A kind of preparation method of pdlc film based on liquid crystal/polymer composite material system

A technology of composite materials and liquid crystal materials, which is applied in the field of UV curing system of crystal/polymer composite materials, can solve the problems of reducing the brightness and contrast of display devices, so as to reduce the anchoring effect, increase the contrast ratio and reduce the driving voltage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

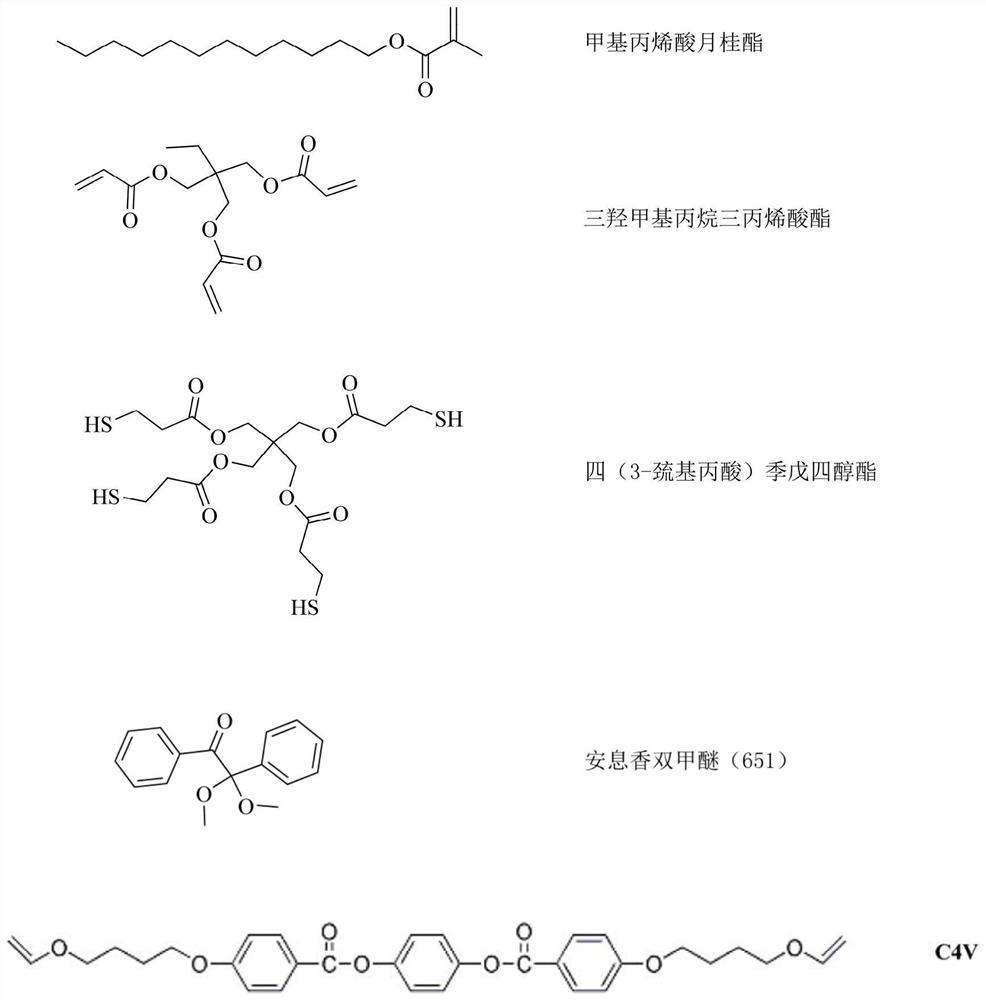

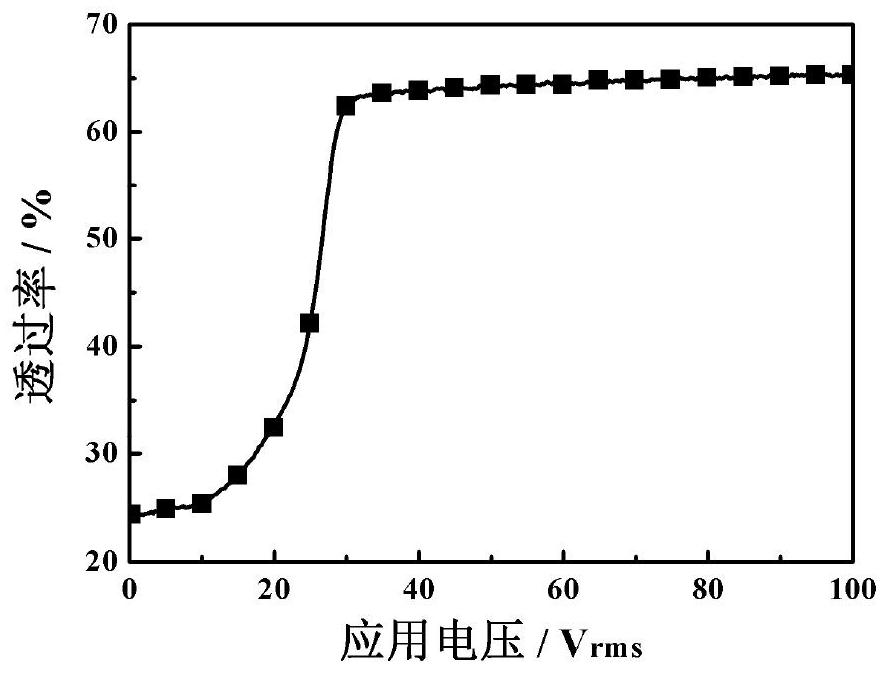

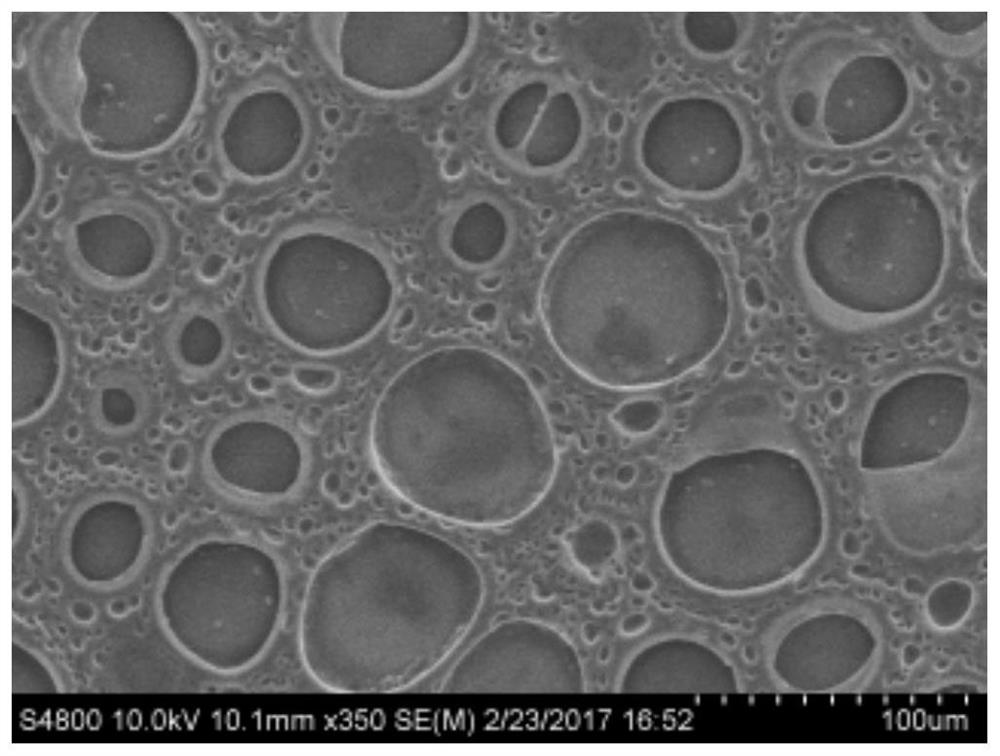

[0034]The photopolymerizable monomers selected were lauryl methacrylate, trimethylolpropane triacrylate and pentaerythritol tetrakis(3-mercaptopropionate). Mix the polymerizable monomer with the nematic liquid crystal SLC1717 at a mass ratio of 35.0:65.0. The mass ratio of lauryl methacrylate, trimethylolpropane triacrylate, pentaerythritol tetrakis(3-mercaptopropionate) and vinyl ether is 24.0:6.0:2.0:3.0. The mass of the photoinitiator benzoin dimethyl ether (651) is 3.0% of the total mass of the photopolymerizable monomers. After stirring evenly, the mixture is in a clear state at room temperature, and the mixture is poured into a liquid crystal cell with a cell thickness of 20 μm by the principle of siphon, and then heated at room temperature with a light intensity of 2mw / cm 2 , irradiate with ultraviolet light with a wavelength of 365nm for 5 minutes, then carry out two-step polymerization at room temperature with an electric field intensity of 100V and an electric field...

Embodiment 2

[0038] The photopolymerizable monomers selected were lauryl methacrylate, trimethylolpropane triacrylate, pentaerythritol tetrakis(3-mercaptopropionate), and vinyl ether. Mix the polymerizable monomer with the nematic liquid crystal SLC1717 at a mass ratio of 35.0:65.0. The mass ratio of lauryl methacrylate, trimethylolpropane triacrylate, pentaerythritol tetrakis(3-mercaptopropionate) and vinyl ether is 20.0:10.0:2.0:3.0. The mass of the photoinitiator benzoin dimethyl ether (651) is 3.0% of the total mass of the photopolymerizable monomers. After stirring evenly, the mixture is in a clear state at room temperature, and the mixture is poured into a liquid crystal cell with a cell thickness of 20 μm by the principle of siphon, and then heated at room temperature with a light intensity of 2mw / cm 2 , irradiated with ultraviolet light with a wavelength of 365nm for 8 minutes, and then at room temperature, the electric field intensity is 100V, and the electric field frequency is ...

Embodiment 3

[0042] The photopolymerizable monomers selected were lauryl methacrylate, trimethylolpropane triacrylate, pentaerythritol tetrakis(3-mercaptopropionate), and vinyl ether. Mix the polymerizable monomer with the nematic liquid crystal SLC1717 at a mass ratio of 35.0:65.0. The mass ratio of lauryl methacrylate, trimethylolpropane triacrylate, pentaerythritol tetrakis(3-mercaptopropionate) and vinyl ether is 23.0:5.0:2.0:5.0. The mass of the photoinitiator benzoin dimethyl ether (651) is 3.0% of the total mass of the photopolymerizable monomers. After stirring evenly, the mixture is in a clear state at room temperature, and the mixture is poured into a liquid crystal cell with a cell thickness of 20 μm by the principle of siphon, and then heated at room temperature with a light intensity of 2mw / cm 2 , irradiate with ultraviolet light with a wavelength of 365nm for 5 minutes, then carry out two-step polymerization at room temperature with an electric field intensity of 100V and an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com