Technique of monitoring abrasion of brake linings by optical fiber sensing

A technology of brake pads and sensor monitoring, which is applied in the field of monitoring the wear status of brake pads, can solve problems such as failure to ensure driving safety, failure of the braking system, and wear of brake pads, so as to save time and money, avoid safety accidents, and be easy to implement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

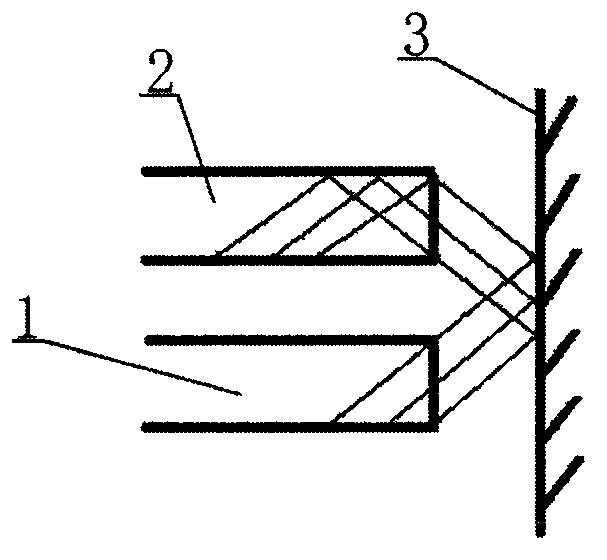

[0017] See attached figure 1 As shown, the optical fiber displacement sensor is a component that accurately measures displacement. It has the characteristics of low cost and high temperature resistance. The existing mature application technology is suitable for application in the environment of the braking system environment. Its working principle is that the light beam is projected onto the reflective surface 3 at a certain angle through the output port 2, and the relationship between the reflective surface 3 and the output port 2 or the receiving light can be calculated according to the parameters such as the area, intensity, and incident angle of the light received by the receiving port 1. The relative position of port 1 is used as a reference to calculate the relative displacement of the object.

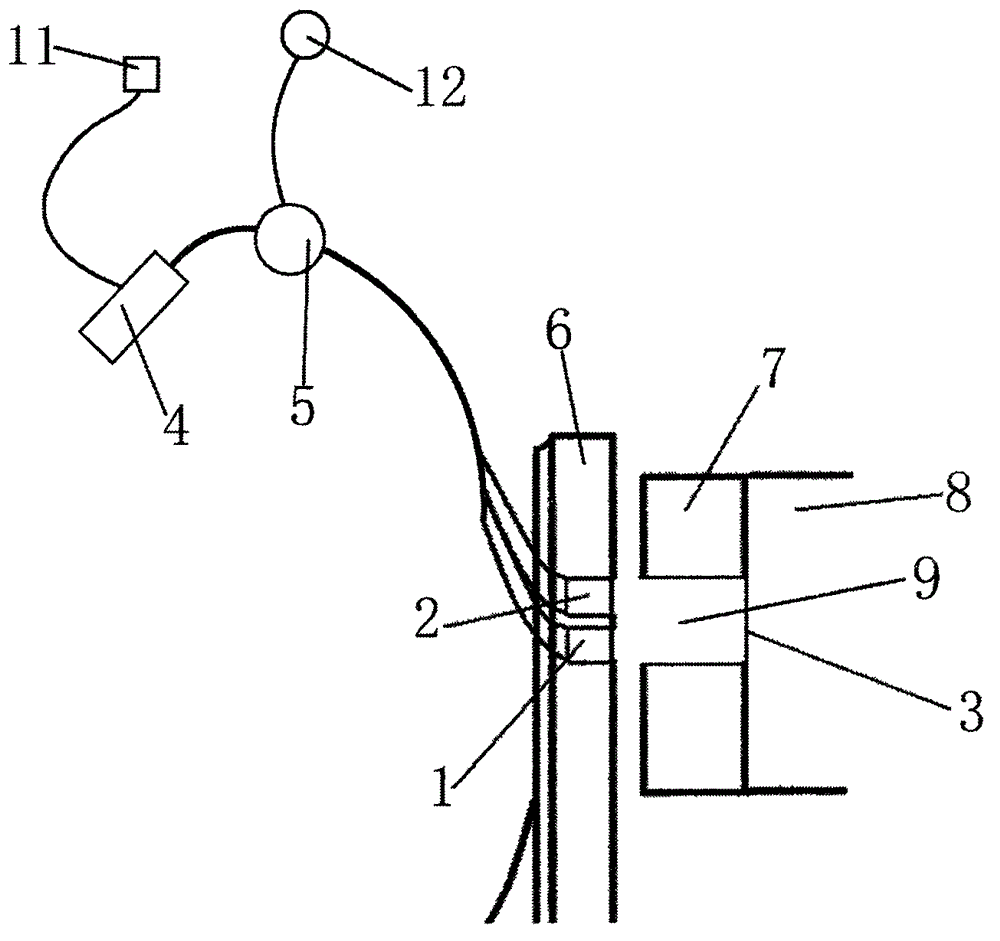

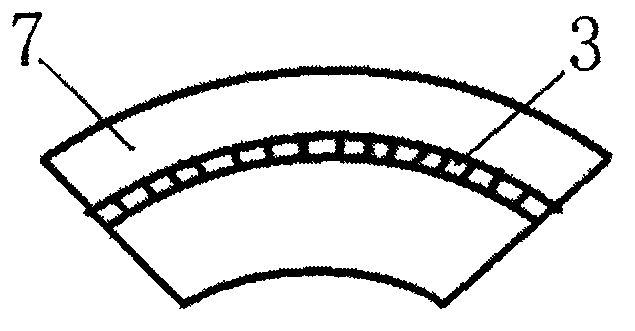

[0018] See attached figure 2 , 3 As shown, the current disc brake includes a brake disc 6 and a brake pad, and the brake pad includes a steel plate 8 and a friction block 7 fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com