Polymer dispersed liquid crystal film and preparation method thereof

A technology for dispersing liquid crystals and polymers, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of difficult to effectively control the driving voltage and contrast, and the inability to effectively control the structure and molecular weight of the polymer matrix, and achieve high-efficiency room temperature activity. Free radical polymerization, avoid UV damage to human body, improve the effect of open light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

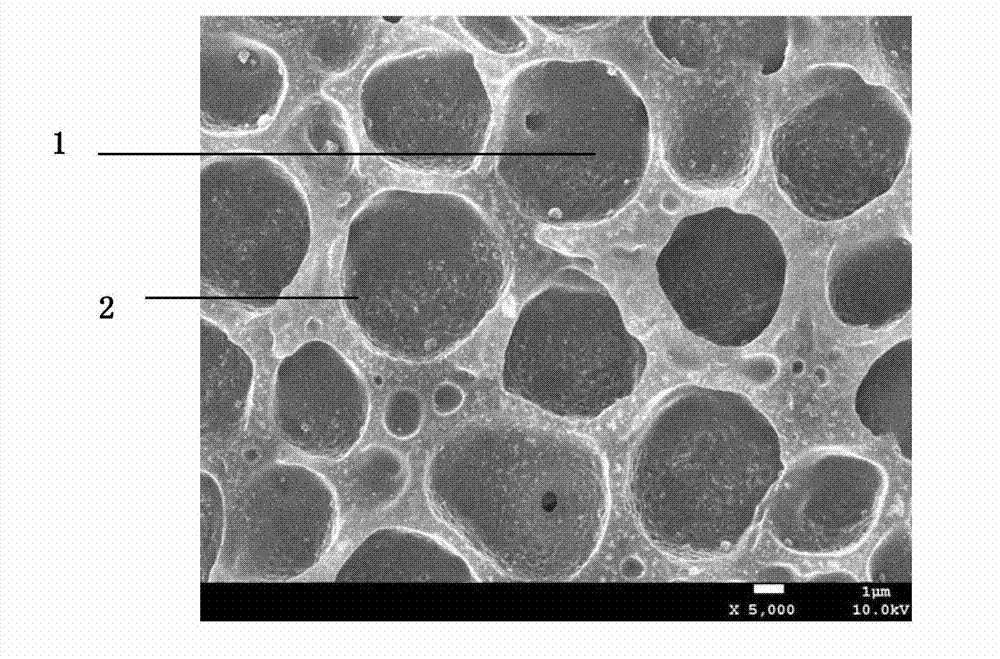

Image

Examples

Embodiment 1

[0024] a. Mix 15 parts of 4-methoxystyrene (MOSt), 0.023 parts of azobisisobutyronitrile (Tianjin Damao Chemical Reagent Factory, analytically pure), 0.225 parts of S, S'-di(α,α'- Dimethyl-α''-acetic acid)-trithiocarbonate [self-made in the laboratory, the steps are as follows: install mechanical stirring on a four-necked round-bottomed flask adding 1.4 g of tetradecyltrimethylammonium bromide, condensing tube, thermometer and constant pressure funnel, add carbon disulfide (15.6 g, 0.20 mol), acetone (29.0 g, 0.50 mol), chloroform (53.8 g, 0.45 mol) and petroleum ether (60 mL) after deoxygenation, and cool in an ice-water bath. Nitrogen gas was passed through the mixture for 15 min, and 50% sodium hydroxide solution (101.0 g, 1.26 mol) pre-cooled to about 10 °C was added dropwise, and the reaction temperature was maintained at 15-20 °C and stirred overnight. Pour the orange-red slurry reaction mixture into a flask filled with 400 mL of distilled water, separate the water phase...

Embodiment 2

[0029] Embodiment 2 Molecular weight of macromolecular reagent

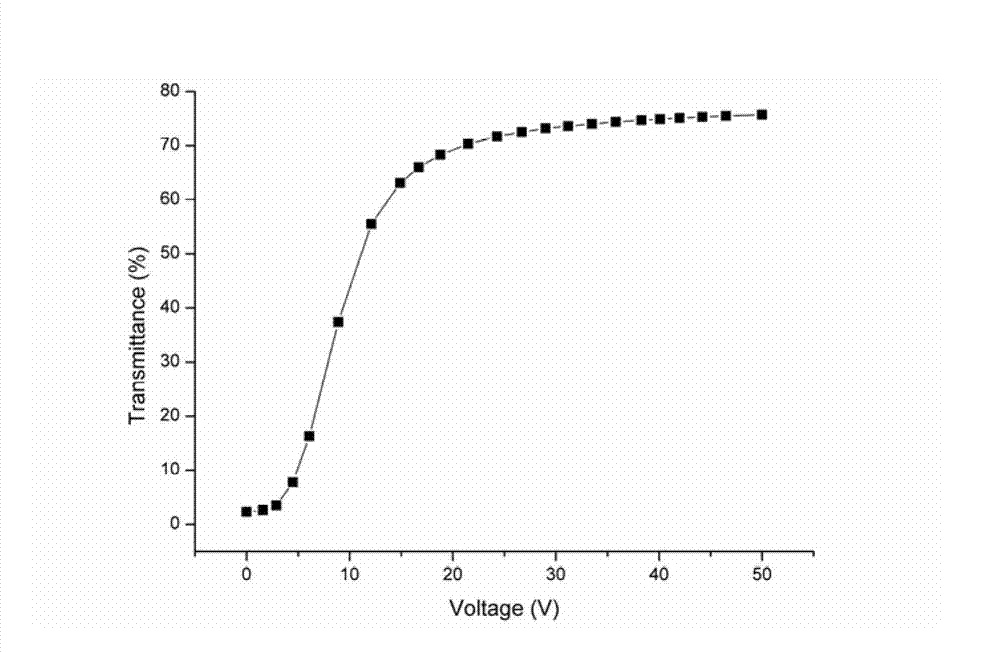

[0030] According to the method in Example 1, the macromolecular reagent RAFT-PMOSt was synthesized and a PDLC film was fabricated. The preparation ratio and photocuring process of the photosensitive solution are the same as in Example 1, except that the formula for synthesizing the macromolecular reagent RAFT-PMOST is: 15 parts of 4-methoxystyrene, 0.034 parts of azobisisobutyronitrile, S, S'- 0.26 parts of bis(α,α'-dimethyl-α''-acetic acid)-trithiocarbonate and 10 ml of tetrahydrofuran. The number average molecular weight of the polymer matrix measured by GPC was 46500, and the molecular weight distribution was 1.32. In this embodiment, the driving voltage is 16V, and the light transmittance in the open state is 68.3%.

Embodiment 3

[0032] According to the method in Example 1, macromolecular reagents were synthesized and PDLC membranes were fabricated. The preparation ratio and photocuring process of the photosensitive solution are the same as in Example 1, except that the formula for synthesizing macromolecular reagents is: 15 parts of 4-trifluoromethylstyrene (TFSt), 0.025 parts of azobisisobutyronitrile, S, S' - 0.21 part of bis(α,α'-dimethyl-α''-acetic acid)-trithiocarbonate and 10 ml of tetrahydrofuran, the prepared macromolecular reagent is RAFT-PTFSt. The number average molecular weight of the polymer matrix measured by GPC was 57400, and the molecular weight distribution was 1.33. In this embodiment, the driving voltage is 18V, and the light transmittance in the open state is 69.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com