Method for separating glucose and allulose from high fructose corn syrup

A technology of allulose and fructose syrup, which is applied in the production of glucose, sugar production, sugar production, etc., can solve the problems of complicated purification steps, and achieve the effects of high purity, reduced pipeline reduction, and simplified system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

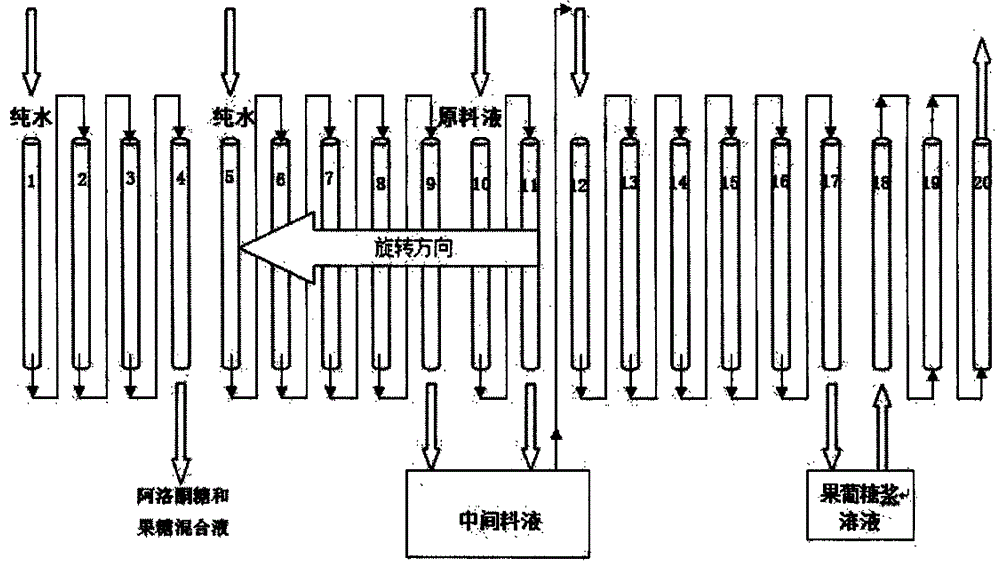

[0027] Such as figure 1 As shown, the continuous chromatographic separation system adopted in this embodiment has 20 built-in separation units, and calcium ion chelating resin is filled in each separation unit; the continuous chromatographic separation system is divided into five regions, and each region is composed as follows:

[0028] Adsorption zone (10#-11# separation unit): Contains 2 separation units, adopts the forward series feeding method, the raw material liquid passes through the 11# separation unit after the two separation units in turn, and the intermediate feed liquid from the 11# separation unit enters the intermediate material tank;

[0029] Washing area (5#-9# separation unit): Contains 5 separation units. The separation unit adsorbed by the adsorption area is washed in a forward series with pure water, and the washing liquid f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com