Sterilization system for filling equipment

A technology of sterilization system and filling equipment, applied in the direction of chemistry, etc., can solve the problems of large hydrogen peroxide residue and unsuitable containers for filling, so as to reduce the residual amount of sterilization medium, shorten the filling process and increase the sterilization effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

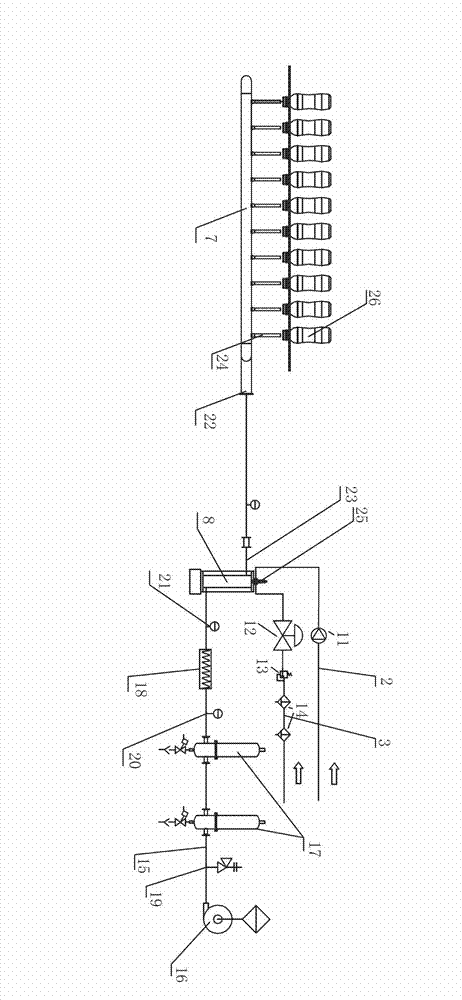

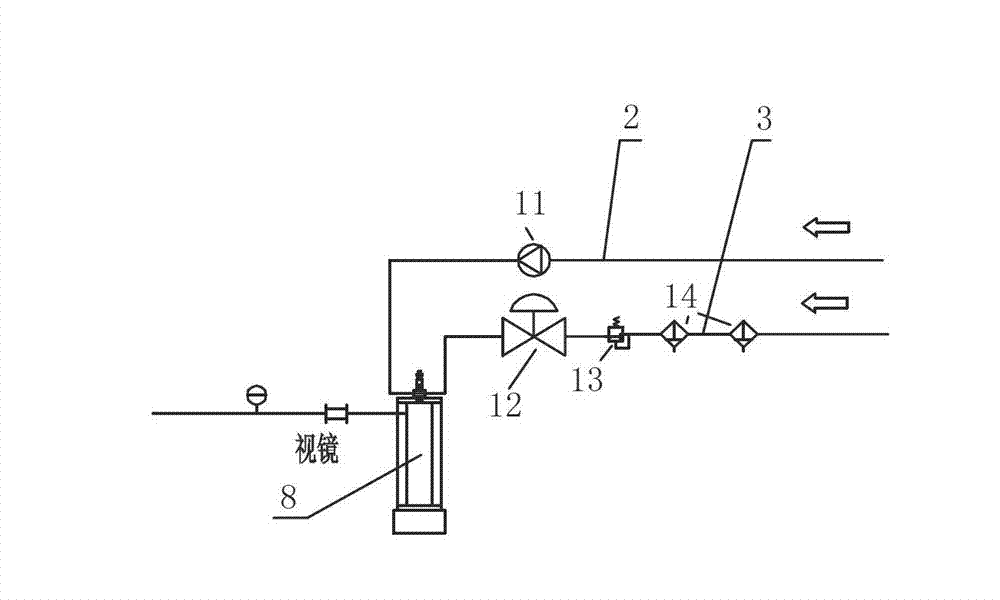

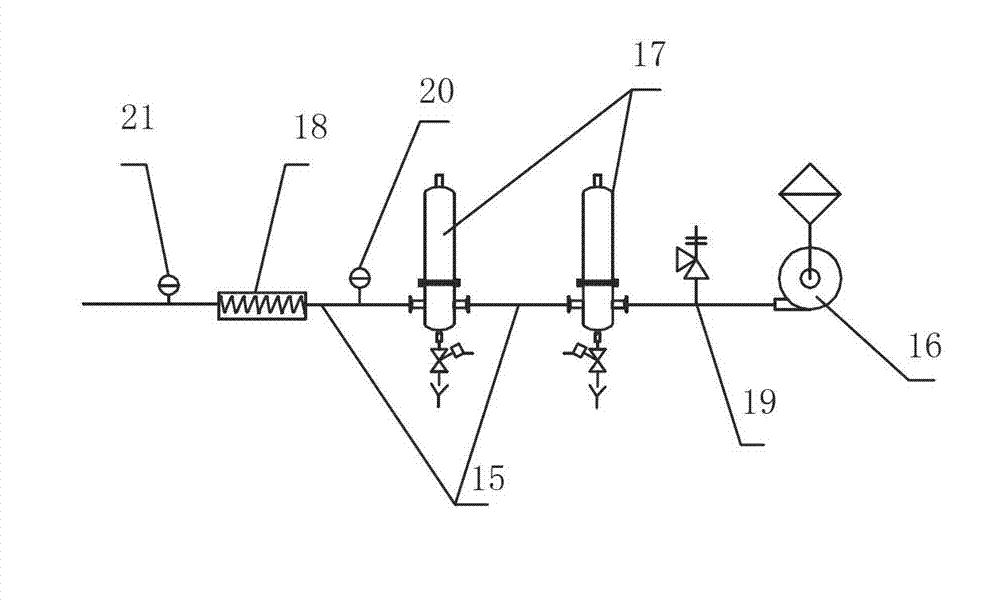

[0021] Refer to attached picture. The invention provides an air jet sterilization system, which uses sterile hot air to mix with an atomized sterilization medium, uses the high temperature of the sterile hot air to gasify the sterilization medium, and uses the gasified sterilization medium to sterilize the inner wall of the container , and use sterile hot air to mix with the vaporized sterilization medium, while strengthening the sterilization effect of the vaporized sterilization medium, it can speed up the processing speed of empty bottles.

[0022] The sterilization medium atomization unit uses high-pressure air to atomize the liquid sterilization medium while entering the gasification box through the atomization nozzle; the sterile hot air processing unit delivers the filtered and heated air from the outside to the gasification box. In the box, the temperature of the atomized sterilization medium is raised, and the sterilization medium is vaporized in the gasification box....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com