Gas bulging forming method of large-sized thin-walled aluminum alloy ball-segment skin

A large-scale, aluminum alloy technology, applied in the field of precision sheet metal processing, can solve the problems of poor integrity of parts, high cost, difficult control of shape accuracy, etc., achieve high dimensional accuracy and surface quality of parts, eliminate residual stress, and mold manufacturing accuracy. Easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

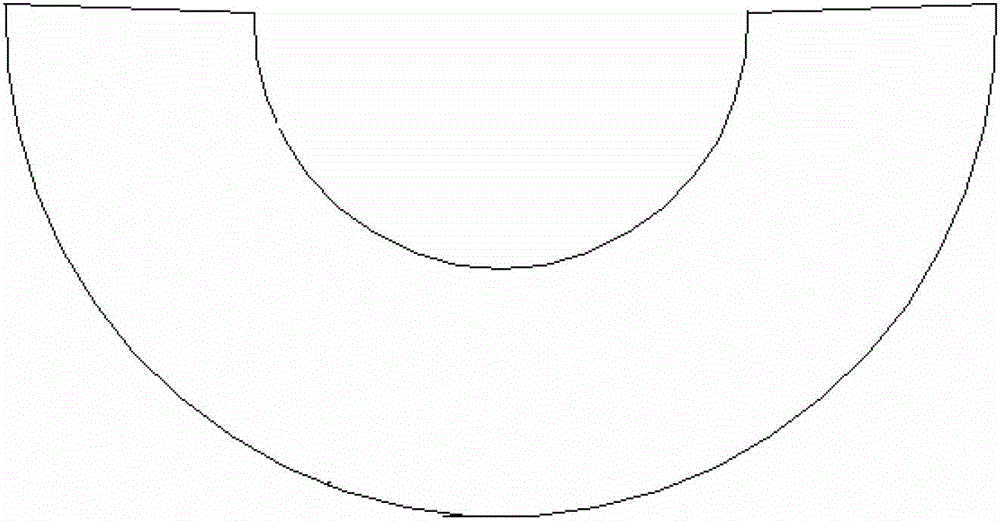

[0033] The specific implementation method is carried out according to the following process steps: the first step is to increase the process allowance: determine the process allowance, the size of the process blocking plate and the process flange according to the size of the ball segment skin, and determine the welding position. The second step of blanking: prepare the fan-shaped plate of the spherical segment skin. The process allowance of the large end is to increase 20mm in the height direction, and the process allowance of the small end is to increase 25mm in the height direction. Calculate the fan-shaped plate after increasing the process allowance. Unfolded length, see figure 2 , Use laser cutting or CNC punching method to place a single blank; similarly, place a single blank for the process blocking plate and process flange; remove the slag and deburr the blank. The third step is pre-forming: use a general-purpose circular machine to circle the fan-shaped sheet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com