Kitchen garbage disposal method

A kitchen waste and treatment method technology, applied in the field of environmental protection, can solve problems such as secondary pollution, easy pollution, complex components, etc., and achieve the effect of strong processing capacity and high degree of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

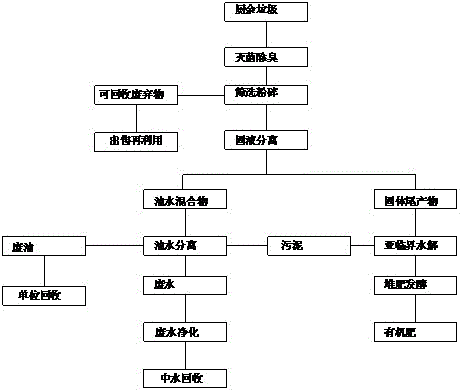

[0023] Such as figure 1 As shown, the kitchen waste is firstly deodorized and disinfected, that is, the kitchen waste is sprayed with hydrolytic protease; then the fully automatic sorting is carried out to screen the recyclable waste, which is classified and sold for reuse, and the rest of the organic waste is crushed. After crushing, it enters the solid-liquid separation system through the automatic feeding system for treatment; the solid-liquid separator separates the suspended solids and solids above 2mm, and squeezes and dehydrates them to form tail products. The oil and water are discharged into the oil-water separator for oil-water separation. The solid tail product is subjected to subcritical hydrolysis treatment, and the tail product after subcritical hydrolysis treatment is subjected to dynamic fermentation. After 2-3 days of dynamic fermentation, it becomes an organic matter improver for the soil. It can also be made according to different purposes. Compound special...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com