Gas-leading sealing structure of gas turbine

A sealing structure and gas turbine technology, which is applied in the direction of gas turbine devices, mechanical equipment, jet propulsion devices, etc., can solve the problems of complex assembly, cumbersome structure, and large amount of calculation, and achieve airflow loss reduction, simple structural design, and simple sealing structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

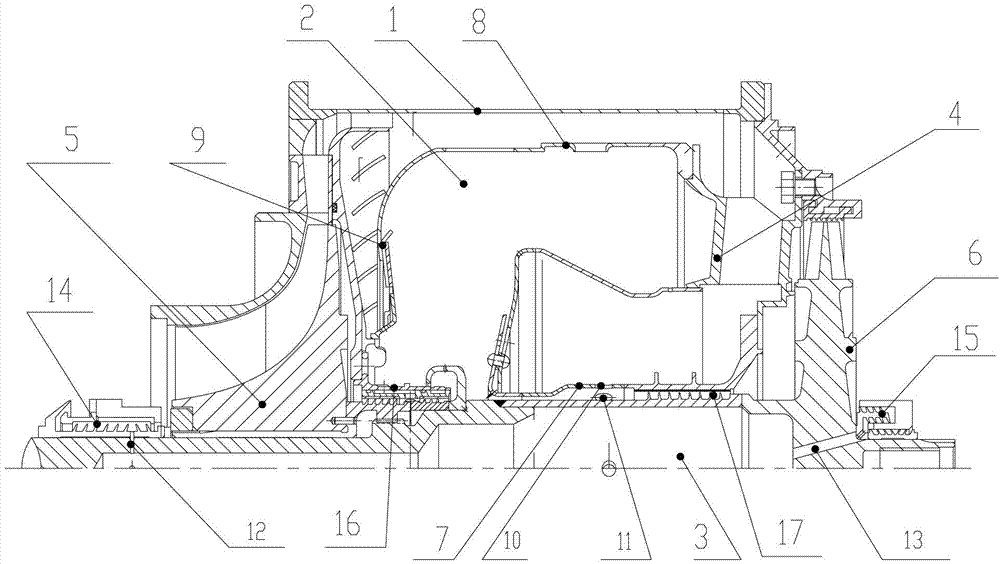

[0007] As shown in the figure, the gas turbine bleed air sealing structure includes a casing 1, a flame tube 2, a rotor 3 and a turbine guide hollow blade 4, and the rotor 3 is equipped with a compressor rotor 5 and a turbine rotor 6, and the flame The cylinder 2 includes an inner wall 7, an outer wall 8, and a front wall 9 and is equipped with a turbine guide hollow vane 4. A compressed air channel is provided between the casing 1, the outer wall 8, and the front wall 9. On the rotor 3 Grate tooth sealing structures 14, 15, 16, 17 are arranged at the front of the compressor rotor 5, behind the turbine rotor 6, the front wall 9 and the inner wall 7, and the inner wall 7 is provided with an air outlet hole 10, and the rotor 3 is located at the outlet The air hole 10 is provided with a tangential hole 11, a vent hole 12 is provided at the grate tooth sealing structure 14, and a vent hole 13 is provided at the grate tooth sealing structure 15, and both the vent hole 12 and the ven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com