Sliding support hinge with five-connecting-rod structure

A sliding stay hinge and five-link technology, applied in the field of sliding stay hinges for safety casement windows, can solve problems such as increased wind force and moment, deformation of sliders, glass damage and falling off, etc., to increase friction and resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

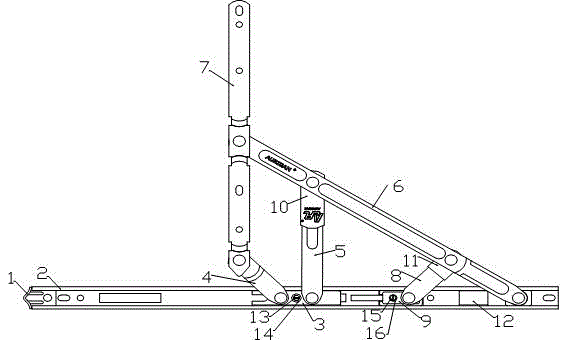

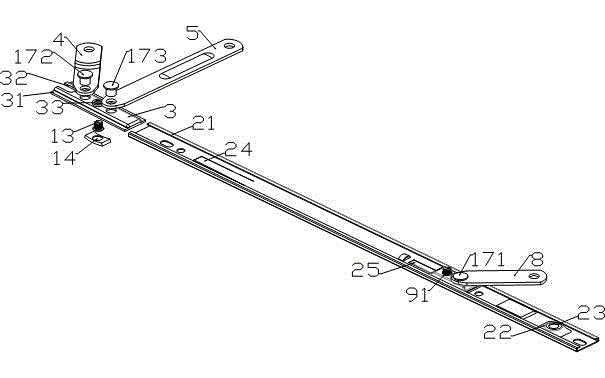

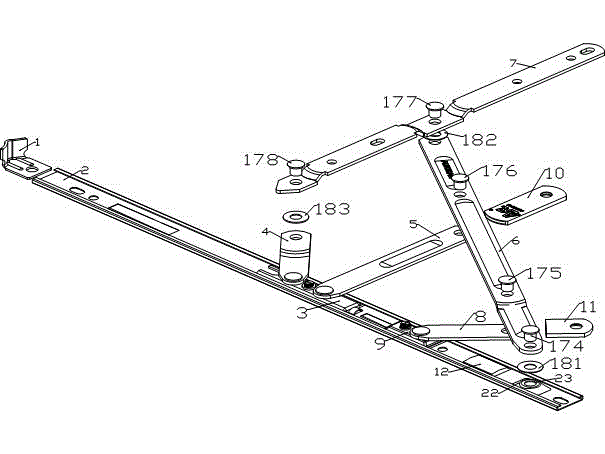

[0024] Refer to 1, figure 2 , image 3 As shown, a sliding stay hinge with a five-link structure of the present invention includes a guide top angle 1, a slide rail 2, a first slider 3, a first support arm 4, a second support arm 5, a third support arm 6, a top Support cantilever 7, the fourth support cantilever 8, the second slide block 9, adjusting screws 13,15, friction pads 14,16, nylon pads, nylon sleeve pads 10,11, supporting pads 12 and other accessories. The slide rail 2 has an edge 21 folded inward, and near one end there is a flange 22 (formed by stamping process) higher than the edge 21 of the slide rail, and the flange 22 has a rivet hole 23 .

[0025] The sliding stay hinge is assembled as follows: the slider 9 is hinged with the fourth support arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com