Carbon monoxide detector for sulfur hexafluoride electric equipment

A technology of electrical equipment and sulfur hexafluoride, which is applied in the field of carbon monoxide detectors for sulfur hexafluoride electrical equipment, can solve the problems of inability to detect low-temperature hidden dangers early, difficult to detect insulation defects, and social and economic losses, so as to improve accuracy and Long service life, simple structure and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

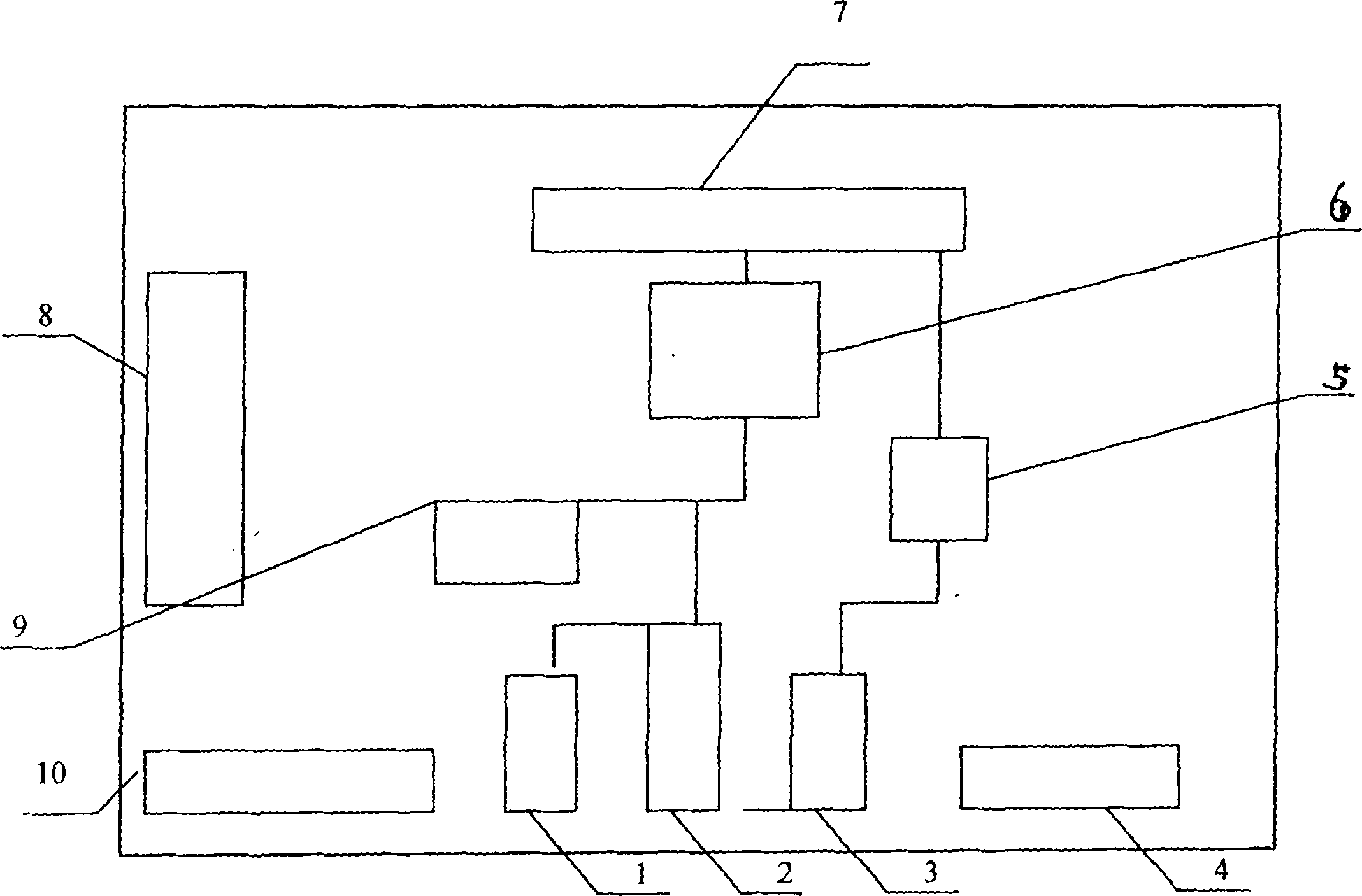

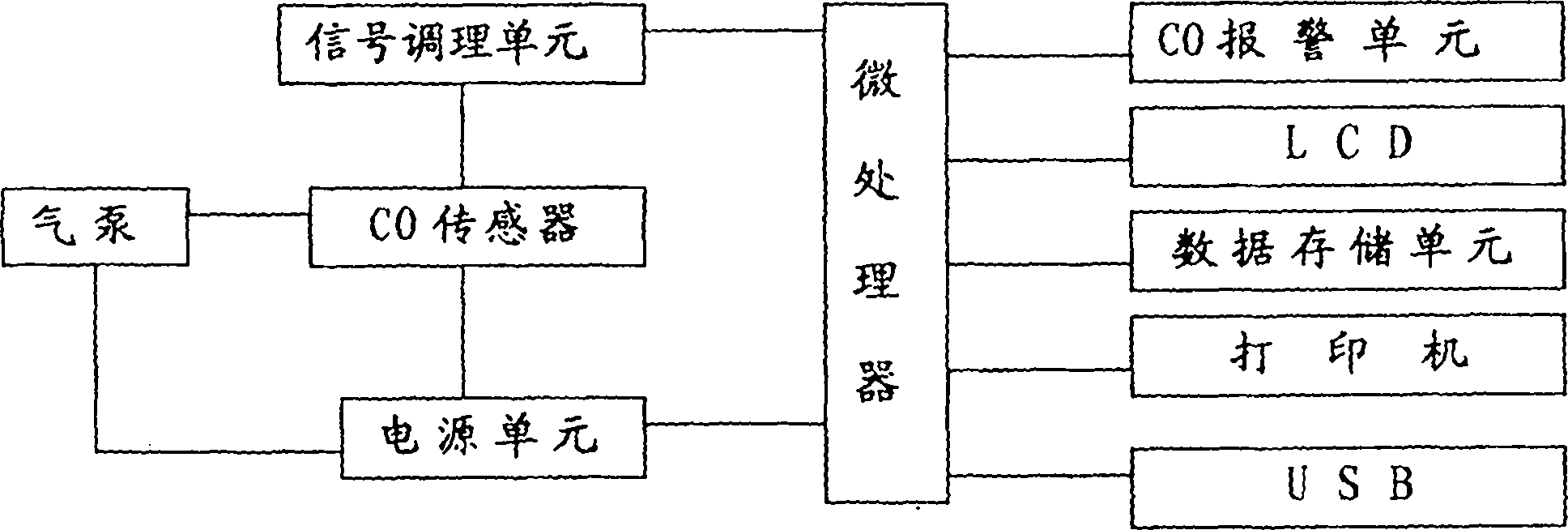

[0018] Please refer to the attached picture, the measured SF 6 The outlet of the exhaust valve of electrical equipment is connected to the inlet 1 of the detector through the air guide tube. After adjusting the set flow rate through the needle valve 2, it enters the CO electrochemical sensor 6, where a chemical reaction occurs, and an electrical signal corresponding to the CO concentration is output. , sent to the microprocessor and the A / D converter (electronic circuit board 8) through the conditioning unit, the analog signal is converted into a digital quantity, the logic processing and judgment are performed by the microprocessor, and the detected instant value is displayed by the LCD 10, and store the detected data. When the concentration of CO exceeds the normal value, the microcomputer processing will make judgments on the detection results and put forward corresponding treatment opinions. The detected gas enters the flow sensor 5 from the electrochemical sensor to dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com