Flue fire extinguishing purifier for roasting furnace

A technology for roasting furnaces and purifiers, applied in furnaces, furnace components, fire rescue, etc., can solve problems such as inability to accurately set cleaning time, heavy workload, and lack of timely fire extinguishing means, and achieve simple structure, low cost, and satisfactory The effect of the demand on the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

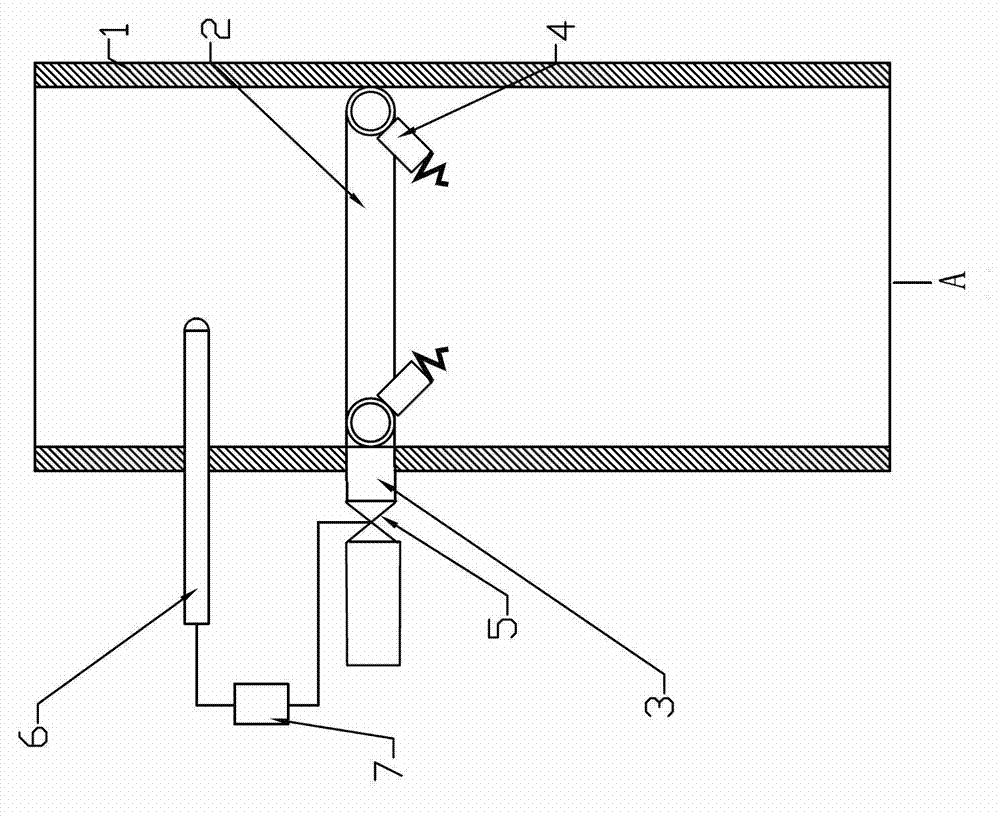

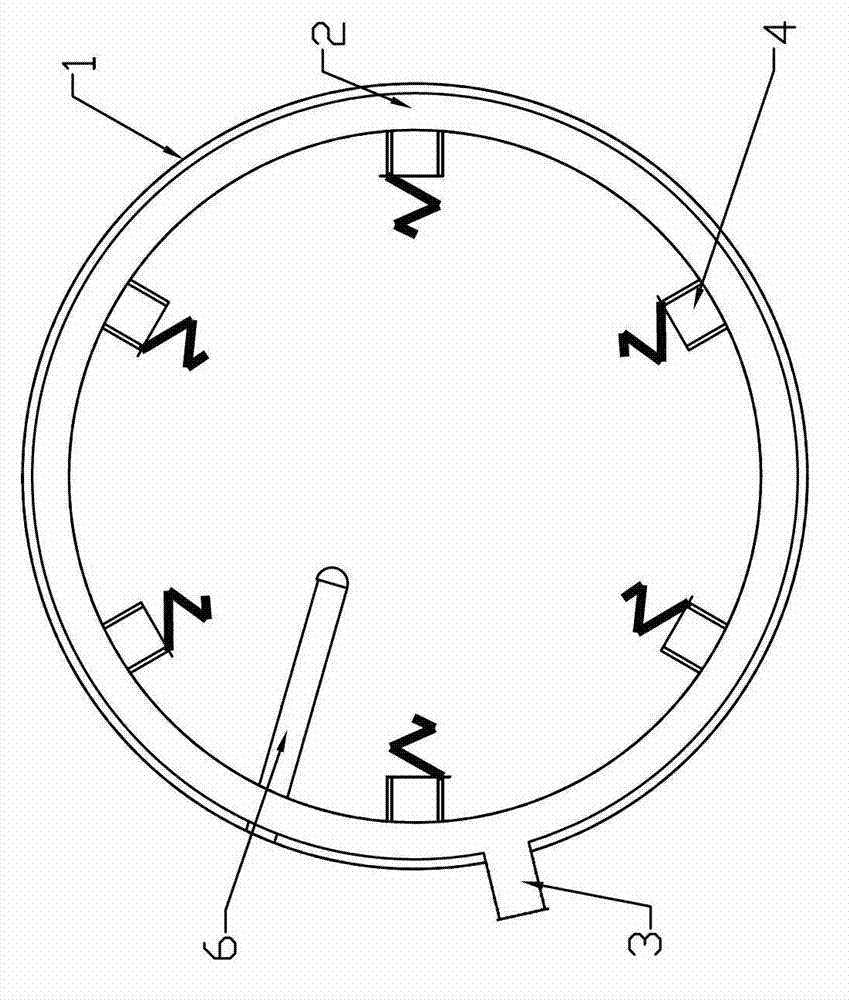

[0018] Such as figure 1 Shown, a kind of roasting furnace flue fire extinguishing purifier of this invention is characterized in that, comprises outer pipe 1, coil pipe 2, water inlet pipe 3, nozzle 4, electromagnetic valve 5, thermocouple 6 and control instrument 7, described The outer pipe 1 is a pipe with openings at both ends. The coiled pipe 2 is welded on the inner wall of the outer pipe 1 and communicated with the water inlet pipe 3. The coiled pipe 2 is provided with several nozzles 4; the water inlet pipe 3 passes through the outer pipe The electromagnetic valve 5 is connected to the water pipe, the thermocouple 6 is fixed in the outer pipe and connected to the control instrument 7, and the control instrument 7 is connected to the electromagnetic valve 5; the coil 2, the water inlet pipe 3 and the nozzle 4 are all made of stainless steel material.

[0019] Preferably, the nozzle 4 is composed of a nozzle base and a nozzle, the nozzle base is welded on the coil, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com