Surface treatment device and method

A processing device and processing method technology, used in transportation and packaging, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems affecting the overall functionality of semiconductor components, pollution, and unusable range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Since the present invention discloses a surface treatment device and method, the accompanying drawings below show the structural representations related to the features of the present invention, and are not and need not be completely drawn according to the actual size, and it is stated in advance.

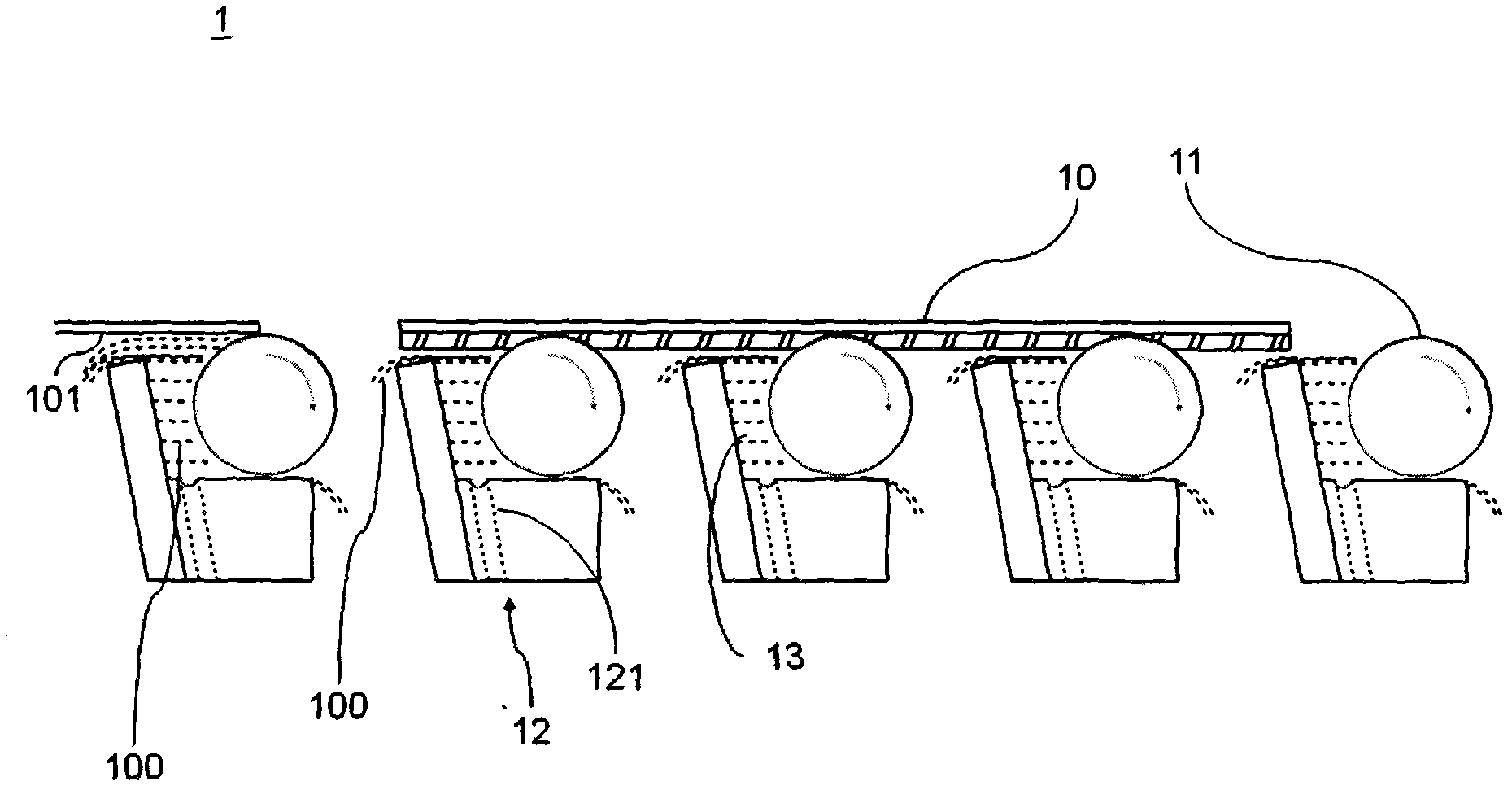

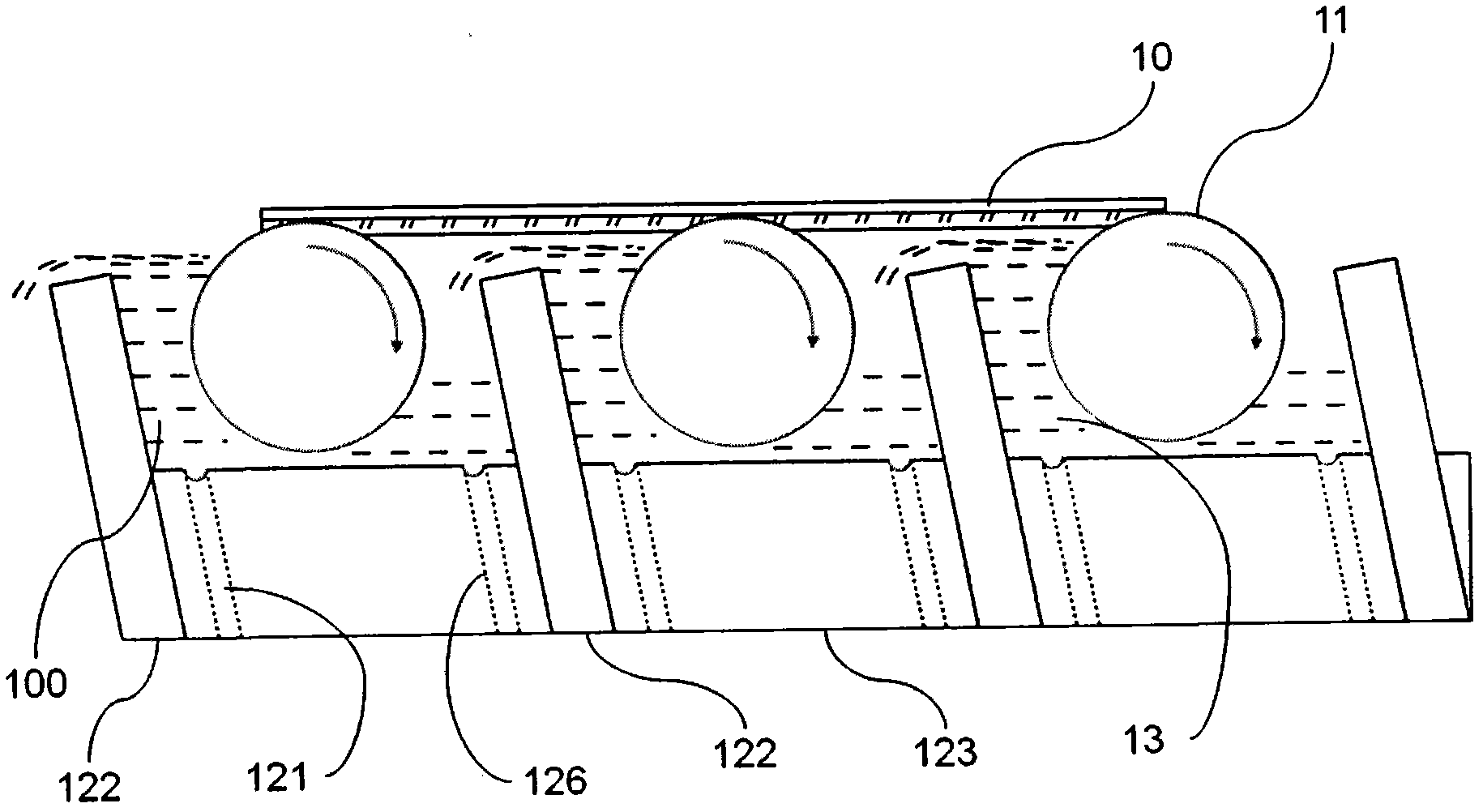

[0042] First please refer to figure 1 , The first embodiment of the present invention provides a substrate surface treatment device 1 , including a plurality of conveying devices 11 and at least one fountain seat 12 . The conveying device 11 can be used to convey the substrate 10, and the conveyed substrate 10 has a lower surface 101; the spring seats 12 are respectively arranged at intervals, and are respectively combined with the corresponding conveying device 11 to form the first liquid accumulation space 13, and each spring The seat 12 is provided with a liquid injection port 121, and each liquid injection port 121 communicates with its corresponding first liquid accumul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com