Method for performing coal mining and gangue cementation stripe filling simultaneously

A strip filling and cementing technology, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of inability to realize the synchronization of filling and working face, unfavorable high production and high efficiency of coal mines, time-consuming, and high capital costs, etc., to achieve reduction Ground site layout, fast and effective filling, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

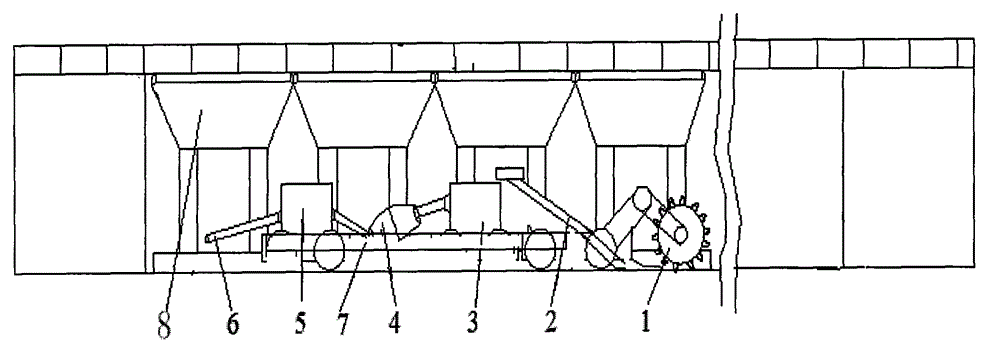

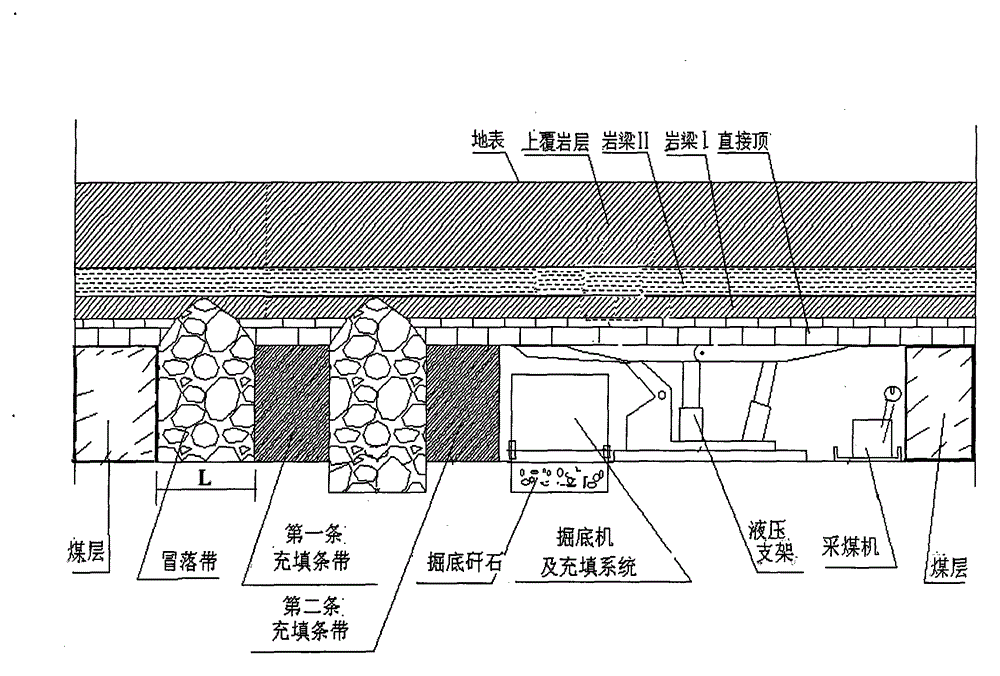

[0023] Referring to the accompanying drawings, the method of the embodiment of the present invention is further described.

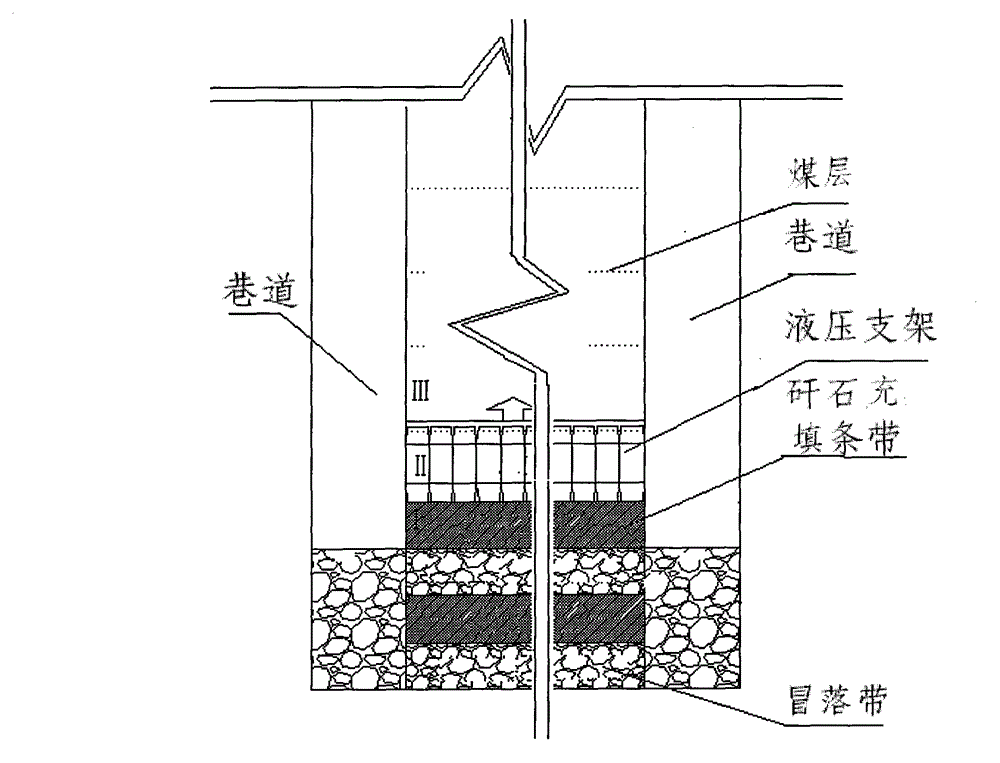

[0024] The arrangement of gangue cemented strips of the present invention is as follows: figure 1 , image 3 As shown, it is to arrange a gangue cemented strip at a certain distance in the goaf, and the specific construction steps are as follows:

[0025] The first step, first of all, the shearer is advanced by the cutting hole according to the conventional method. When the goaf after the coal mining face advances is the width of the designed caving zone, it is the position of the filling strip at this time. Move the filling bracket to the filling position, and place the filling bag manually under the protection of the filling bracket; at the same time, the working face continues to advance;

[0026] Among them, the width L of the caving zone is: the width L=20m of the hard roof caving zone with a compressive strength exceeding 60MPa; the width L=10m o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com