Method for removing magnesium and sulfate ion in salt lake brine of hexahydric salt-water system

A technology of sulfate ion and salt lake brine, which is applied in the field of inorganic salt chemical industry, can solve the problems of serious corrosion of equipment, large amount of evaporated water, and high cost, and achieve the effects of reducing labor costs, improving output and quality, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

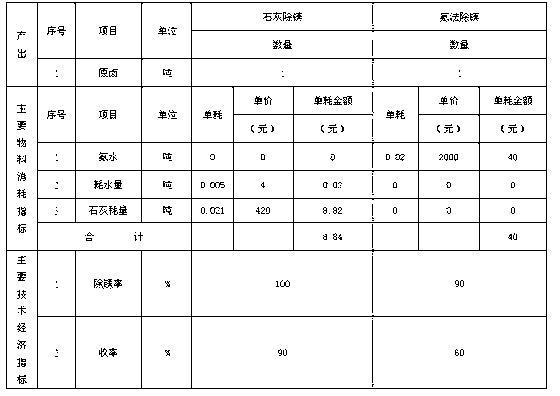

[0023] (2) Raw material: volume unit is l, weight unit is Kg.

[0024] Original halogen: that is, the natural salt lake contains 0.2-0.35% of potassium ions, 0.36-0.45% of magnesium ions, 14-15% of chloride ions, 1.5-2% of sulfate ions, 0.5-0.8% of nitrate ions, and 9-10% of sodium ions % of brine.

[0025] Quicklime: Available calcium, namely CaO% content > 75.00%.

[0026] Process method:

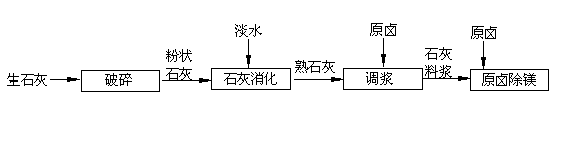

[0027] Such as figure 1 Shown:

[0028] ⑴ Crushing: Crush the quicklime with a block size of 15-60mm to a block size of 2-10mm, and put it into the crusher for crushing for 1-2 minutes to make it into 120-160 mesh powdered lime.

[0029] ⑵ Lime digestion: Mix the obtained powdered lime with fresh water according to mass: volume = 1kg: 0.6L. A lot of heat is released during the mixing process, and it becomes slaked lime after natural cooling.

[0030] (3) Slurry mixing: Mix the obtained slaked lime and raw halogen according to the ratio of mass:volume=1kg:2.5L, put the mixed slurry in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com