Stainless steel alloy for golf ball head

A golf head and stainless steel technology, which is applied in the field of stainless steel alloys, can solve problems such as easy wear of spherical grooves, easy deviation of angles, poor shock absorption performance, etc., and achieve the effect of not easy to wear, long contact time, and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A stainless steel alloy for a golf head of a preferred embodiment of the present invention comprises 1.89% manganese by weight, 1.12% silicon, 0.028% carbon, 6.54% nickel, 16.15% chromium, 2.75% copper, 0.21% nitrogen, the balance being iron.

[0018] The HRB value of the stainless steel alloy composed of the above elements is 74.5, and the material has good wear resistance. After solid solution and aging heat treatment, the tensile strength is 56.82 kgf / mm2, the yield strength is 34.00 kgf / mm2, the elongation is 24.00%, and the specific gravity is 7.81 g / mm2 cm3.

[0019]

Embodiment 2

[0021] A stainless steel alloy for a golf head of a preferred embodiment of the present invention comprises 1.67% manganese by weight, 1.34% silicon, 0.021% carbon, 7.25% nickel, 17.9% chromium, 3.1% copper, 0.31% nitrogen, the remaining proportion is iron.

[0022] The HRB value of the stainless steel alloy composed of the above elements is 74.8, and the material has good wear resistance. After solid solution and aging heat treatment, the tensile strength is 57.42 kgf / mm2, the yield strength is 33.9 kgf / mm2, the elongation is 27.32%, and the specific gravity is 7.80 g / mm2 cm3.

[0023]

Embodiment 3

[0025] A stainless steel alloy for a golf head according to a preferred embodiment of the present invention comprises 1.32% manganese by weight, 1.05% silicon, 0.03% carbon, 7.52% nickel, 17.12% chromium, 2.5% copper, 0.42% nitrogen, the remaining proportion is iron.

[0026] The HRB value of the stainless steel alloy composed of the above elements is 73.2, and the material has good wear resistance. After solid solution and aging heat treatment, the tensile strength is 61.68 kgf / mm2, the yield strength is 33.81kgf / mm2, the elongation is 35%, and the specific gravity is 7.85 g / mm2 cm3.

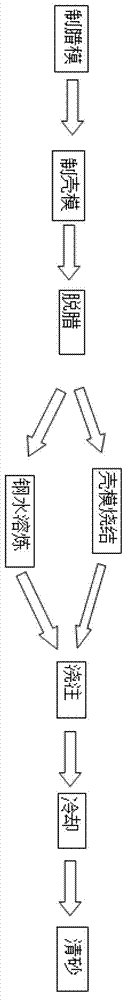

[0027] The manufacturing method of the stainless steel alloy used for the golf club head of the present invention generally includes the following steps: adding pure iron, ferrosilicon, ferromanganese, ferrochrome, carbon, copper and nickel into the high-temperature melting furnace as appropriate to form a molten alloy . By adding the above-mentioned raw materials to adjust the weight r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com