Contact with function of controlling directional extension movement of vacuum arc

A motion function, vacuum arc technology, applied in the direction of contacts, circuits, electrical switches, etc., can solve the problems of reducing the mechanical strength of the contact system, the current-carrying density of the contacts, reducing the breaking current capacity of the switch, and increasing the production and processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

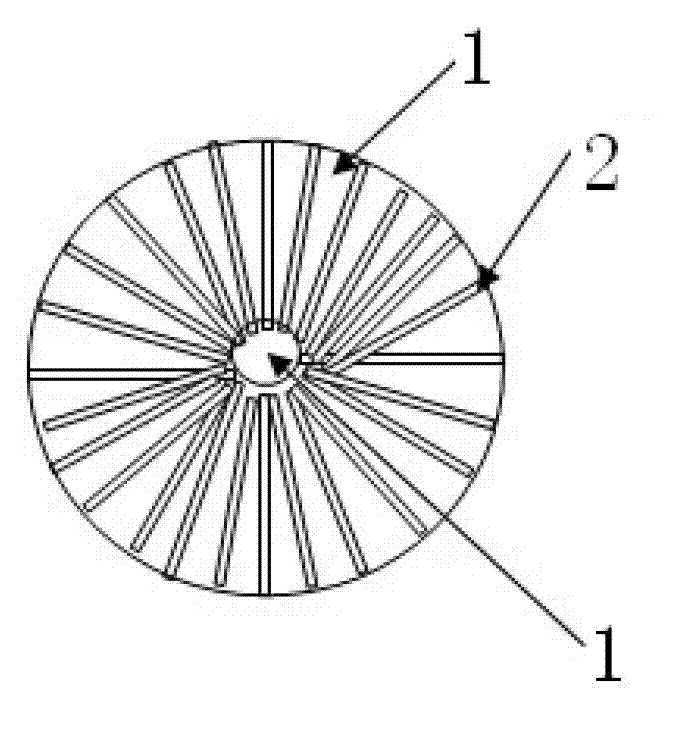

[0017] A contact with the function of controlling the directional expansion movement of the vacuum arc, the copper-based alloy material is a copper-chromium contact with a mass percentage of 47-52% chromium, and the second phase region contains 1-3% carbon, Carbon / CuCr contact area with 44-51% Cr, the second phase area is distributed radially from the center in the CuCr alloy matrix material, see figure 1 As shown, the number 1 indicates the contact material matrix, and the number 2 indicates the second phase region. The contact material matrix as a whole is fan-shaped, and the width of the nearly rectangular area of the second phase is 0.1-2 mm in cross section.

Embodiment 2

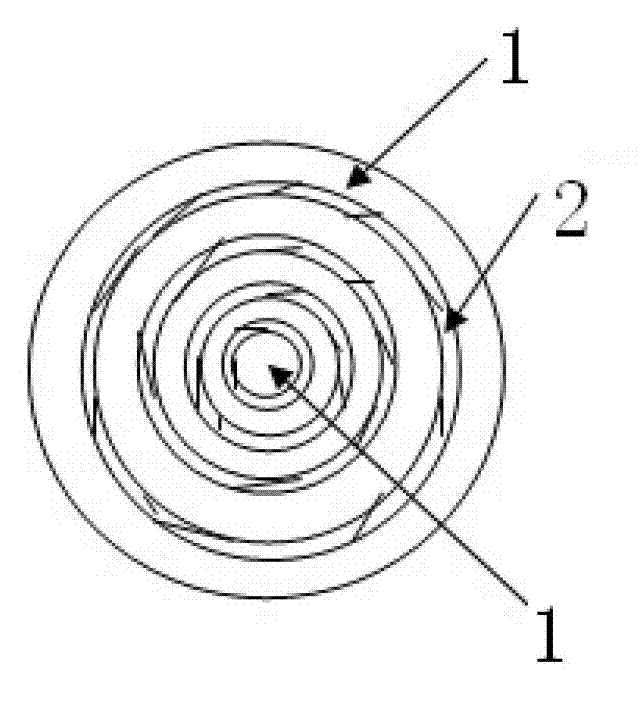

[0019] A contact with the function of controlling the directional expansion movement of the vacuum arc. The copper-based alloy material is a copper-chromium contact with a mass percentage of 22-28% chromium, and the second phase region is a carbon with a mass percentage of 1-3%. 19-27% chromium carbon / copper-chromium contact area, the second phase area is distributed in the copper-chromium alloy matrix material in a circular shape from the center, refer to figure 2 As shown, the number 1 indicates the contact material matrix, and the number 2 indicates the second phase region, and the width of the annular region of the second phase on the cross section is 0.1-2mm.

Embodiment 3

[0021] A contact with the function of controlling the directional expansion movement of the vacuum arc. The copper-based alloy material is a copper-chromium contact with a mass percentage of 22-28% chromium, and the second phase region is a carbon with a mass percentage of 1-3%. 19-27% chromium carbon / copper-chromium contact area, the second phase area is helical from the center, and the width of the second phase helix on the contact cross section is 0.1-2mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com