Power inductance element formed by molding and manufacturing method thereof

A technology of molding and power inductors, which is applied in the manufacture of electrical components, inductors/transformers/magnets, inductors with magnetic cores, etc., can solve the problem of affecting the degree of closeness, limiting automatic production, and the difficulty of producing magnetic heat shrinkable sleeves And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below through embodiments in conjunction with the accompanying drawings.

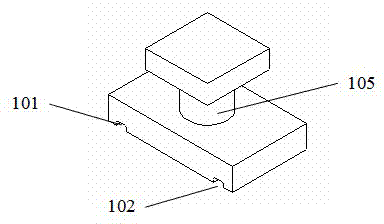

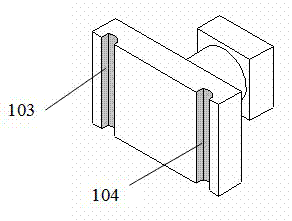

[0043] Such as Figure 1A1 , 1A2 As shown, the NiZn ferrite I-shaped magnetic core can be made by injection molding process, the magnetic permeability is preferably 3000~5000, and the saturation magnetic flux is 400~500mT. Preferably, there are two parallel electrode slots 101, 102 at the bottom of the magnetic core. The metallization layers 103 and 104 are preferably formed inside the electrode groove by a sputtering process.

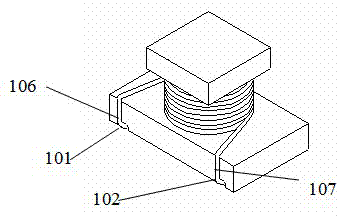

[0044] A winding machine can be used to wind the wire on the above-mentioned I-shaped magnetic core center column 105 . Such as Figure 1B As shown, preferably, the coil lead-out ends 106, 107 are received into the electrode slots 101, 102 after the coil winding product is completed.

[0045] Figure 1C It is a schematic diagram of the finished product formed after wrapping the winding with a magnetic plastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com