Molecular sieve aggregate and its preparation method

A molecular sieve and molecular technology, applied in the field of molecular sieve aggregates and their preparation, can solve problems such as difficult separation, and achieve the effects of increasing specific surface area, simple synthesis process, and reducing manpower and financial resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

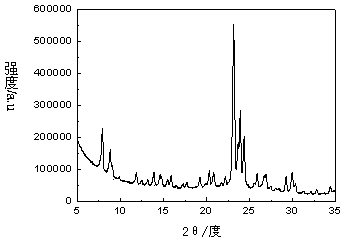

Image

Examples

preparation example Construction

[0029] The preparation method of the molecular sieve aggregate of the present invention enables the molecular sieve to be easily separated and filtered, constructs multi-stage channels, and maintains the catalytic activity of the molecular sieve. The preparation steps are as follows:

[0030] (1) Synthesizing molecular sieves with crystal grains smaller than 300 nm according to a known method, and using the resulting synthetic slurry in step (3);

[0031] (2) Synthesize mesoporous silica sol according to a known method;

[0032] (3) Add the mesoporous silica sol in step (2) directly into the synthetic slurry obtained in step (1), stir for 0.5-5 hours and then filter directly or continue heating at 50-195 °C before filtering, washing and drying Finally, molecular sieve aggregates are obtained.

[0033] Molecular sieves in step (1) can include Silicalite-1, Silicalite-2, ZSM-5, ZSM-11, TS-1, TS-2, Beta, Y-type molecular sieves, etc., more preferably TS-1, ZSM-5 and Beta Molecul...

Embodiment 1

[0034] Example 1 Preparation of mesoporous silica sol

[0035] Method 1: Refer to the synthesis method in the literature Kazuyuki Kuroda, Chem. Commun., 2009, 5094–5096 to synthesize mesoporous silica sol. Tetramethyl orthosilicate (TMOS) was used as the silicon source, and triethanolamine (TEAH 3 ) as the alkali source, and cetyltrimethylammonium bromide (CTAB) as the mesoporous directing agent. Dissolve CTAB in TEAH 3 In the aqueous solution, stir at 80 ℃ for 30 minutes to completely dissolve CTAB, add TMOS to the supernatant, and the ratio of the amount of substances in the final system is TMOS : TEA : CTAB : H 2 O = 1 : 0.25 : 0.5 : 1200, and continued stirring at 80°C for 2 hours to obtain a mesoporous silica sol.

[0036] Method 2: See the synthesis method in the literature Kun Zhang, Microporous and Mesoporous Materials, submitted, doi:10.1016 / j.micromeso: use tetramethylorthosilicate (TMOS) or tetraethylorthosilicate (TEOS) as the silicon source , with triethanolam...

Embodiment 2

[0038] Example 2 Preparation of TS-1 molecular sieve nanoparticles

[0039] Tetraethyl orthosilicate (TEOS) was used as the silicon source, tetrapropylammonium hydroxide (TPAOH) was used as the template, tetrabutyl titanate (TBOT) was used as the titanium source, and an appropriate amount of water and isopropanol was used as the Solvent; material molar ratio TPAOH: TEOS is 0.18, 0.27, 0.35; water: silicon source is 18, 30, 50; titanium source: silicon source is 0.025, 0.02; isopropanol: titanium source mass ratio is 10. First, dissolve TEOS in TPAOH. After TEOS is hydrolyzed, add TBOT dissolved in isopropanol in an ice-water bath, stir at room temperature for 30 minutes, and then distill alcohol in hot water at 70°C. Add an appropriate amount of water, continue to stir at room temperature for 30 minutes, and put it into a stainless steel self-generating pressure reactor with a polytetrafluoroethylene liner for crystallization. The crystallization temperature is 160-180 ℃, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com