Tea sugar and method for preparing same

A technology of tea sugar and tea powder, which is applied in confectionary, confectionery industry, food science, etc., to achieve the effect of avoiding the reduction of efficacy, wide range of teas, and various types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

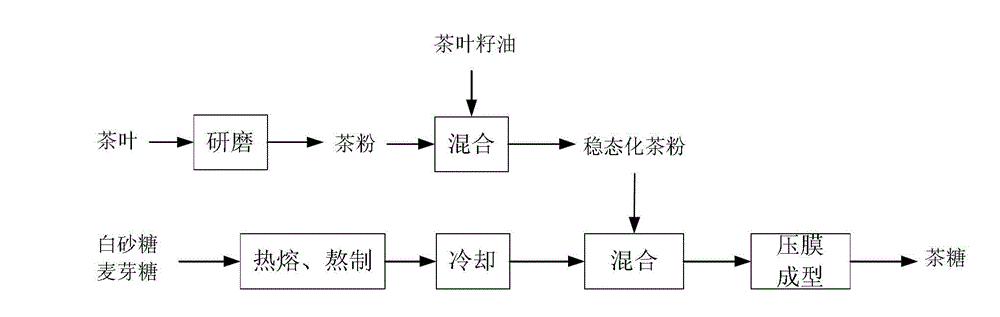

[0027] according to figure 1 Process shown for tea confectionery making.

[0028] (1) Preparation of micronized tea powder: 100g of dry green tea leaves are placed on a mill with a rotating speed of 1000-1500r / min, a grinding time of 6 hours, and a grinding particle size of 1000 mesh.

[0029] (2) Steady-state tea powder preparation: micronized tea powder and tea seed oil (chroma is Y35R3.5, acid value 1.0mg / g, peroxide value 4.8mmol / kg) are mixed by 0.5 weight ratio, and Mix and homogenize under the condition of 50-100r / min to form a stable tea powder, wherein the temperature for adding tea seed oil is 30°C.

[0030] (3) Cook sugar at a temperature of 140-160°C, boil sugar for 3-10 minutes, cool to 110°C, add auxiliary materials and stir evenly, and make candies according to requirements; the proportion of each component in the candy is: white sugar 70g, maltose 30g, auxiliary materials such as The total amount of sugar alcohol, peppermint oil, etc. is 5g, and the stabilize...

Embodiment 2

[0032] according to figure 1 Process shown for tea confectionery making.

[0033] (1) Preparation of micronized tea powder: put 200g of fresh tea leaves on a mill with a rotating speed of 1000-1500r / min, grinding time of 8 hours, and a grinding particle size of 50 mesh.

[0034] (2) Preparation of stable tea powder: micronized tea powder and tea seed oil (chroma is Y34R3.0, acid value 0.8mg / g, peroxide value 4.5mmol / kg.) After mixing by 1 weight ratio, Mix and homogenize under the condition of rotating speed 50-100r / min to form stable tea powder, wherein the temperature for adding tea seed oil is 40°C.

[0035] (3) Cook sugar at a temperature of 140-160°C, boil sugar for 3-10 minutes, cool to 110°C, add auxiliary materials and stir evenly, and make candies according to requirements; the proportion of each component in the candy is: white sugar 70g, maltose 30g, auxiliary materials such as The total amount of sugar alcohol, peppermint oil, etc. is 5g, and the stabilized tea p...

Embodiment 3

[0037] according to figure 1 Process shown for tea confectionery making.

[0038] (1) Preparation of micronized tea powder: put 200g of fresh tea leaves on a mill with a rotating speed of 1000-1500r / min, grinding time of 8 hours, and a grinding particle size of 50 mesh.

[0039] (2) Steady-state tea powder preparation: micronized tea powder and tea seed oil (chromaticity is Y32R3.5, acid value 0.8mg / g, peroxide value 4.3mmol / kg.) After mixing by 1.5 weight ratio, in Mix and homogenize under the condition of rotating speed 50-100r / min to form stable tea powder, wherein the temperature for adding tea seed oil is 50°C.

[0040] (3) Cook sugar at a temperature of 140-160°C, boil sugar for 3-10 minutes, cool to 110°C, add auxiliary materials and stir evenly to make candies as required; the proportion of each component in the candy is: white granulated sugar 65g, maltose 35g, auxiliary materials such as The total amount of sugar alcohol, peppermint oil, etc. is 5g, and the stabili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Pov | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com