Electro-polymeric organic fluorescent material and application of material in TNT detection

A fluorescent material and electropolymerization technology, applied in the field of fluorescent sensing, can solve problems such as material waste, and achieve the effect of clear structure, easy control, and stable mesh film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Embodiment 1: the synthesis of compound TCPC:

[0077]

[0078]

[0079] 2,7-Dibromofluorene

[0080] 6g (36mmol) of fluorene, 92mg (1.6mmol) of ferric chloride, and 4ml of liquid bromine were reacted in dichloromethane solvent for 12 hours in the dark. The resulting solid was filtered and recrystallized from ethanol to obtain a white solid product with a yield of 75%. 1 H NMR (500MHz, CDCl 3 ): δ7.66(s, 2H, Ar-H), δ7.60-7.59(d, 2H, Ar-H), δ7.51-7.49(d, 2H, Ar-H), δ3.87(s , 2H, Ar-H-Ar) Mass Spectrum (m / z) 323.9 Elemental Analysis: Calculated Value: C 13 h 8 Br 2 : C, 48.19; H, 2.49 Test value: C, 48.54; H, 2.51

[0081] 2,7-Dibromo-9-fluorenone

[0082] A methanol solution of 1.3g (4mmol) 2,7-dibromofluorene and 0.1ml tetrabutylhydroxylamine was vigorously stirred in a pyridine solvent, and oxygen was introduced at the same time. After a large amount of solid was produced, a large amount of water was injected, and a yellow solid product was obtained by fil...

Embodiment 2

[0095] Embodiment 2: the synthesis of compound OCPC:

[0096]

[0097] 9, 9, 9", 9"-bis(N-carbazol-hexyl)-9', 9', 9", 9"-biphenyl dibromofluorene

[0098] Take 2.0 grams of borofat, 3.12 grams of dibromine, 9 milliliters of anhydrous toluene, 219 milligrams of tetraphenylphosphopalladium, and 6 milligrams of sodium carbonate aqueous solution, and react at 90 degrees for two days. Petroleum ether dichloride (1:1) developing solvent column chromatography separation. Obtain product 2.18 grams, yield 61%

[0099] 1 H NMR (500MHz, CDCl3, 25°C, TMS): δ=8.04(d, J=7.6Hz, 8H; Ar-H), 7.70(m, 3H; Ar-H), 7.57(m, 5H; Ar -H), 7.45(m, 1H; Ar-H), 7.37(m, 10H; Ar-H), 7.24(m, 10H; Ar-H), 7.17(t, J=7.6Hz, 8H; Ar- H), 4.10(m, 8H; CH 2 ), 1.90(m, 8H; CH2), 1.63(m, 8H; CH 2 ), 1.07(m, 16H; CH 2 ), 0.60ppm (m, 8H; CH 2 ); 13C NMR (125MHz, CDCl 3 , 25°C, TMS): mass spectrum: 1406[M+]; elemental analysis theoretical value: C 98 h 93 BrN 4 : C, 83.67; H, 6.66; N, 3.98; test value: C, 83....

Embodiment 3

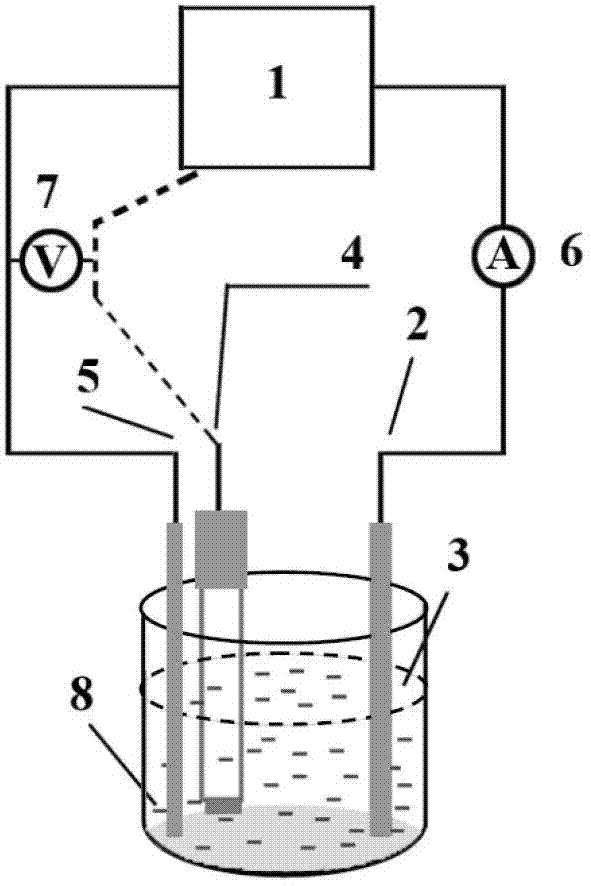

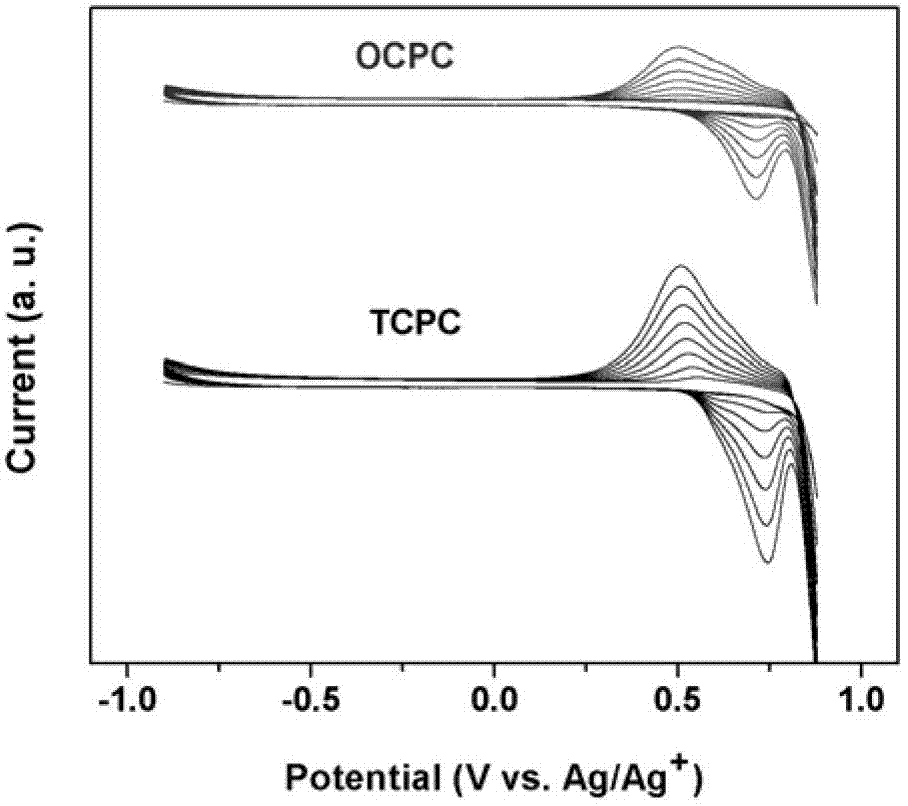

[0106] Embodiment 3: the preparation of electropolymerization film

[0107] The electropolymerization film was prepared by cyclic voltammetry, using tetra-n-butylammonium hexafluorophosphate TPAPF6 as the electrolyte, the concentration of TCPC or OCPC was 0.5mg / ml, and the mixed solution of dichloroacetonitrile (volume ratio 2:3) Accompanied by the dedoping process of each layer of electrochemically polymerized film. We chose 0.89 V as the upper limit of the scan range for cyclic voltammetry settings. In order to improve the dedoping performance of the electrochemically polymerized film, we set the lower limit of the cyclic voltammetry scanning range to be -0.9V, and then set the cyclic voltammetry scanning range to be -0.9V~0.89V. Set the scanning speed to 200mV / s, and the number of scanning cycles to 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com