Film tearing and removing module

A technology of modules and membrane components, which is applied in packaging, transportation and packaging, and unsealing of objects. It can solve the problems of workpiece appearance, easy to leave traces, and slow efficiency, so as to avoid human participation, reduce occupancy, and improve tearing. Effect of Membrane Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

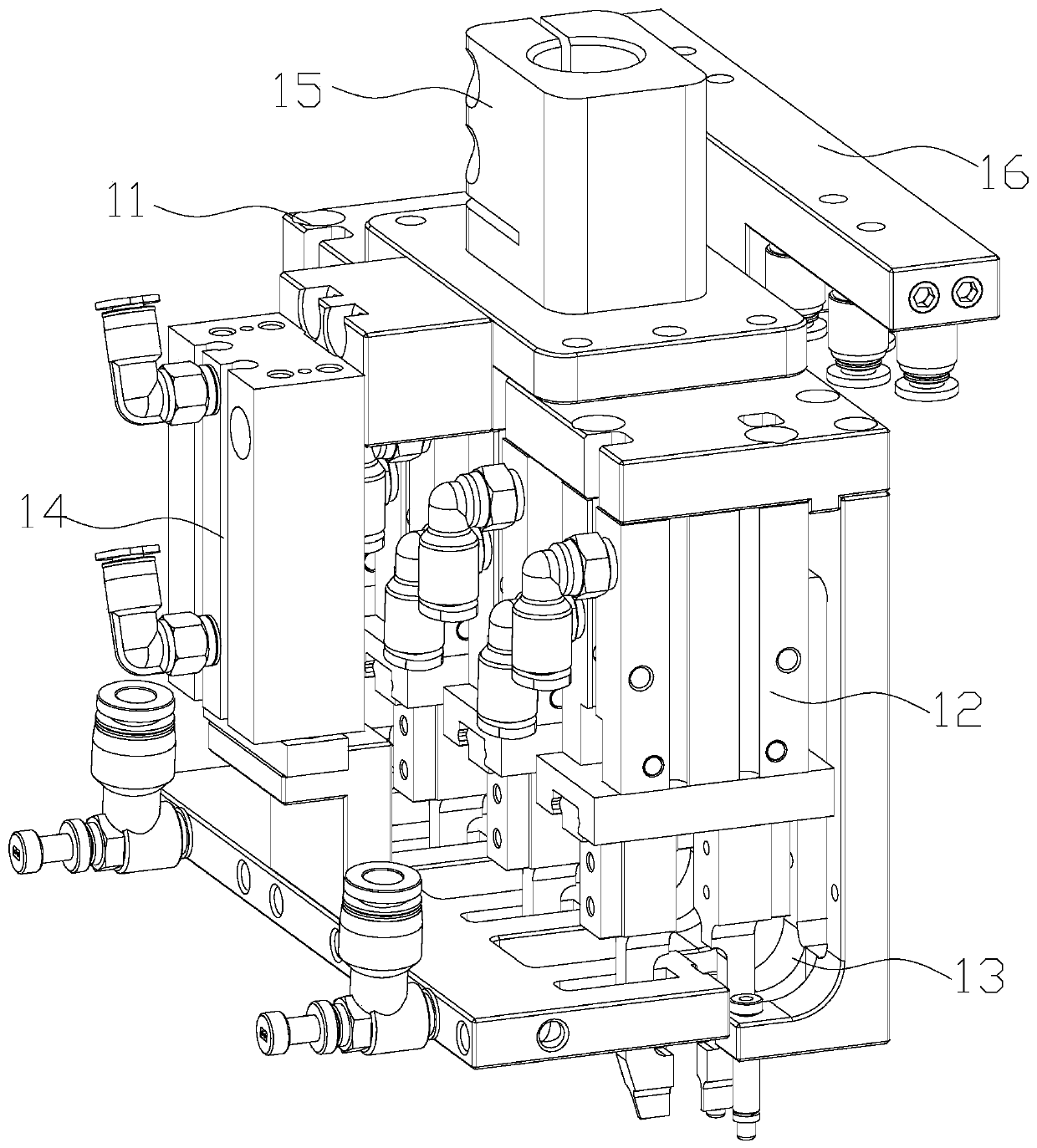

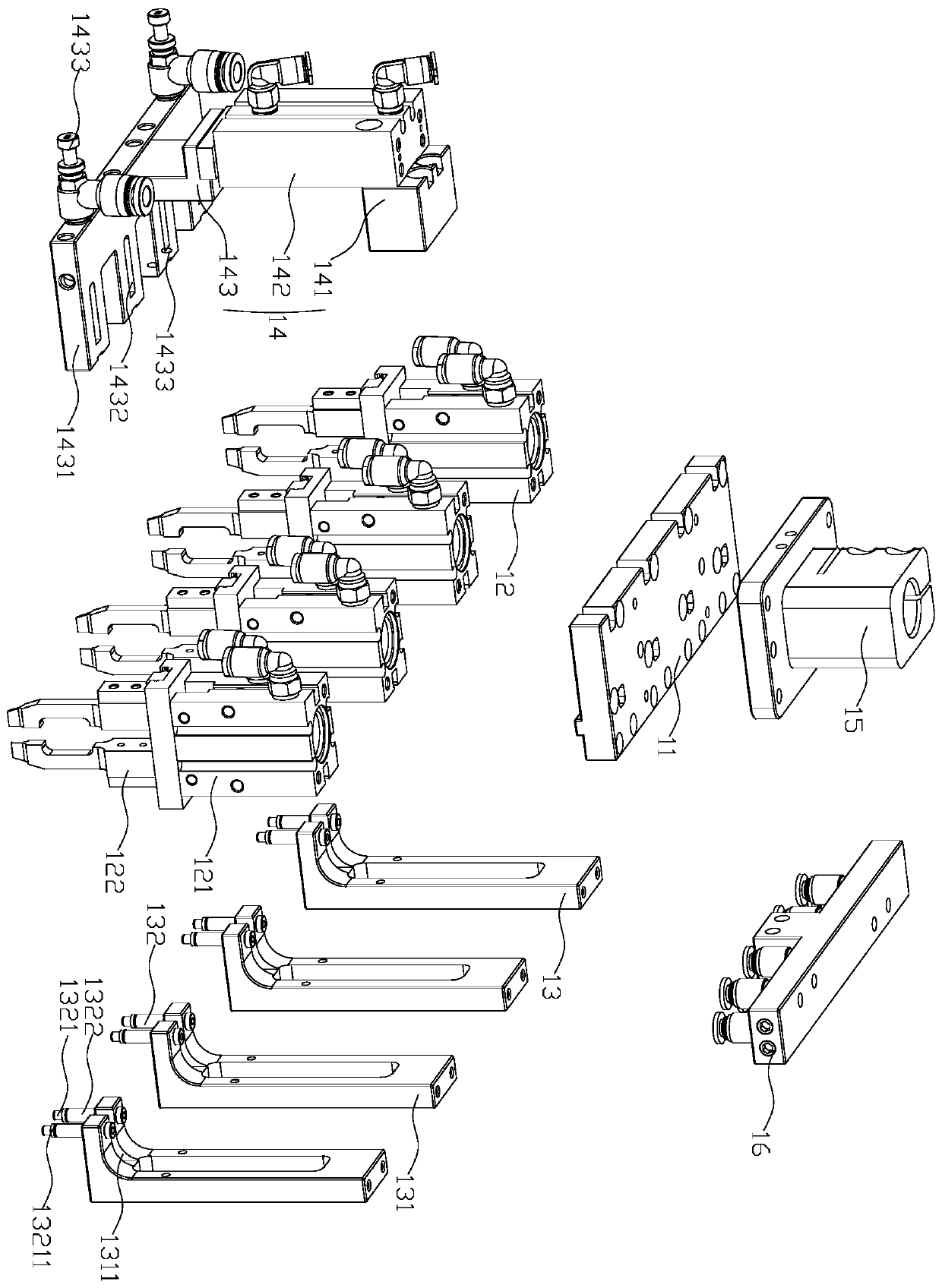

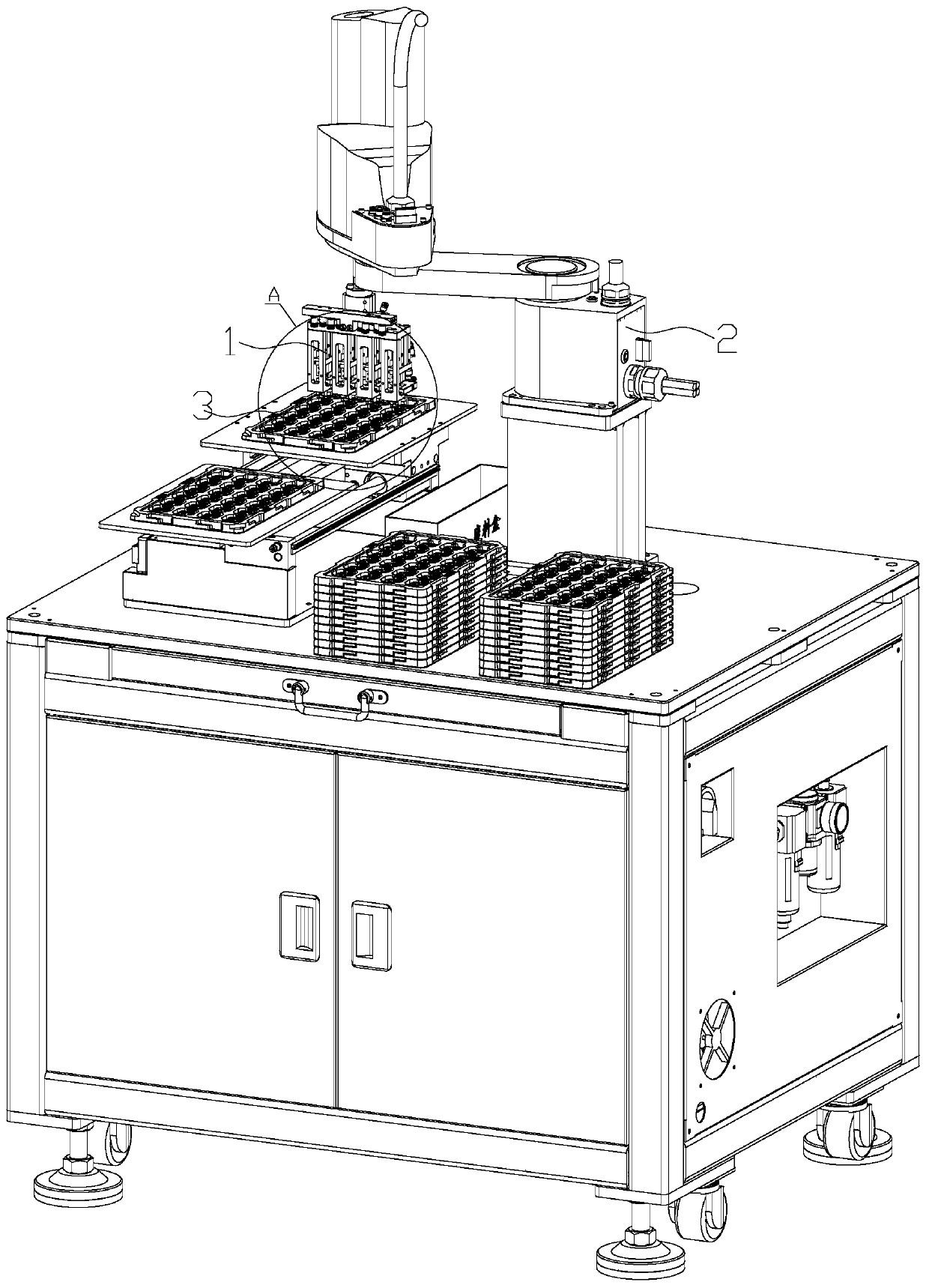

[0029] Figure 1-2 Schematically shows a tear film waste discharge module 1 according to an embodiment of the present invention, including a main mounting plate 11, several tear film assemblies 12, several top pressure assemblies 13 and a film release assembly 14, several tear film assemblies 12 Arrays are arranged on the lower end surface of the main mounting plate 11, and several pressing assemblies 13 are arranged in an array on the lower end surface of the main mounting plate 11. Several pressing assemblies 13 are respectively matched with a plurality of tearing film assemblies 12, and the release assembly 14 is arranged on the One side of the main mounting plate 11 is matched with the active ends of several film tearing assemblies 12, and several pressing assemblies 13 are oppositely distributed with the stripping assembly 14. The quantity of the tearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com