Textile machine vision detection method and system

A visual inspection and textile machine technology, applied in the direction of measuring devices, optical testing of flaws/defects, and material analysis through optical means, can solve the problems of low automation of the inspection process, low intelligence of algorithms, and high cost of visual inspection. It achieves the effect of facilitating transmission, good image quality and low labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A textile machine visual inspection method, the method includes,

[0047] Step 1, image acquisition, through the sliding of the industrial camera on the sliding table structure, image acquisition is performed on the cloth surface of the textile machine during the weaving process;

[0048] Step 2, image analysis and processing, intelligent analysis and processing of image layering, image magnification, image deshaking, image anti-reflection, image halo removal and image dust removal are performed on the collected cloth image through the embedded host computer, and the cloth is judged Whether the surface image is flawed, when the cloth image is flawed, then perform step 3, otherwise repeat step 2 to analyze and process the cloth image collected in the next frame;

[0049]Step 3, the analyzed cloth image is alarmed and displayed through the human-computer interaction module, and controlled through the control module. Since the industrial camera collects the cloth image of...

Embodiment 2

[0060] On the basis of Embodiment 1, the image enlargement process includes, when there is a defect in the cloth image, sending a control command to the control module through the human-computer interaction module;

[0061] The control module automatically adjusts the zoom distance of the industrial camera lens according to the received control command, and enlarges the cloth image with defects; and analyzes the image details of the enlarged cloth image. The analysis of the image details mainly includes the analysis of the broken warp and weft of the cloth surface. The specific image is based on the attached Figure 6 And attached Figure 7 .

[0062] The image is analyzed by adjusting the lens zoom distance of the industrial camera through the control module, which has a high degree of automation and is easy to operate.

Embodiment 3

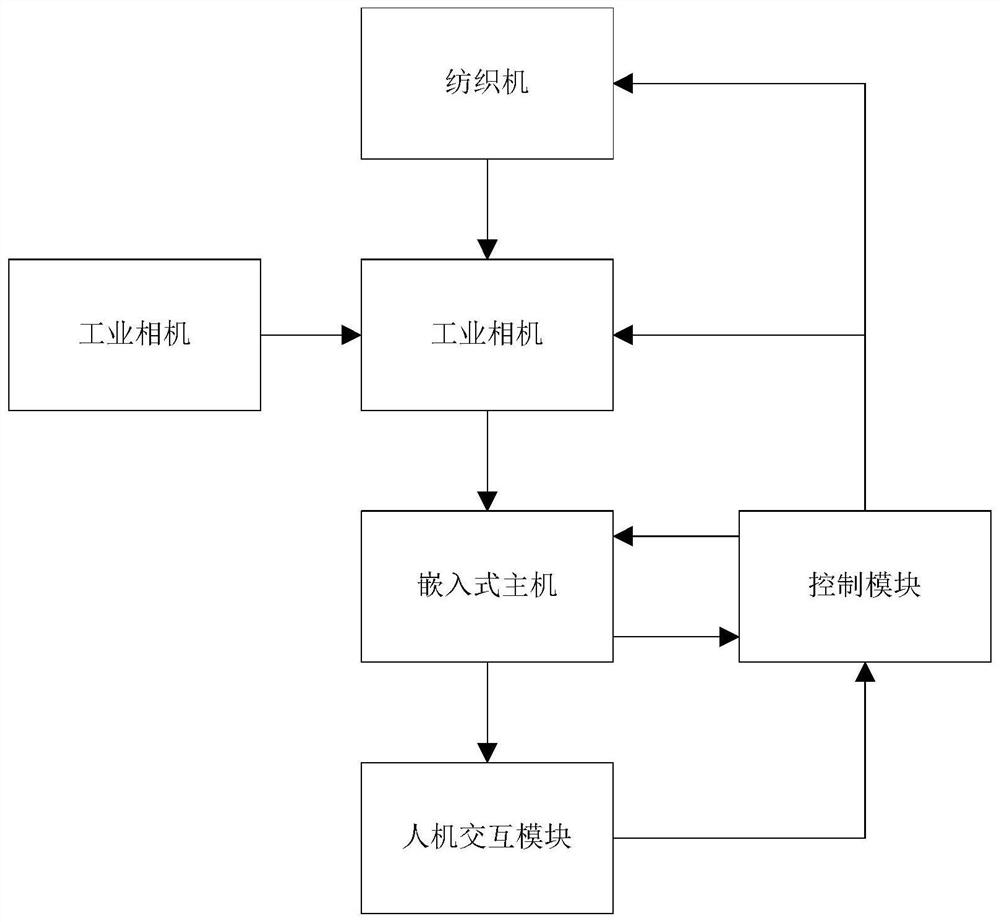

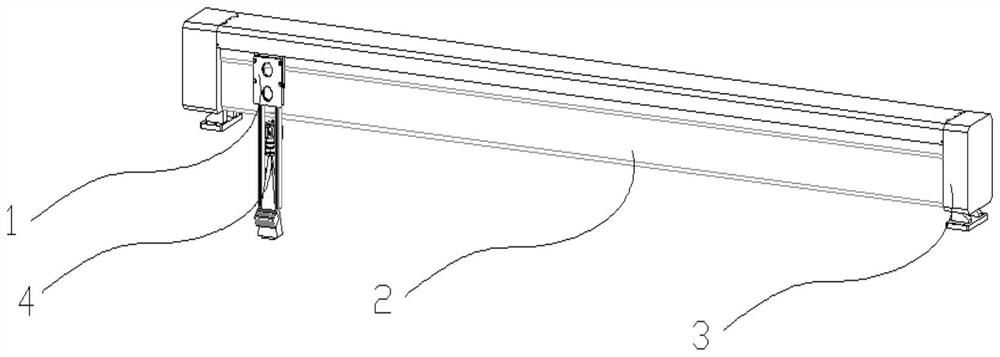

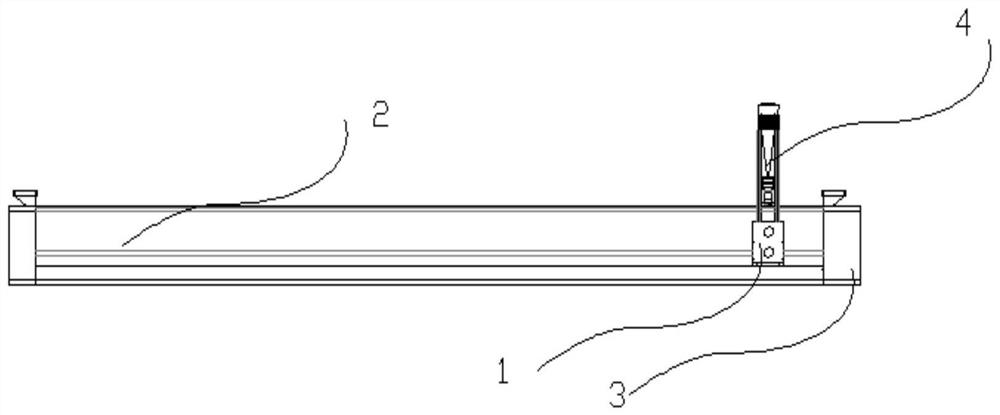

[0064] On the basis of the above-mentioned embodiments, the textile machine visual inspection system realized by the textile machine visual inspection method includes a slide mechanism, an industrial camera, an embedded host, a human-computer interaction module and a control module,

[0065] The industrial camera is installed on the sliding table mechanism, and the industrial camera moves with the movement of the sliding table mechanism;

[0066] The industrial camera is connected to the embedded host, and the image is transmitted to the embedded host through the TCP / IP network protocol; the embedded host performs image layering, image enlargement, image deshaking, image dereflection, and image Intelligent analysis and processing of halo removal and image dust removal, and send the intelligently analyzed and processed images to the human-computer interaction module;

[0067] The human-computer interaction module is connected with the control module, and transmits the received ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com