Liquid phenolic-type cyanate resin suitable for RTM (resin transfer molding) process

A technology of phenolic cyanate and phenolic resin, which is applied in the field of liquid cyanate resin and can solve problems such as short gel time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] After melting 1636g of phenol, put it in a three-neck glass flask equipped with a thermometer, reflux condenser and stirring device, raise the temperature to 70°C and add 87g of dilute sulfuric acid (10%). 652g of formaldehyde (37% aqueous solution) was added in batches, and the temperature was raised to 90°C for 6 hours. Neutralize to neutral with 10% sodium hydroxide solution. After cooling to room temperature, the crude product of phenolic resin was obtained. The crude product was vacuum rotary evaporated from room temperature to 150°C until no phenol vapor was present, then cooled to room temperature to obtain a brown yellow phenolic resin.

[0034] The obtained phenolic resin had an average molecular weight of 310 and a melting point of 60°C.

Embodiment 2

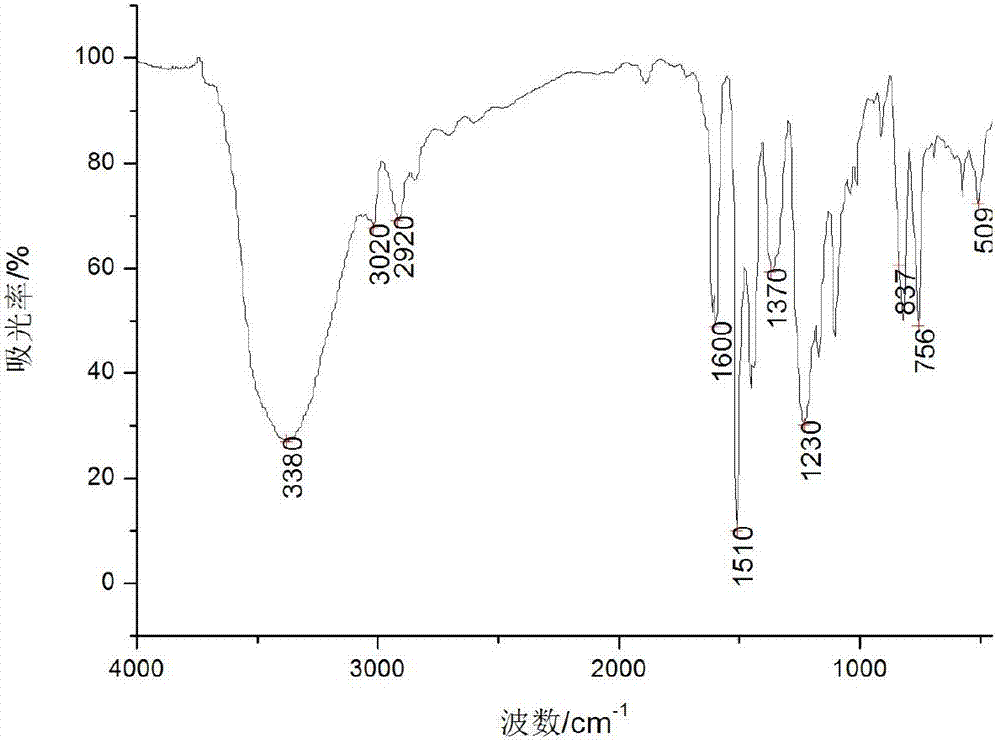

[0036] Get 200g acetone and add in the three-neck glass flask of thermometer, reflux condenser and stirring device, cool to-10 ℃, get 50g cyanogen bromide and phenolic resin in 20g example 1 and dissolve in acetone. 40 g of triethylamine was gradually added dropwise, and after the dropwise addition was completed, the temperature was raised to 5°C for 2 hours of reaction. After standing for 1 h, the salt was removed by filtration, and the crude product was obtained after distilling off acetone. Extract the crude product with dichloromethane, wash the extract with 5% hydrochloric acid, and separate the organic phase; wash three times with deionized water, then dry with magnesium sulfate; filter and distill off the solvent to obtain a liquid cyanate resin.

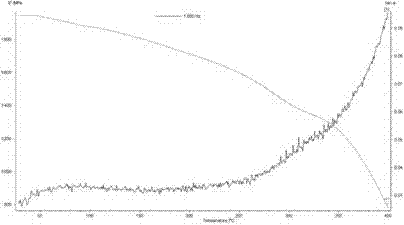

[0037] Phenolic cyanate resin has an average molecular weight of 390, a viscosity of 600cP at 20°C, and a thermal curing temperature of 200-300°C.

Embodiment 3

[0039] Get 200g of acetone and add in the three-neck glass flask of thermometer, reflux condenser and stirring device, cool to-10 ℃, get 50g of cyanogen bromide and 30g of phenolic resin in example 1 and dissolve in acetone. 40 g of triethylamine was gradually added dropwise, and after the dropwise addition was completed, the temperature was raised to 5°C for 2 hours of reaction. After standing for 1 h, the salt was removed by filtration, and the crude product was obtained after evaporating acetone. Extract the crude product with dichloromethane, wash the extract with 5% hydrochloric acid, and separate the organic phase; wash three times with deionized water, then dry with magnesium sulfate; filter and distill off the solvent to obtain a liquid cyanate resin.

[0040] Phenolic cyanate resin has an average molecular weight of 380, a viscosity of 580cP at 20°C, and a thermal curing temperature of 200-300°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com