Method for manufacturing three-dimensional circuit

A manufacturing method and technology of three-dimensional circuits, applied in printed circuit manufacturing, circuits, printed circuits, etc., can solve problems such as insufficient circuit density, achieve good line size accuracy and conductor density, maintain stability, and have high material selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to further have a clear and detailed understanding and understanding of the structure, use and characteristics of the present invention, the preferred embodiments are now cited, and detailed descriptions are as follows in conjunction with the accompanying drawings:

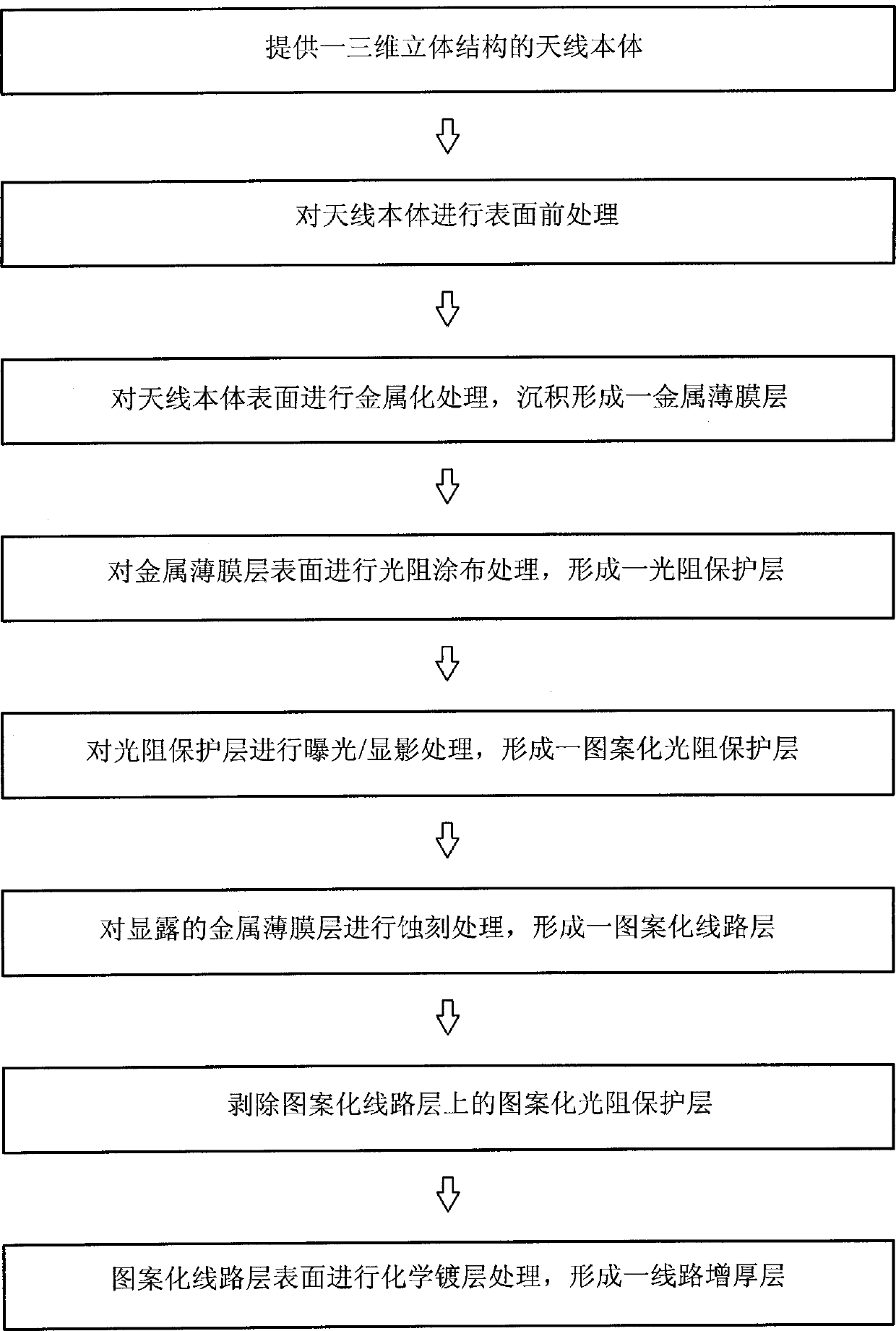

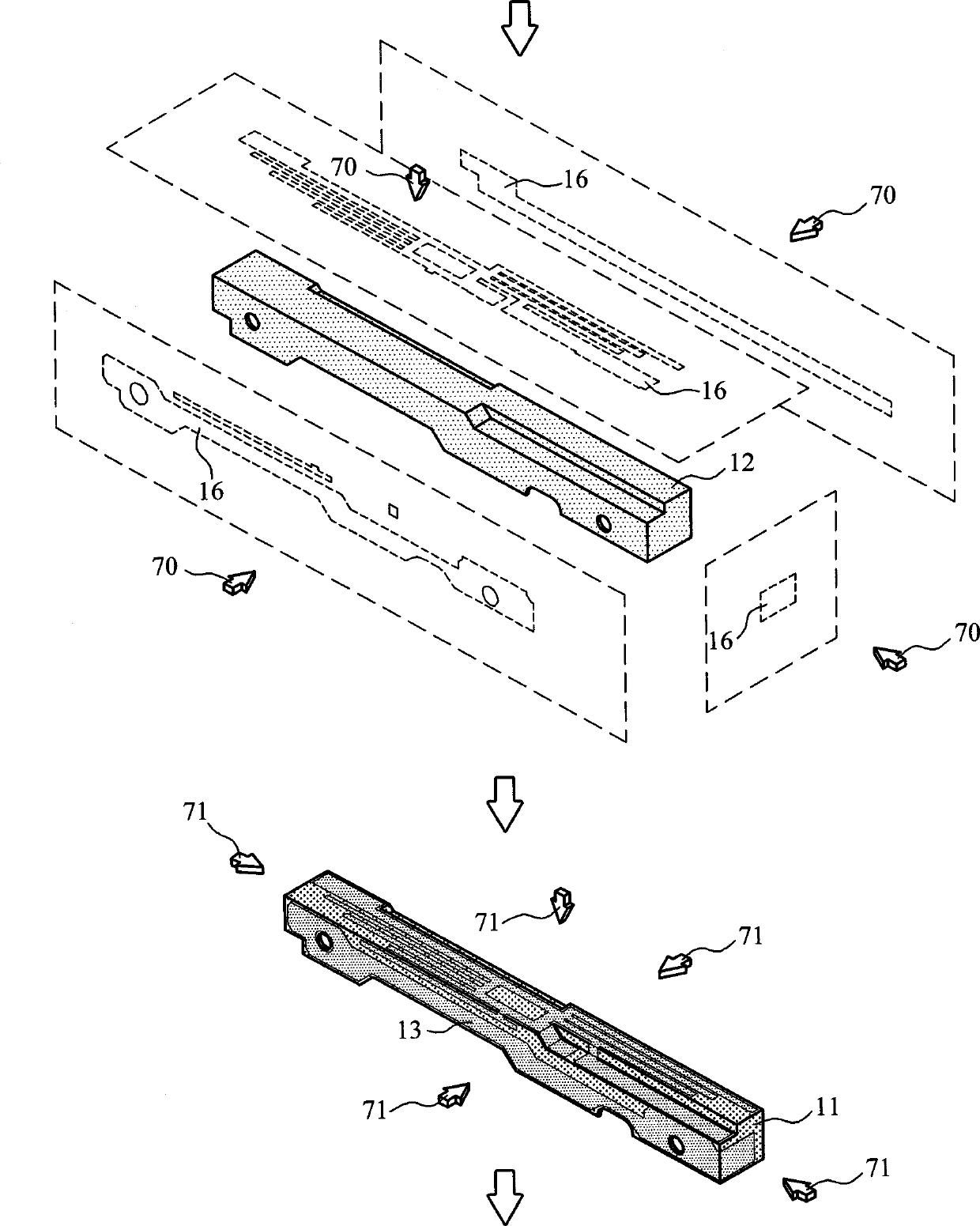

[0058] First, see figure 1 flow chart and Figure 2 to Figure 4 As shown in the structural diagram, in the first preferred embodiment, the manufacturing method of the three-dimensional antenna circuit of the present invention includes the following steps:

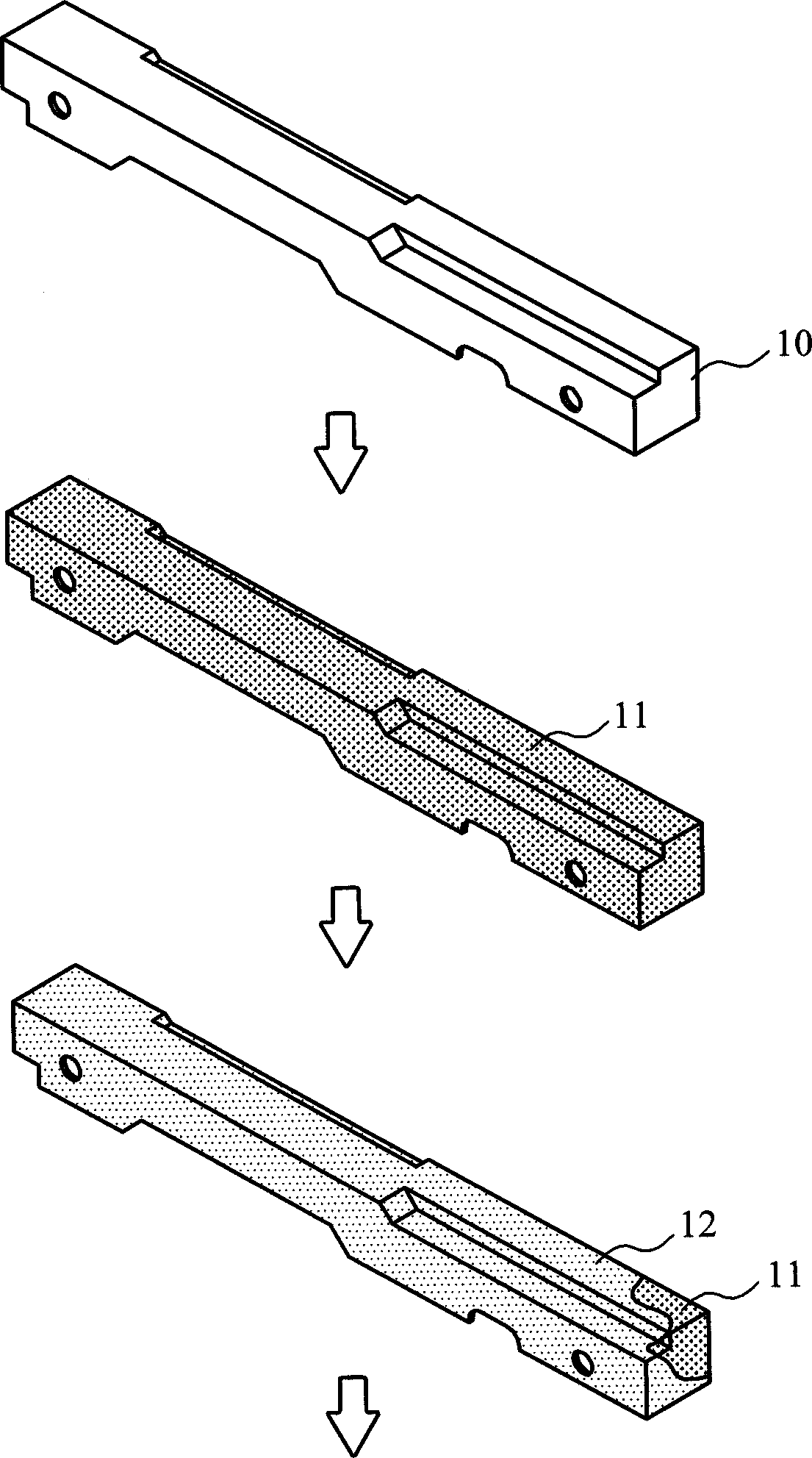

[0059] (1) An antenna body 10 with a three-dimensional structure is provided;

[0060] (2) carrying out surface pretreatment to antenna body 10;

[0061] (3) Carry out metallization treatment to the surface of the antenna body 10, deposit and form a metal thin film layer 11;

[0062] (4) Carry out photoresist coating treatment to the metal film layer 11 surface, form a photoresist protective layer 12;

[0063] (5) Exposing / developing 70 the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com