Sulfur forming device and working method

A molding device and sulfur technology, applied in the preparation/purification of sulfur, etc., can solve the problems of many sources of raw materials, large fluctuations in product quality, complex components, etc., to shorten the process flow, improve the stability and operability, Optimizing the effect of the recycling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

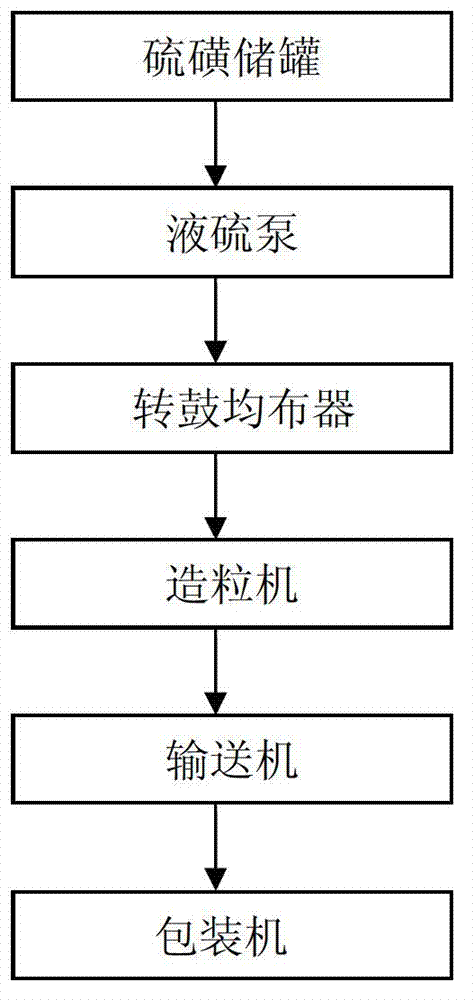

[0014] like figure 1 As shown, the specific embodiment of the present invention mainly includes the following steps: the liquid sulfur from the sulfur storage tank is transported to the rotary drum uniform distributor through the liquid sulfur pump, and the liquid is sprayed onto the steel belt of the granulator in the form of droplets, By adjusting the operating speed, the size and quality of the solid sulfur particles formed are controlled and adjusted. At the same time, a continuous spray water cooling device is installed under the steel belt to cool and solidify the material during the moving process, and finally transported to the packaging machine by the conveyor for finished product packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com