Method for treating acid uranium-bearing wastewater by utilizing modified chitosan adsorbents

A chitosan and adsorbent technology, applied in the field of uranium adsorption in acidic uranium-containing wastewater, can solve the problems of high operating costs and raw material costs, complex uranium-containing wastewater treatment process, etc., and achieve high removal rate and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Select 50ml of uranium-containing wastewater solution with a concentration of 63.0mg / L (if there is organic matter in the wastewater, remove the organic matter in the solution first to avoid interfering with the adsorption of the adsorbent or the concentration test), adjust the pH to 4-5, add to 200mg CATT In a Erlenmeyer flask, the shaker was adsorbed for 72 hours, and the concentration of uranium in the solution before and after adsorption was measured. The calculated adsorption capacity of the adsorbent CATT for uranium is 15.1 mg / g (dry), and the removal rate of uranium in the solution is 95.9%.

[0017] 2mol / L HCl was chosen as the desorbent for chitosan-based adsorbent CATT uranium. The adsorbent CATT saturated with uranium was desorbed by 2mol / L HCl, and the desorption rate was 97%.

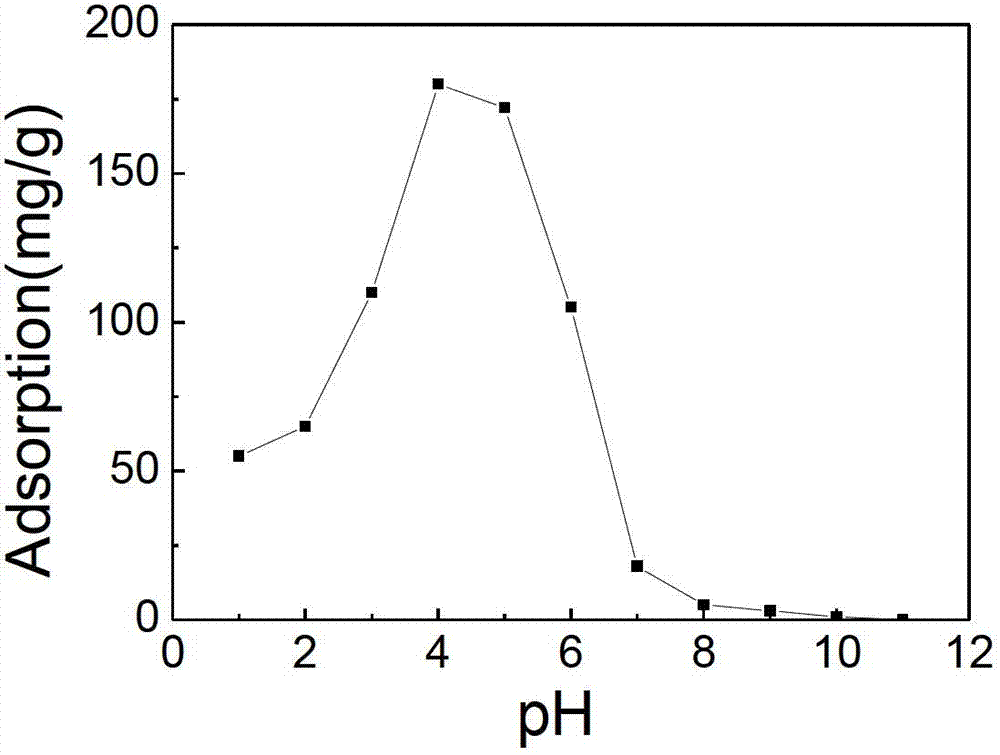

[0018] The effect of solution pH on the adsorption performance of CATT uranium, such as figure 1 shown. The adsorbent CATT has a high adsorption capacity in the pH range of 3~6, ...

Embodiment 2

[0020] Select 50ml of uranium-containing wastewater solution with a concentration of 35.0mg / L (if there is organic matter in the wastewater, remove the organic matter in the solution first to avoid interfering with the adsorption of the adsorbent or the concentration test), adjust the pH to 4-5, add to 200mg CATT In a Erlenmeyer flask, the shaker was adsorbed for 72 hours, and the concentration of uranium in the solution before and after adsorption was measured. After calculation, the adsorption capacity of the adsorbent CATT for uranium is 8.6 mg / g (dry), and the removal rate of uranium in the solution is 98.3%.

Embodiment 3

[0022] Select 50ml of uranium-containing wastewater solution with a concentration of 6.26mg / L (if there is organic matter in the wastewater, remove the organic matter in the solution first to avoid interfering with the adsorption of the adsorbent or the concentration test), adjust the pH to 4-5, and add to 200mg CATT In a Erlenmeyer flask, the shaker was adsorbed for 72 hours, and the concentration of uranium in the solution before and after adsorption was measured. After calculation, the adsorption capacity of the adsorbent CATT for uranium is 1.5 mg / g (dry), and the removal rate of uranium in the solution is 95.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com