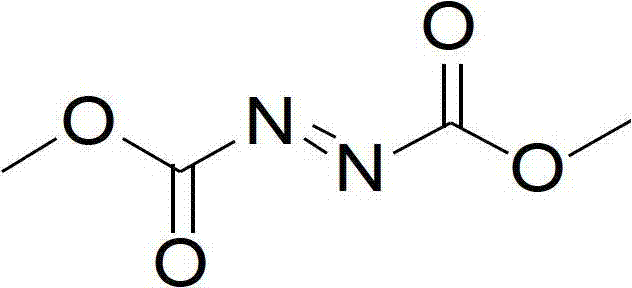

Synthesis method for dimethyl azodicarboxylate and intermediate thereof

A technology of dimethyl azodicarboxylate and dimethyl hydrogen azodicarboxylate is applied in the preparation of hydrazide, organic chemistry, etc., can solve problems such as environmental pollution, and achieves good economy, high yield and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In a 500ml three-necked flask equipped with mechanical stirring, 250ml of dimethyl carbonate was added, and 125g of hydrazine hydrate with a mass percentage of 80% was added. The mixture was heated to reflux in an oil bath for 5 hours, and the excess dimethyl carbonate was evaporated. After the remaining mixed solution was spin-dried under reduced pressure, the crude methyl carbazate was obtained. Recrystallization with acetone gave 171 g (95.0%) of white transparent crystals, mp=69-72°C.

[0043] II, the preparation of dimethyl hydrogen azodicarboxylate

Embodiment 2

[0045] In a 250ml three-necked flask equipped with mechanical stirring, add 120ml of anhydrous methanol, add 6.9g of sodium metal under nitrogen protection, after the sodium metal is completely dissolved, add 27g of methyl carbazate, and after 0.5h, the solution turns orange red . Slowly add 30 g of dimethyl carbonate dropwise, and after the dropwise addition, react at room temperature for 6 hours to obtain a light yellow turbid liquid, and recover methanol and dimethyl carbonate by atmospheric distillation. Adjust pH≈6.0 with 10% hydrochloric acid solution, white crystals are precipitated, washed with cold water to obtain a crude product of dimethyl hydrogen azodicarboxylate, and the above crude product is successively recrystallized with acetone and petroleum ether to obtain a white solid hydrogen azo Dimethyl diformate 5.4g (12.2%) mp=131-133℃.

[0046] 1 HNMR (CDCl 3 ,300MHz)δ:9.06(2H,s,NH);3.58(6H,s,CH 3 ).

Embodiment 3

[0048]In a 250ml three-necked flask equipped with mechanical stirring, add 120ml of anhydrous methanol, add 6.9g of sodium metal under nitrogen protection, after the sodium metal is completely dissolved, add 27g of methyl carbazate, and after 0.5h, the solution turns orange red . Slowly add 30 g of dimethyl carbonate dropwise, and react at 65° C. for 6 h after the dropwise addition to obtain a light yellow turbid liquid. Methanol and dimethyl carbonate are recovered by atmospheric distillation. Adjust pH≈6.0 with 10% hydrochloric acid solution, white crystals are precipitated, washed with cold water to obtain a crude product of dimethyl hydrogen azodicarboxylate, and the above crude product is successively recrystallized with acetone and petroleum ether to obtain a white solid hydrogen azo Dimethyl diformate 36.7g (82.7%) mp=131-133℃.

[0049] 1 HNMR (CDCl 3 ,300MHz)δ:9.06(2H,s,NH);3.58(6H,s,CH 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com