Abrasion-resistant heat shock resistant impeller type fluid mechanical blade and preparation method

A fluid machinery and impeller-type technology, which is applied in the direction of mechanical equipment, liquid fuel engines, and components of pumping devices for elastic fluids, etc., and can solve problems such as wear protection measures for flow-passing components, coating peeling, and different thermodynamic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

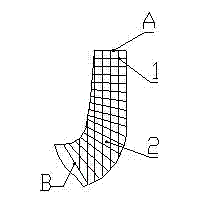

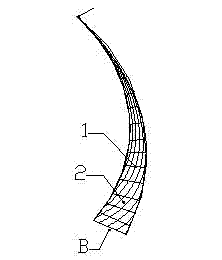

[0011] Such as figure 1 , figure 2 , taking the pump as an example, when the impeller rotates under the driving force, the impeller does work on the conveying medium, and the conveying medium undergoes centrifugal rotation in the impeller, and a local low pressure is generated at the inlet B of the impeller, and the air bubbles contained in the medium overflow and cause cavitation. Abrasion of pump blade surfaces. The conveying medium is sucked in from the impeller inlet B, discharged from the impeller outlet A, and when it reaches the outlet A, it has the maximum pressure. After the medium leaves the impeller, the flow space increases rapidly, the flow velocity and static pressure decrease rapidly, and cavitation occurs near the impeller outlet, causing serious damage to the surface of the blade outlet.

[0012] When the conveying medium contains abrasive grains, the abrasive grains will have a violent impact on the flow-passing parts, causing the surface of the material t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com