Modular heat pipe heat exchanger

A technology of heat exchangers and heat pipes, applied in heat exchange equipment, heat exchanger types, indirect heat exchangers, etc., can solve problems such as time-consuming, high operating costs, and production losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

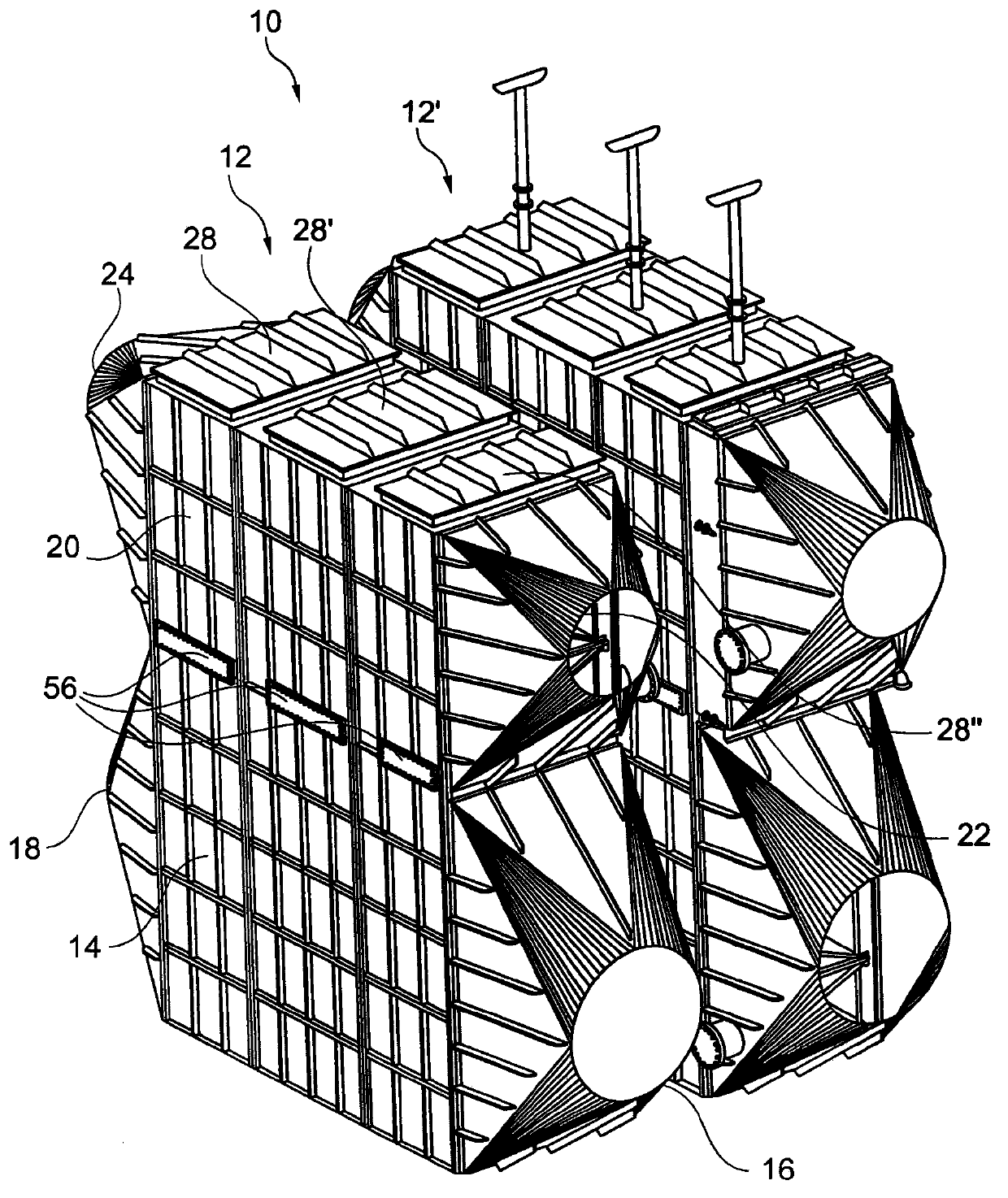

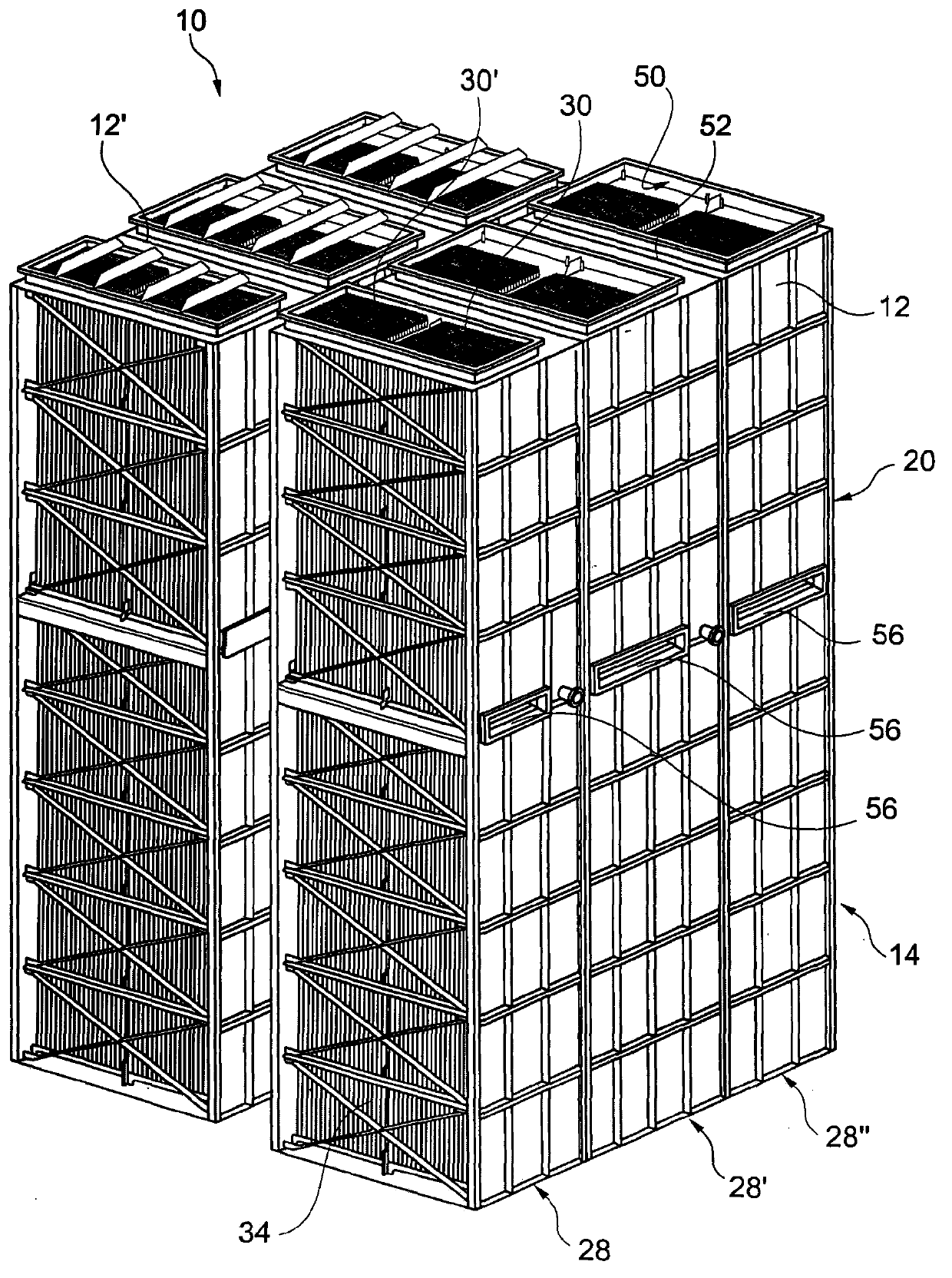

[0022] figure 1 A preferred embodiment of a heat pipe recovery system 10 according to the invention with two heat pipe heat exchangers 12, 12' is shown. One of the heat exchangers 12, 12' may be used to preheat the combustion gases, while the other of the heat exchangers 12, 12' may be used to preheat the combustion air.

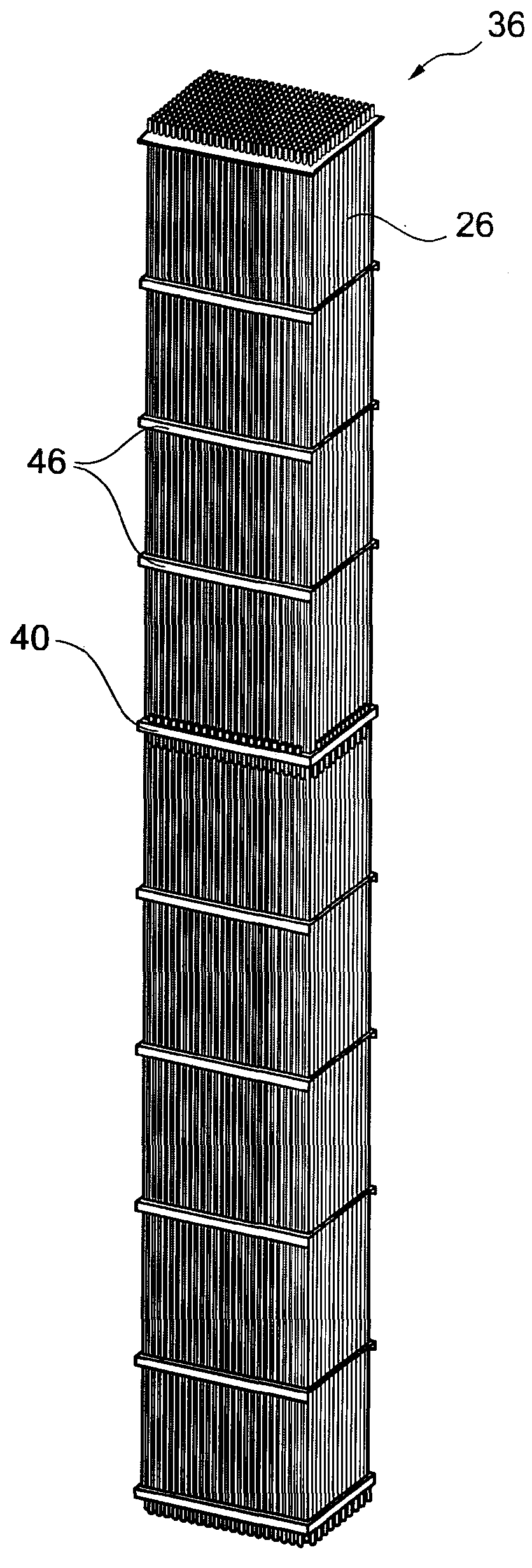

[0023] Each heat exchanger 12, 12' includes a first chamber 14 having a first port 16 and a second port 18 and a second chamber 20 having a third port 22 and a fourth port 24. In the embodiment shown in the figures, the second chamber 20 is arranged vertically above the first chamber 14 . A plurality of heat pipes 26 (typically several thousand) are arranged vertically in said first and second chambers 14 , 20 . These heat pipes 26 generally extend over the entire height of the second chamber 20, passing through the separating wall (in figure 1 not visible in ) from the second chamber 20 to the first chamber 14 and extends over the entire height of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com