Film tearing machine and film tearing method

A film machine and film technology, applied in chemical instruments and methods, layered products, lamination auxiliary operations, etc., can solve the problems of increasing the cost of polarizer film tearing, the tape cannot be reused, etc., and achieve automatic film tearing action, Reduce the cost of tearing film and realize the effect of tearing film action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

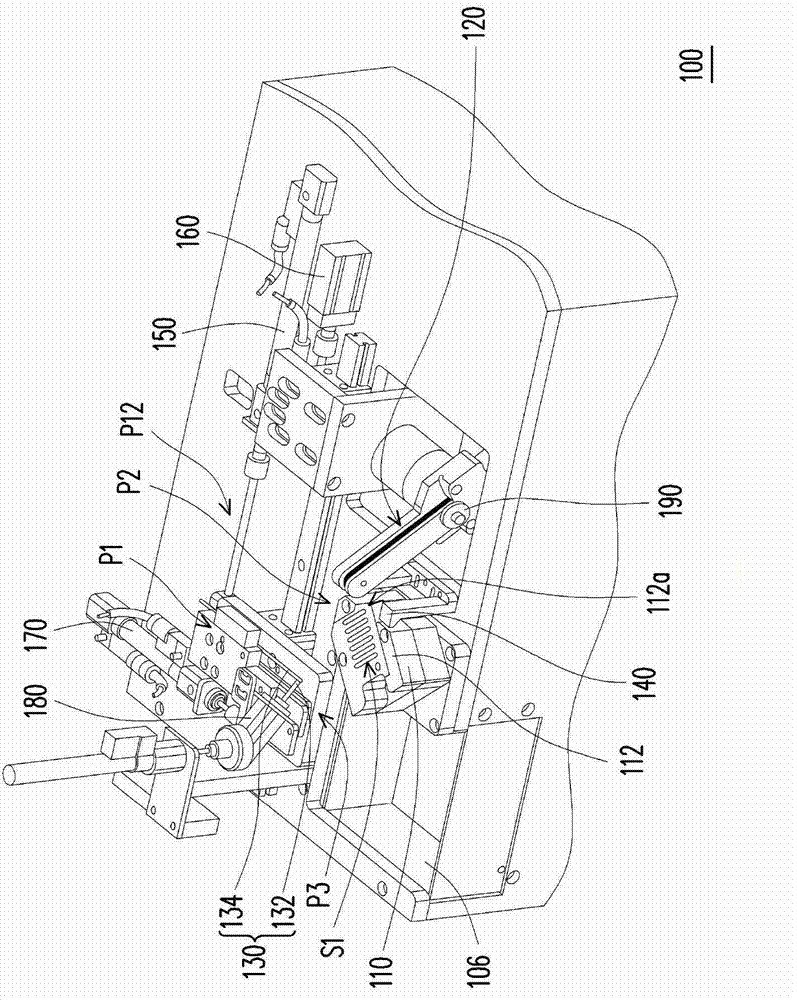

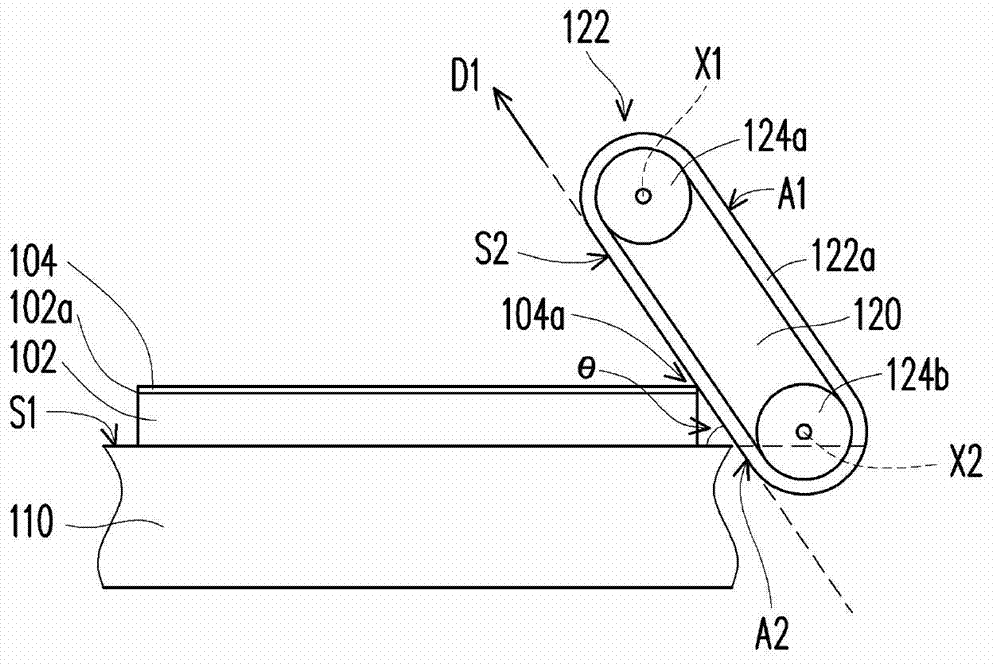

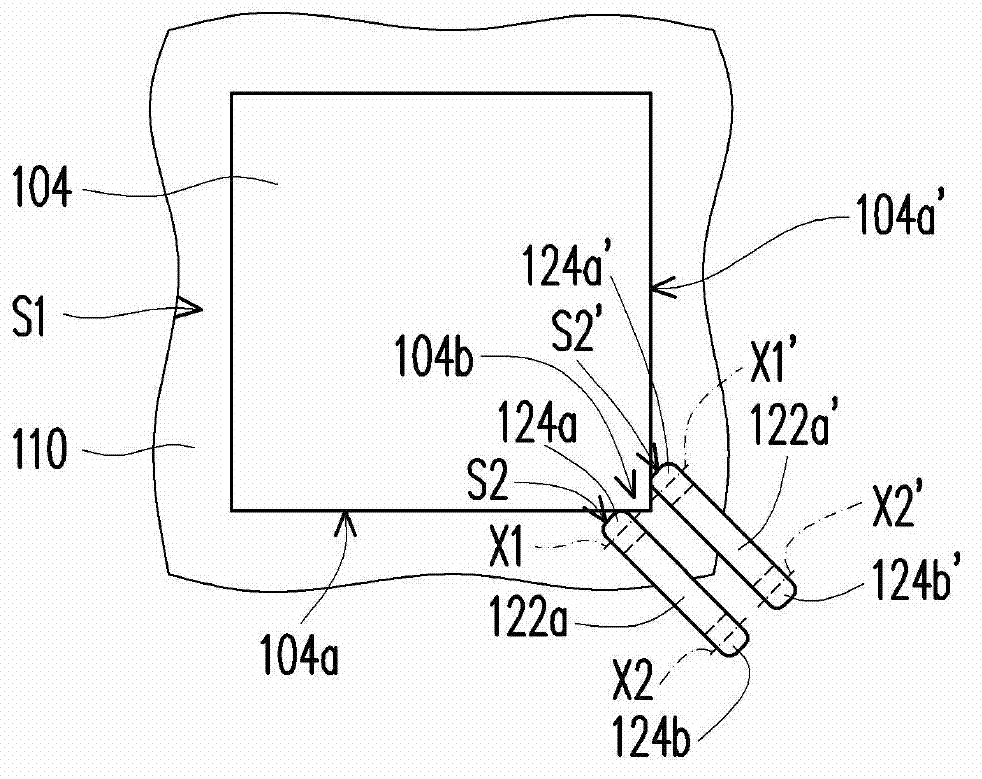

[0075] figure 1 It is a perspective view of a film tearing machine according to an embodiment of the present invention. figure 2 yes figure 1 Schematic diagram of the front view of the tearing device. Please refer to figure 1 and figure 2 , in this embodiment, the film tearing machine 100 includes a carrier 110 , a tearing device 120 and a gripper 130 , adapted to remove the film 104 on the surface 102 a of the substrate 102 . The carrier 110 has a carrying surface S1 for carrying the substrate 102 . In other words, the substrate 102 can be placed on the carrying surface S1 of the carrier 110 so that the film 104 on the surface 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com