Method for activating high-sulfur bauxite by means of low-temperature roasting desulfurization method

A technology of high-sulfur bauxite and bauxite, applied in chemical instruments and methods, separation methods, preparation of alkali metal aluminate/alumina/aluminum hydroxide, etc., can solve energy waste, gas-liquid mass transfer efficiency Poor, high roasting desulfurization temperature and other problems, to achieve the effect of reducing energy consumption and heat source cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

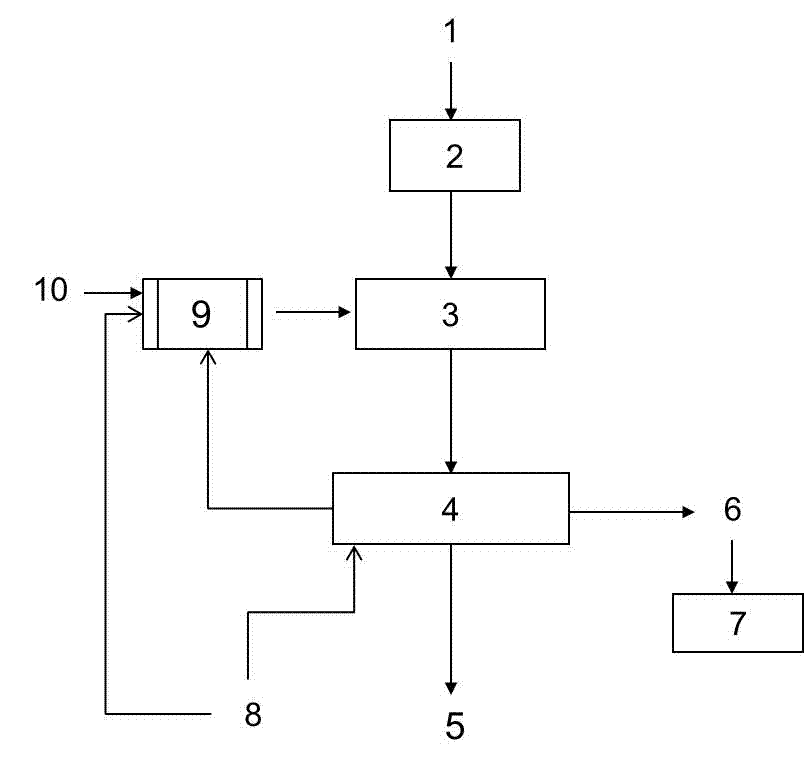

Method used

Image

Examples

Embodiment 1

[0039] Example 1 Oxidative Roasting Desulfurization and Activation of High-sulfur Bauxite Powder Fluidized Furnace and Limestone Wet Purification of Roasting Tail Gas

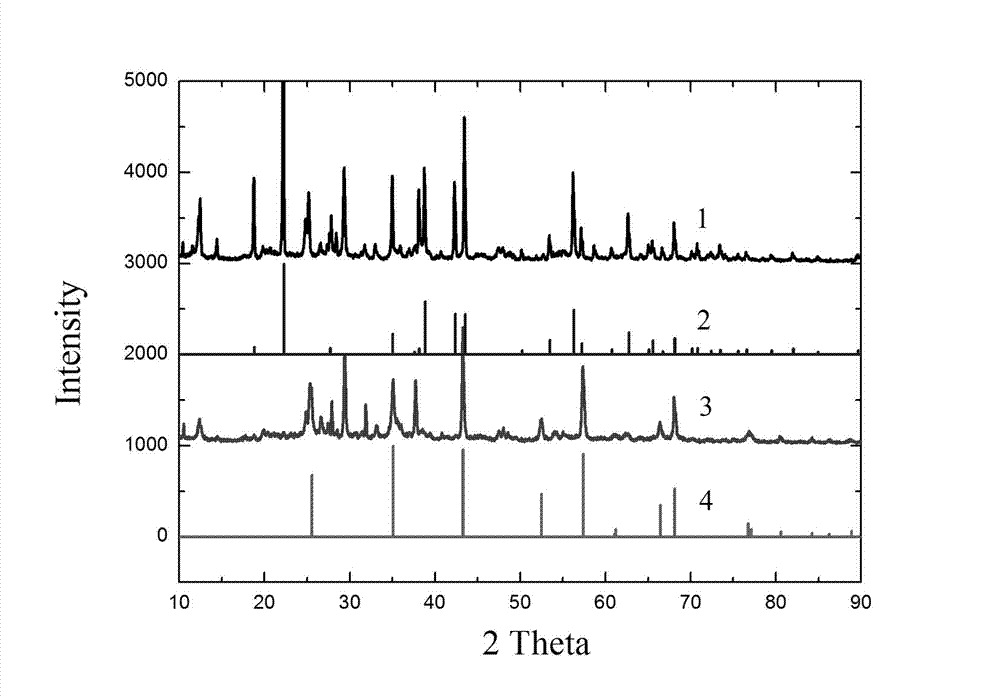

[0040] Dry and grind the high-sulfur bauxite with an aluminum-silicon ratio of 7.1 and a sulfur content of 3.7%, and pass through 50 meshes to take the ore powder with a particle size of 2 , make the ore powder in the temperature range of 560~600°C for fluidized oxidative desulfurization and dehydration transformation activation, keep it in the fluidized bed furnace for 5~10 minutes, and the sulfur content of the ore powder will drop to 0.43% after roasting; press the roasted desulfurization ore powder With a sodium-aluminum ratio of 1.6, add lime equivalent to 4% of the bauxite content, dissolve in a solution with a caustic concentration of 240g / L at 240°C for 60 minutes, and the dissolution rate of alumina is 93.4%; use cold air The roasting desulfurization tail gas is cooled by a heat exchanger, the temperatu...

Embodiment 2

[0041] Example 2 Oxidative roasting desulfurization and activation of high-sulfur bauxite powder rotary kiln and purification of roasting tail gas by red mud method

[0042] Dry and grind the high-sulfur bauxite with an aluminum-silicon ratio of 8.1 and a sulfur content of 4.1%, and pass through 20 meshes to obtain ore powder with a particle size of 2 , make the ore powder in the temperature range of 500~535°C for fluidized oxidative desulfurization and dehydration transformation activation, keep it in the rotary kiln for 30~40 minutes, and the sulfur content of the ore powder will be reduced to 0.31% after roasting; the roasted desulfurization ore powder According to the sodium-aluminum ratio of 1.45, add lime equivalent to 4% of the bauxite content, dissolve in the eluate with a caustic concentration of 200g / L at 220°C for 90 minutes, and the dissolution rate of alumina is 93.1%. The air passes through the heat exchanger to cool the roasting desulfurization tail gas, and the ...

Embodiment 3

[0043] Example 3 Oxidative roasting desulfurization and activation of high-sulfur bauxite powder fluidized furnace and purification of roasting tail gas by red mud method

[0044] Dry and grind the high-sulfur bauxite with an aluminum-silicon ratio of 6.5 and a sulfur content of 2.1%, and pass through 80 mesh and 200 mesh respectively to obtain mineral powder with a particle size of 0.075~0.18mm; The air is heated by hot air at 750~850°C; after the ore powder is added to the fluidized bed, the hot air is added from the lower side of the fluidized bed, and the FeS in the ore powder is heated and ignited in the fluidized bed by hot air. 2 , so that the ore powder is activated by fluidized oxidation desulfurization and dehydration within the temperature range of 540~580°C, and kept in the fluidized furnace for 10~15 minutes, and the sulfur content of the ore powder is reduced to 0.22% after roasting; the roasted desulfurization ore powder is pressed With a sodium-aluminum ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com