Special compound additive for pebble-type permeable concrete

A permeable concrete and composite technology, applied in the field of building materials, can solve problems such as inconvenient concrete quality control, adverse effects on concrete performance, easy sinking of slurry, etc., achieve good technical and social benefits, facilitate concrete quality control, increase The effect of encapsulation and cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

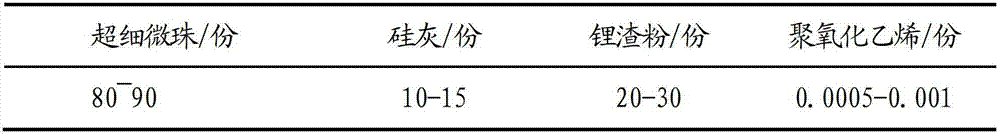

[0050] The special compound additive for pebble-type permeable concrete includes ultrafine beads, silica fume, lithium slag powder, polyethylene oxide, and the mass parts of each raw material are: 80 parts of ultrafine beads, 11 parts of silica fume, and lithium slag 20 parts of powder and 0.001 parts of polyethylene oxide.

Embodiment 6

[0052] The special compound additive for pebble-type permeable concrete includes ultrafine beads, silica fume, lithium slag powder, polyethylene oxide, and the mass parts of each raw material are: 85 parts of ultrafine beads, 13 parts of silica fume, and lithium slag 18 parts of powder and 0.001 parts of polyethylene oxide.

Embodiment 7

[0054] The special compound additive for pebble-type permeable concrete includes ultrafine beads, silica fume, lithium slag powder, polyethylene oxide, and the mass parts of each raw material are: 86 parts of ultrafine beads, 15 parts of silica fume, and lithium slag 25 parts of powder and 0.0009 parts of polyethylene oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com