A Method of Checking Pipeline Assembly Based on Computer Aided Design

A computer-aided and pipeline technology, applied in calculation, special data processing applications, instruments, etc., can solve the problems of complex catheter space, heavy design workload, low design efficiency, etc., to reduce manufacturing costs, strict manufacturing tolerance requirements, Improve the effectiveness of standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

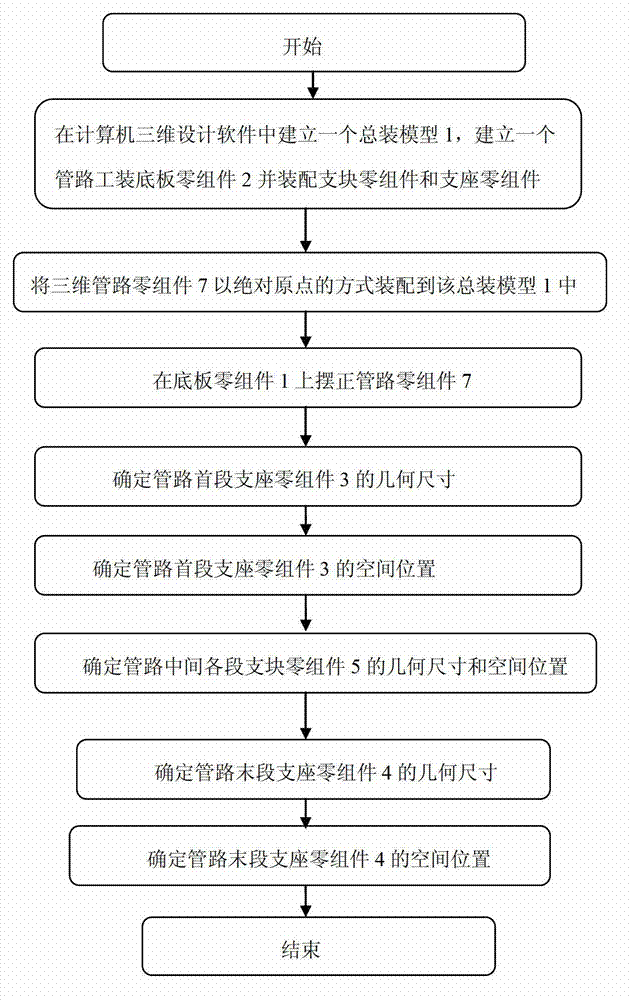

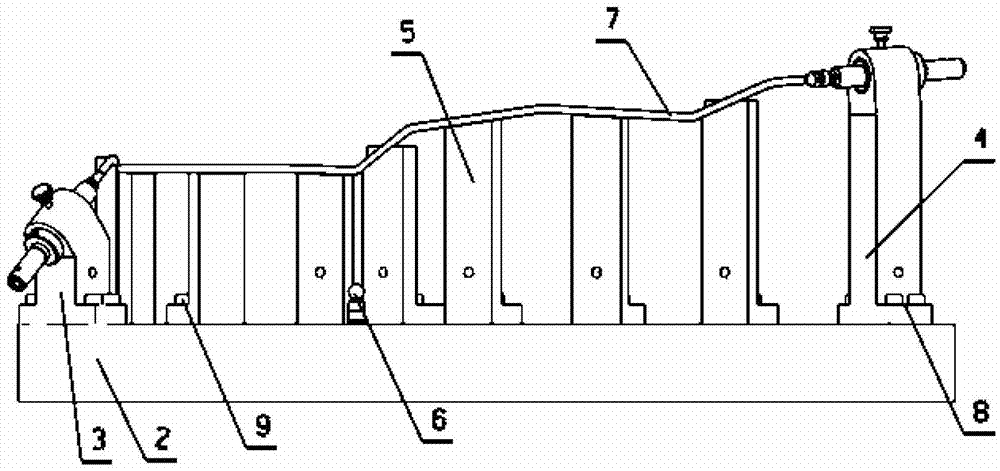

[0071] 1. Establish a general assembly model 1 in the computer 3D design software, and establish a pipeline tooling base plate component 2 in the general assembly model 1, and ensure that the intersection of the lower left corner of the upper surface of the base plate component 2 coincides with the absolute origin of the final assembly model 1, The length direction of base plate components 2 coincides with the X axis of the absolute coordinate system of assembly model 1, and the width direction of base plate components 2 coincides with the Y axis of the absolute coordinate system of assembly model 1. An XOY plane is formed on the upper surface of base plate components 2. Component 2 is assembled with the first support component 3, the last support component 4 and the middle support block component 5 to ensure that the first support component 3, the last support component 4 and the middle support block The lower surface of component 5 is bonded to the upper surface of base compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com