Method for manufacturing nano pipes

A technology of nanotubes and nanomaterials, which is applied in the field of preparation of nanotubes, can solve the problems of complicated steps and inability to assemble multiple nanomaterials, and achieves the effect of simple preparation method and low requirements for preparation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The embodiment of the present invention discloses a method for preparing nanotubes, comprising the following steps:

[0031] (A) Dropping nanomaterials or nanomaterial assemblies onto a support covered with a carbon film to obtain a composite carbon film;

[0032] (B) making the composite carbon film described in step (A) form cracks to obtain a composite carbon film with cracks;

[0033] (C) The composite carbon film with cracks described in step (B) is irradiated with electron beams to curl to obtain nanotubes.

[0034] According to the present invention, firstly, the nanomaterial or the nanomaterial assembly is dropped onto the support covered with the carbon film to obtain the composite carbon film. In order to facilitate the formation of the composite carbon film, the assembly of rice materials or nanomaterials is first dispersed in a solvent to obtain a mother liquor; then the mother liquor is added dropwise on a support covered with a carbon film to obtain a com...

Embodiment 1

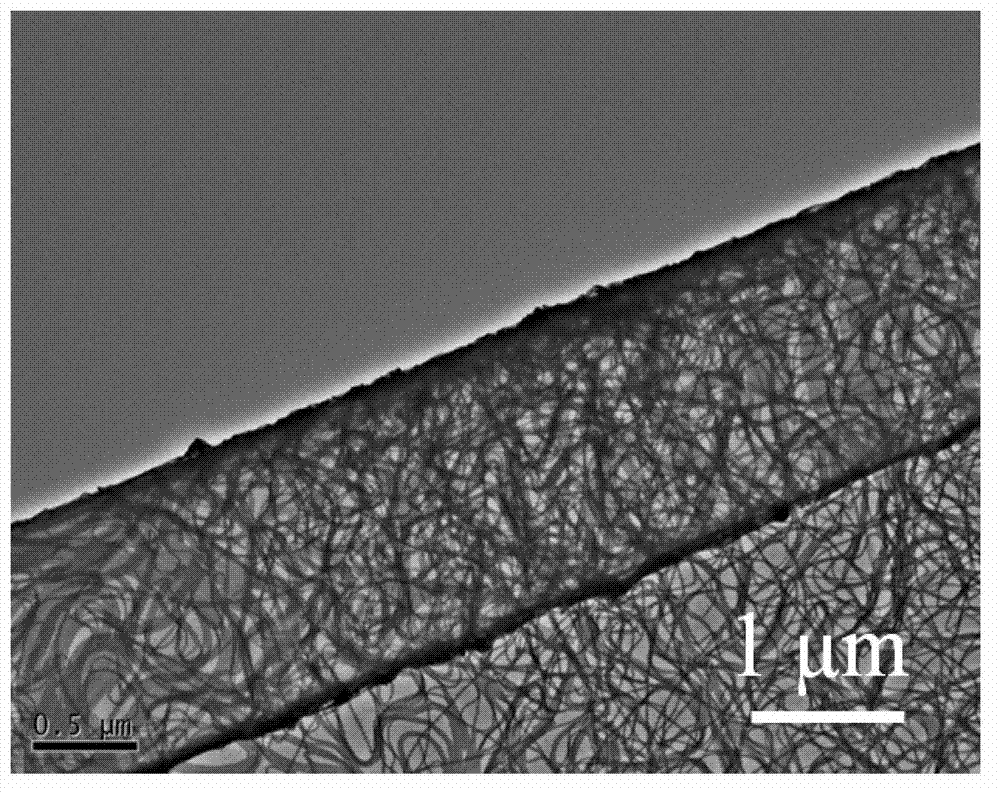

[0046] Add 1.000 grams of polyvinylpyrrolidone (PVP) with a molecular weight of 40,000, 0.0922 grams of sodium tellurite (Na 2 TeO 3 ), 33 milliliters of water, 1.67 milliliters of hydrazine hydrate with a mass percentage of 85% and 3.33 milliliters of ammonia water with a mass percentage of 25 to 28%; use magnetic stirring for 10 minutes to make it reach a homogeneous solution; put the polytetrafluoroethylene reactor into The steel sleeve was reacted at 180°C for 3 hours, and after natural cooling, a mixed solution containing tellurium nanowires with a diameter of 7 nanometers and a length of hundreds of microns was obtained.

[0047] Take 5 ml of the above-mentioned mixed solution of tellurium nanowires, add 12 ml of acetone, perform centrifugation at 5000 rpm for 5 minutes, and remove the supernatant. Add 12 ml of water, disperse evenly, perform centrifugation at 5000 rpm for 5 minutes, and remove the supernatant. Add 12 ml of ethanol, disperse evenly, perform centrifugat...

Embodiment 2

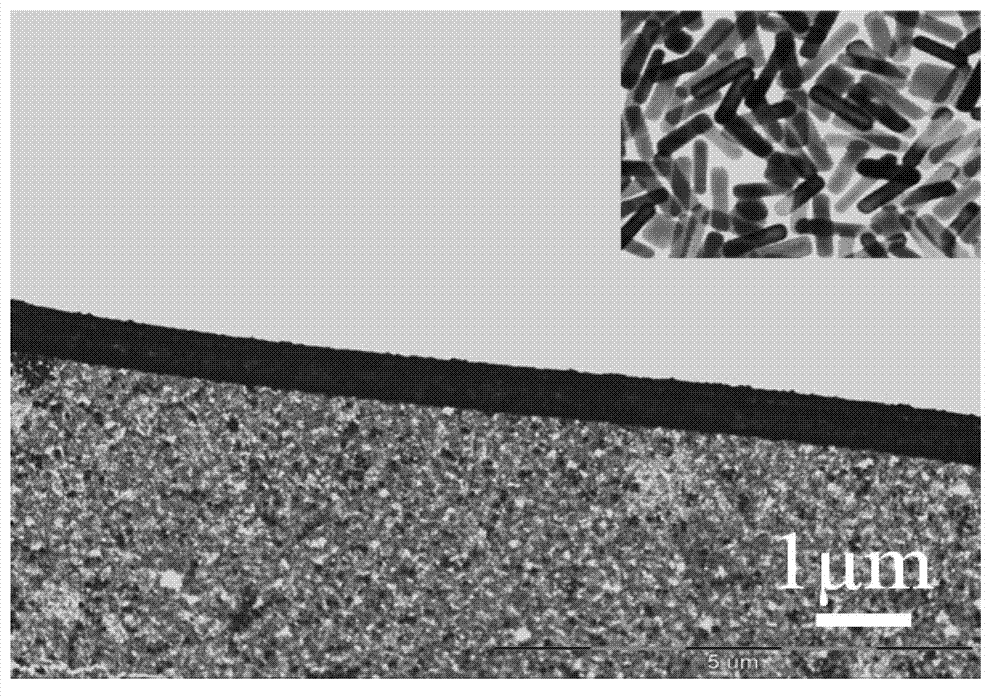

[0050] Take 0.130 g of copper acetylacetonate, 0.073 g of zinc acetate, 0.045 g of tin chloride and 0.033 g of sulfur and add them to 10 ml of oleylamine, stir evenly, then add them to a 25 ml three-necked flask; then heat to 110°C under nitrogen atmosphere , heated at 110°C for 30 minutes, the solution turned brown. Then heated to 280° C., and heated at 280° C. for 1 hour to obtain a mixed solution containing copper, zinc, tin and sulfur nanoparticles.

[0051] Take 5 ml of the above-mentioned mixed solution containing copper-zinc-tin-sulfur nanoparticles, add 12 ml of n-hexane, centrifuge at 5000 rpm for 5 minutes, and remove the supernatant. Add 12 ml of n-hexane, disperse evenly, perform centrifugation at 5000 rpm for 5 minutes, and remove the supernatant. Add 12 ml of ethanol, disperse evenly, perform centrifugation at 5000 rpm for 5 minutes, and remove the supernatant. Add 1 milliliter of ethanol and disperse evenly to form a mother liquor, then drop the mother liquor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com