System for feeding coal mine solid filling material

A technology for solid filling and coal mines, which is applied to fillings, mining equipment, safety devices, etc., can solve problems such as ground subsidence and danger, and achieve the effects of preventing blockage, alleviating the impact of falling, and reducing the degree of compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

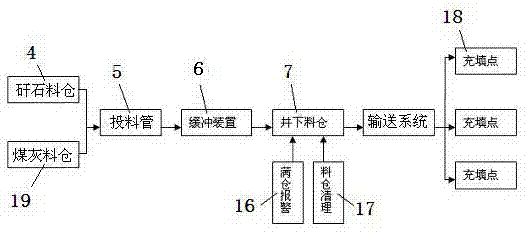

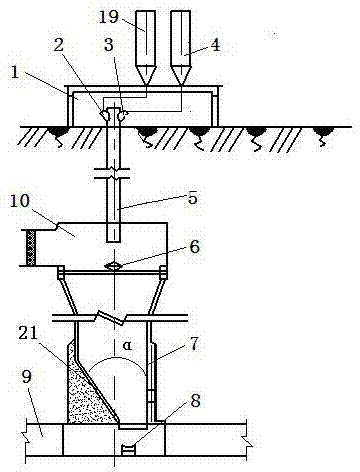

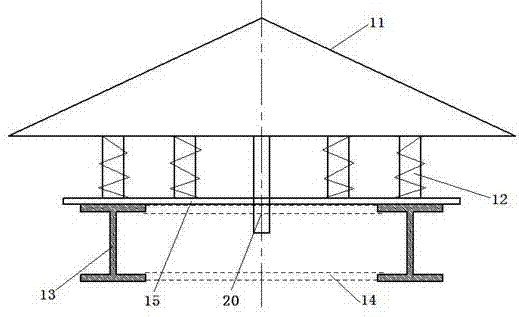

[0015] The coal mine solid filling material feeding system of the present invention is as figure 1 , figure 2 As shown, it includes a filling control room 1, a gangue silo 4, a coal ash silo 19, a feeding pipe 5, an underground airtight chamber 10, an anti-shock buffer device 6, an underground silo 7 and an underground conveying system. The feeding pipe is provided with gangue inlet 3 and fly ash inlet 2. The gangue silo is connected with the gangue inlet, and the coal ash silo is connected with the fly ash inlet. The anti-shock buffer device is located at the bottom of the downhole airtight chamber, and the feeding pipe 5 is connected with the downhole feed bin through the downhole airtight chamber 10, and the downhole feed bin is connected with the downhole conveying system. Anti-shock buffer device 6 is used to slow down the impact force of filling materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com