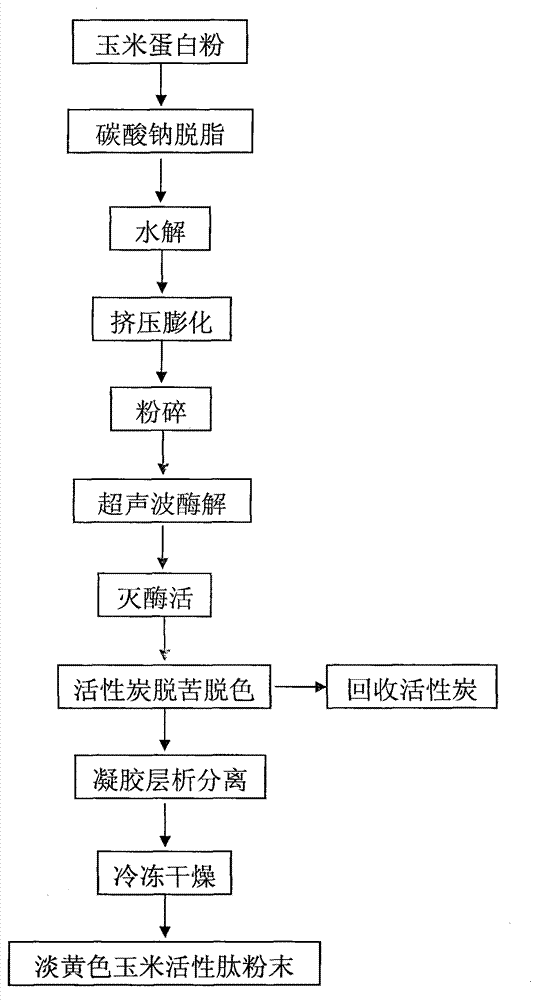

Preparation method of corn active peptides

An active peptide, corn technology, applied in the biological field, can solve the problems of restricting development and high cost, and achieve the effects of low price, improved digestibility and improved protein conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Pretreatment: Put 100g of corn gluten powder into a miniature plant sample pulverizer with a crushing chamber diameter of 105mm and a rotating speed of 1000r / min for pulverization, and sieve with an 80-mesh sieve. In the oscillating reactor, use anhydrous sodium carbonate with a mass concentration of 50g / L, add 20mL / g, treat for 15min, then centrifuge at 6000rpm / min for 15min, repeat washing with water for 3 times, centrifuge at 6000rpm / min for 15min and then hydrolyze;

[0023] (2) Extrusion and puffing: the zein is modified by using a split twin-screw extruder, the die hole diameter is 15mm, the sleeve temperature is 85°C, the moisture content of the material is 10%, and the screw speed is 120r / min;

[0024] (3) Ultrasonic enzymolysis: take puffed corn gluten powder with a mass fraction of 10%, break the wall for 15 minutes under 420W ultrasonic conditions, stir at 50-55°C, adjust the pH value to 9-10, add 3% enzyme, and use it under this condition Alcalase alkali...

Embodiment 2

[0030] (1) Pretreatment: Put 100g of corn gluten powder into a miniature plant sample pulverizer with a crushing chamber diameter of 105mm and a rotating speed of 1000r / min for pulverization, and sieve with an 80-mesh sieve. In the shaking reactor, use anhydrous sodium carbonate with a mass concentration of 60g / L, add 10mL / g, treat for 15min, then centrifuge at 6000rpm / min for 15min, wash with water repeatedly for 3 times, centrifuge at 6000rpm / min for 15min and then hydrolyze;

[0031] (2) Extrusion and puffing: the zein is modified by using a split twin-screw extruder with a die hole diameter of 15mm, a sleeve temperature of 85°C, a moisture content of the material of 12%, and a screw speed of 120r / min;

[0032] (3) Ultrasonic enzymolysis: take puffed corn gluten powder with a mass fraction of 12%, break the wall for 12 minutes under 430W ultrasonic conditions, stir at 50-55°C, adjust the pH value to 9-10, add 4% enzyme, and use it under this condition Alcalase alkaline endo...

Embodiment 3

[0038] (1) Pretreatment: Put 100g of corn gluten powder into a miniature plant sample pulverizer with a crushing chamber diameter of 105mm and a rotating speed of 1500r / min for pulverization, and sieve with an 80-mesh sieve. In the oscillating reactor, use anhydrous sodium carbonate with a mass concentration of 60g / L, add 15mL / g, treat for 15min, then centrifuge at 7000rpm / min for 13min, repeat washing with water for 3 times, centrifuge at 7000rpm / min for 13min and then hydrolyze;

[0039] (2) Extrusion and puffing: the zein is modified by using a split twin-screw extruder, the die hole diameter is 15mm, the sleeve temperature is 85°C, the moisture content of the material is 15%, and the screw speed is 130r / min;

[0040] (3) Ultrasonic enzymolysis: take puffed corn gluten powder with a mass fraction of 13%, break the wall for 13 minutes under 440W ultrasonic conditions, stir at 50-55°C, adjust the pH value to 9-10, add 4% enzyme, and use it under this condition Alcalase alkali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com