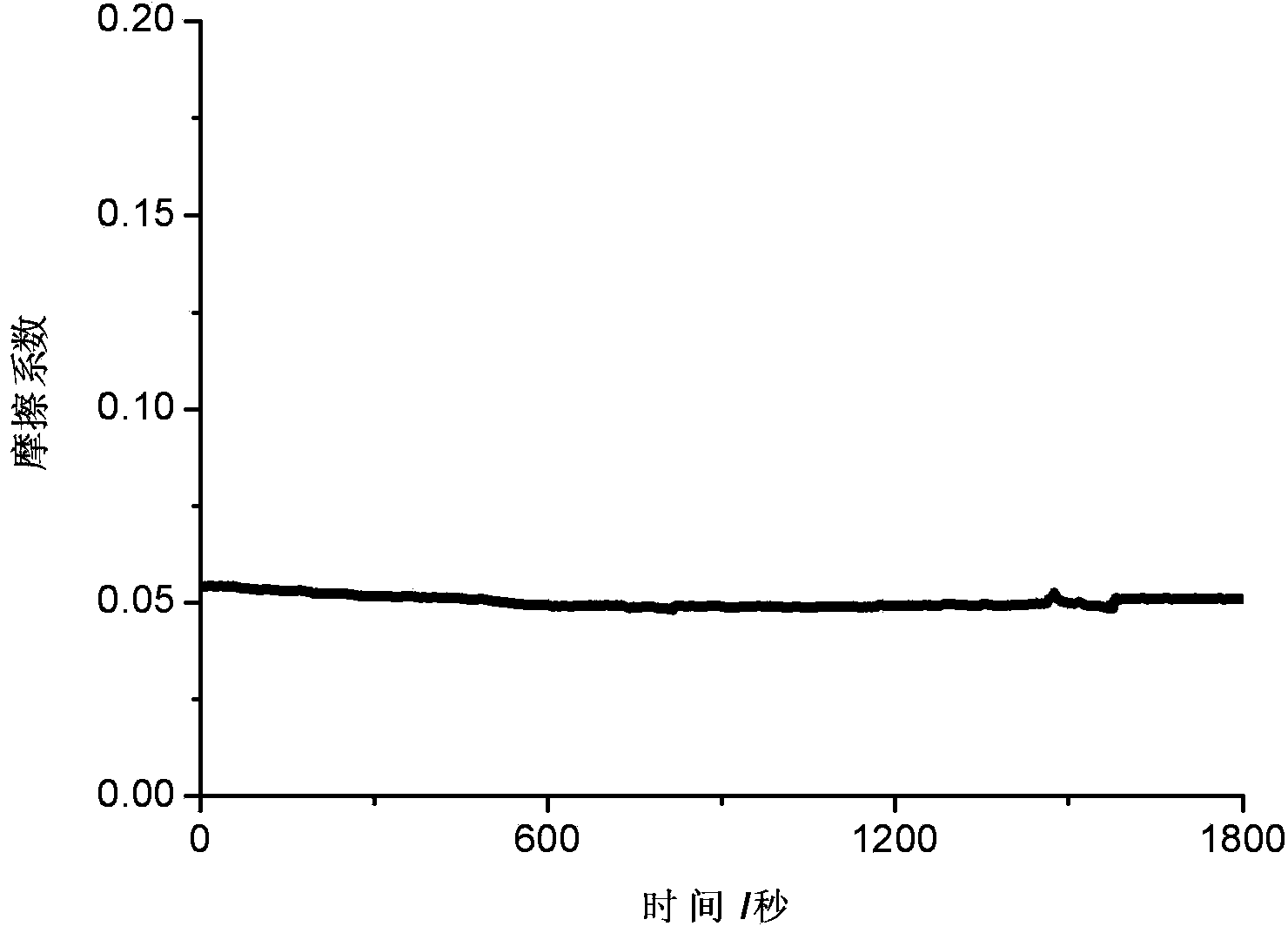

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com